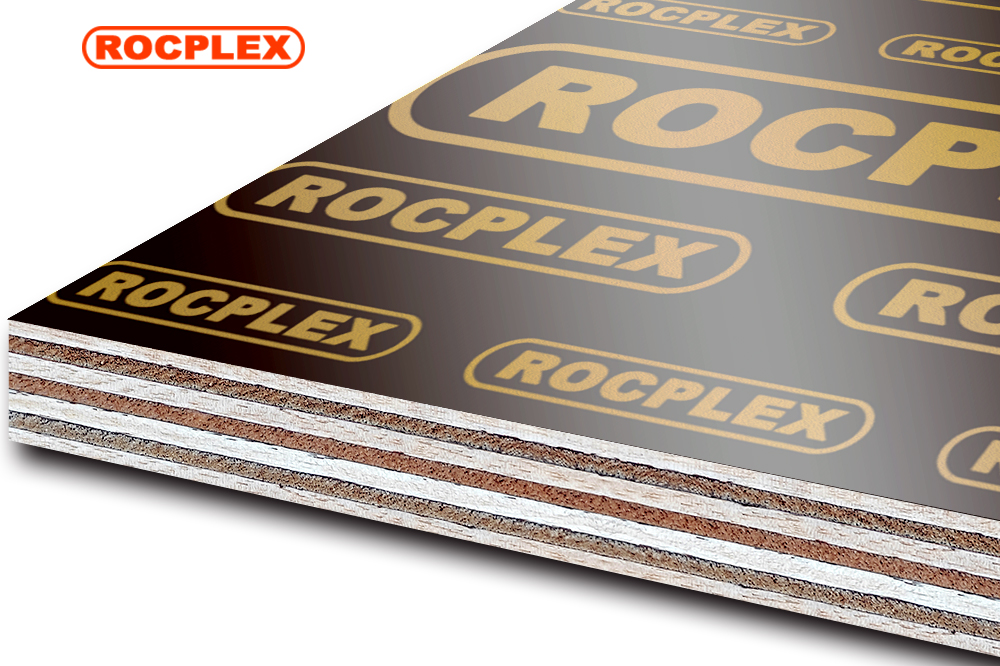

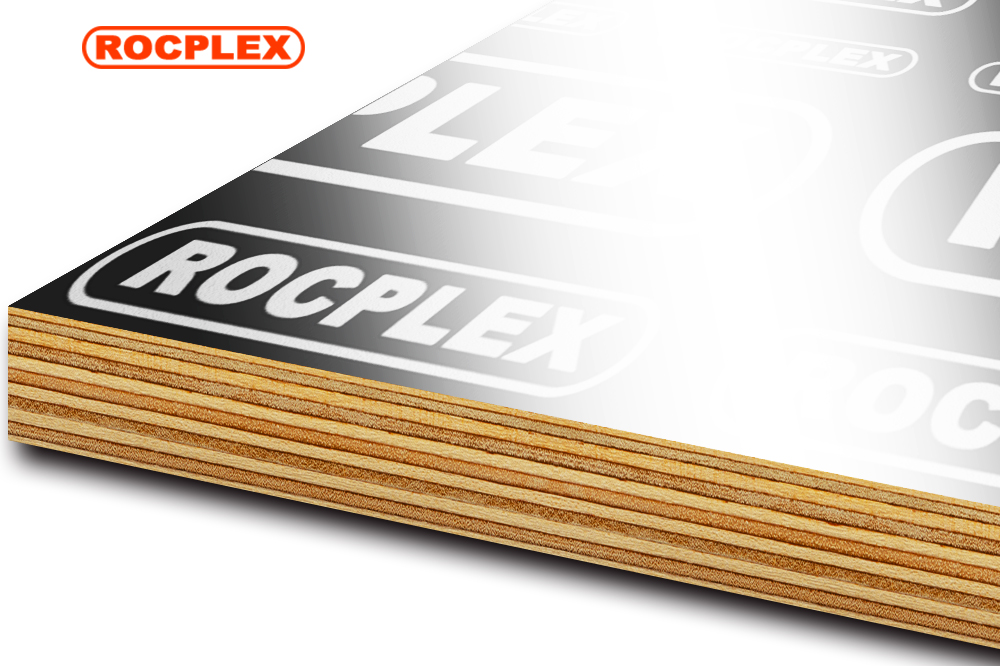

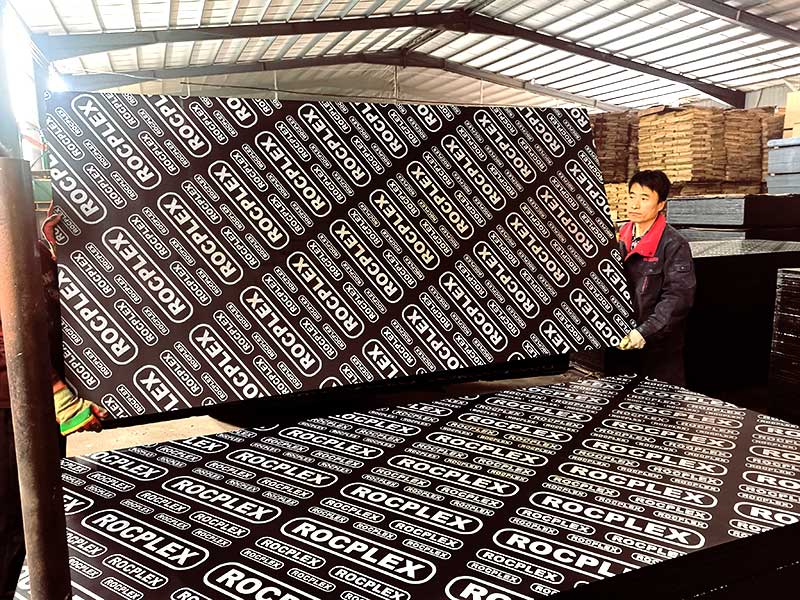

Premium Quality 12mm Film-Faced Plywood to Enhance Construction Excellence

When it comes to construction and woodworking projects that demand resilience and a flawless finish, 12mm film-faced plywood stands out as a versatile and indispensable material. With its unique properties and various applications, this type of plywood has become a staple in the construction industry.

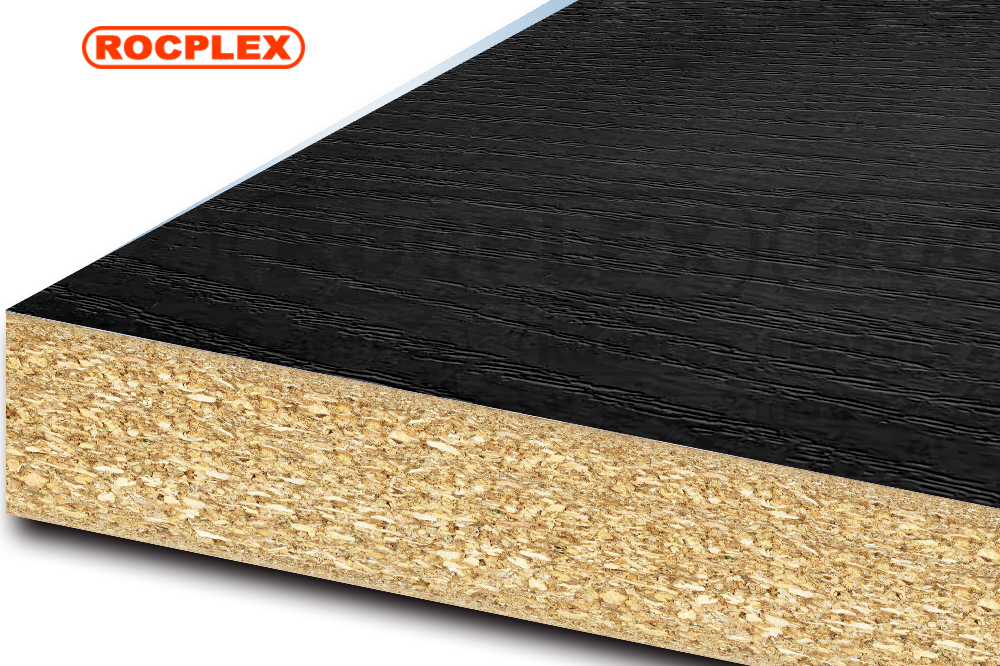

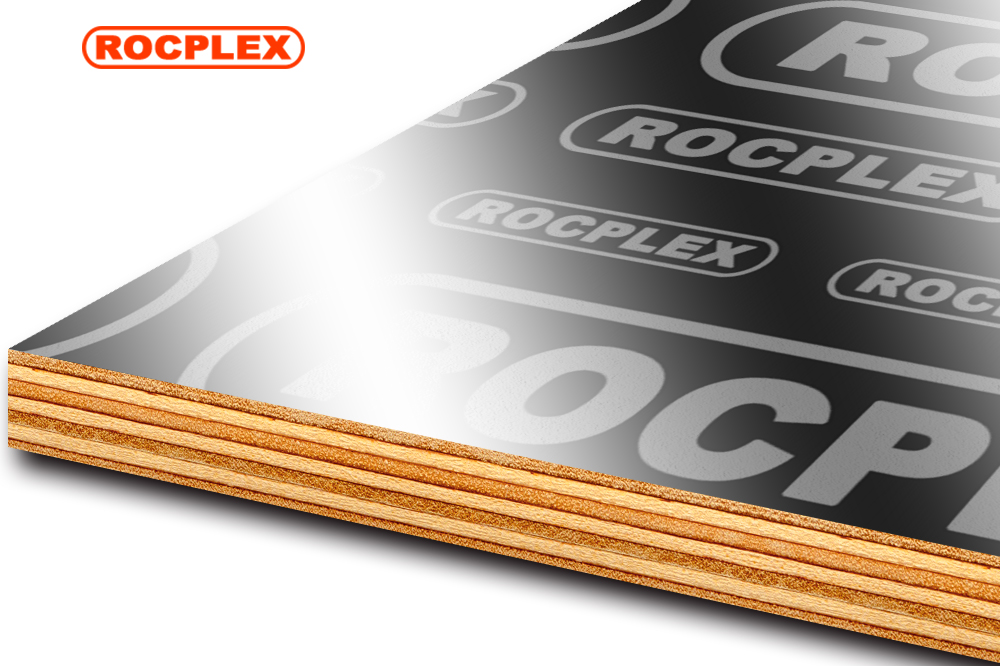

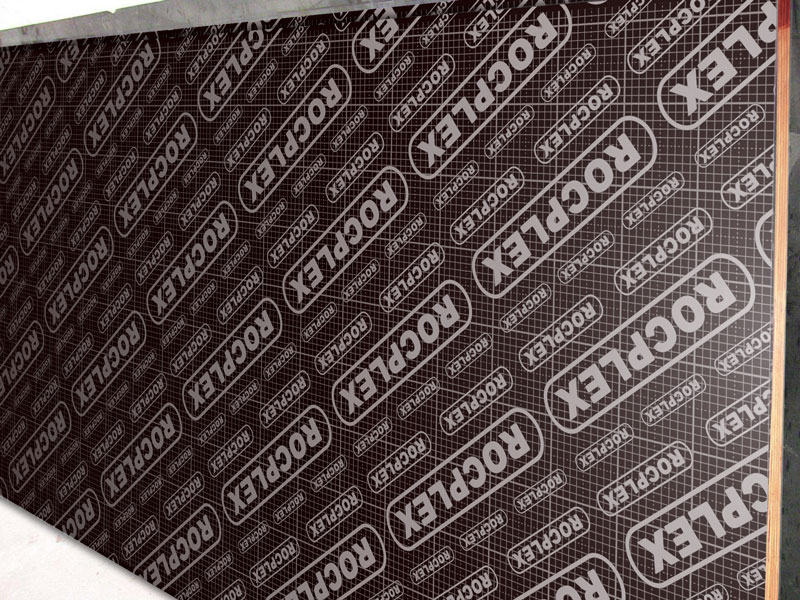

12mm film-faced plywood is a type of engineered wood that consists of multiple layers or veneers bonded together with high-quality adhesive. What sets it apart is the protective film layer on one or both sides, usually made of phenolic resin or melamine. This film provides exceptional durability, water resistance, and a smooth surface, making it ideal for a range of applications.

ROCPLEX 12mm Film-Faced Plywood Technical characteristics

| Sr No. | Property | Unit | Test Method | Value Of Test | Result | |

| 1 | Moisture Content | % | EN 322 | 7.5 | Check out | |

| 2 | Density | kg/m3 | EN 323 | 690 | Check out | |

| 3 | Bonding Quality | Bonding Quality | Mpa | EN 314 | 1.68-0.81 | Check out |

| 4 | Bonding Quality | Damage Rate | % | EN 314 | 85% | Check out |

| 5 | Bending Modulus of Elasticity | Longitudinal | Mpa | EN 310 | 6997 | Check out |

| 6 | Bending Modulus of Elasticity | Lateral | Mpa | EN 310 | 6090 | Check out |

| 7 | Longitudinal | Mpa | EN 310 | 59 | Check out | |

| 8 | Lateral | Mpa | EN 310 | 43.77 | Check out | |

| 9 | Cycle Life | About 15-25 Repeated Using Times According To Projects By Formwork Application | ||||

exterior plywood

Benefits and Applications:

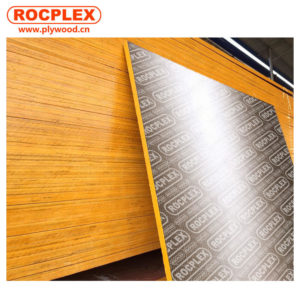

- Construction and Formwork: One of the primary uses of 12mm film-faced plywood is in concrete formwork. The film-facing prevents concrete from adhering to the surface, ensuring easy removal once the concrete sets. This not only saves time but also extends the lifespan of the plywood, making it a cost-effective choice.

- Durability: The protective film layer shields the plywood from moisture, weather elements, and mechanical stress. This makes 12mm film-faced plywood an excellent option for outdoor construction, such as scaffolding, hoardings, and temporary structures.

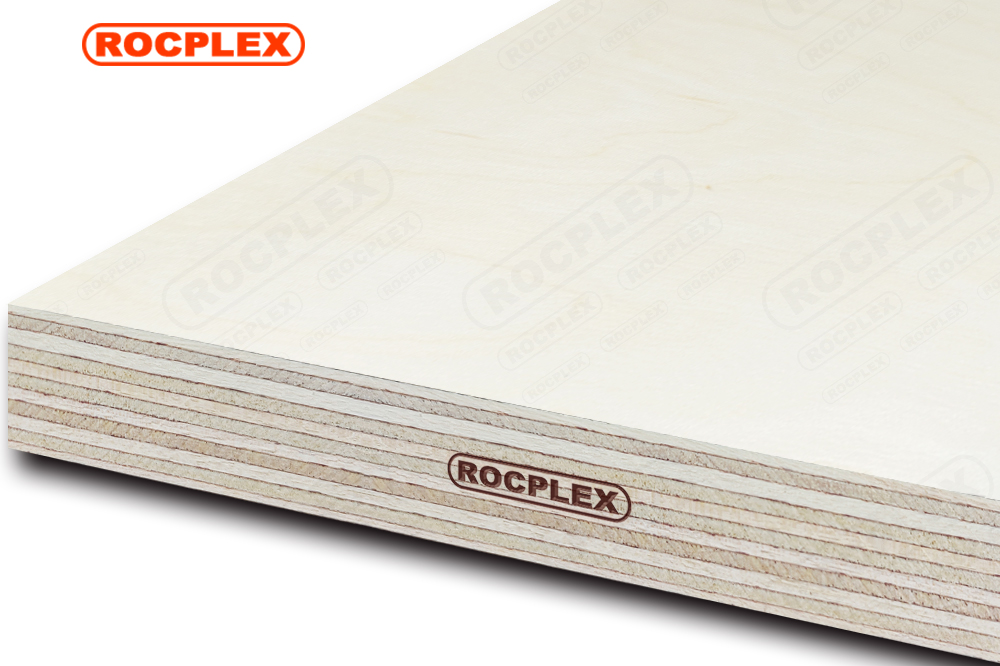

- Smooth Finish: The smooth and consistent surface of the plywood translates to superior finishing in projects like furniture making, cabinetry, and interior décor. This reduces the need for extensive sanding and finishing work.

Tips for Using 12mm Film-Faced Plywood:

- Proper Handling: Store plywood sheets in a dry, flat area to maintain their integrity and prevent warping.

- Cutting and Fastening: Use appropriate cutting tools to prevent splintering of the film layer. Stainless steel or coated fasteners are recommended to prevent rust stains.

- Sealing Edges: Applying edge sealant helps protect the plywood from moisture penetration and enhances its lifespan.

- Reuse: While 12mm film-faced plywood is designed for multiple uses, its reusability depends on how well it is maintained. Careful removal of formwork and cleaning after use contribute to its extended life.

exterior plywood

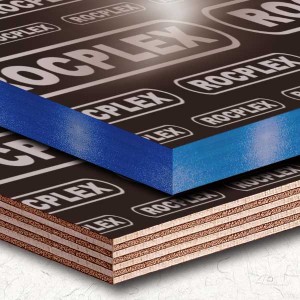

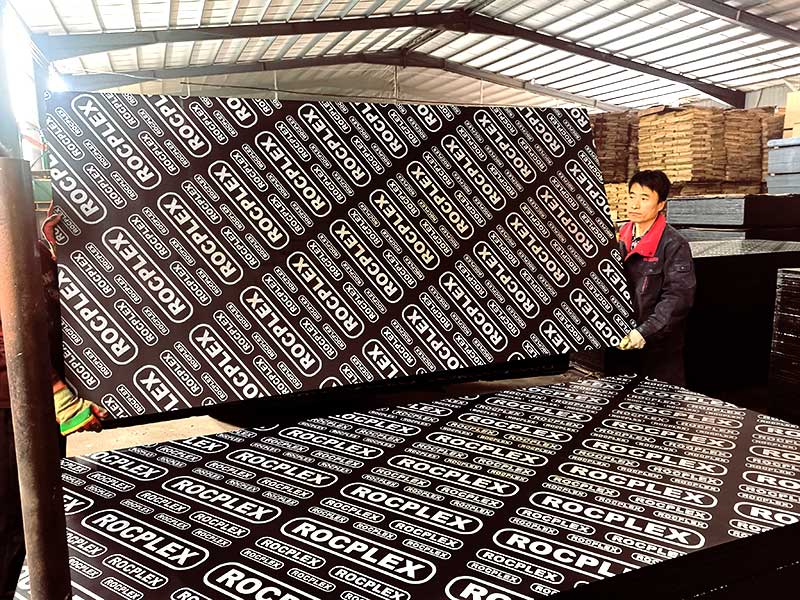

ROCPLEX Brown Film Faced Plywood Save Time, Labor, and Cost

|

ROCPLEX Film faced plywood Save cost |

||

|

Be special for phenolic glue and film |

The smooth plywood film-faced plywood can be disassembled and used repeatedly for both faces, saving 25% of the cost. |

|

|

Optimization for the special grade of core |

||

|

Be special for adhesive |

||

|

ROCPLEX Film faced plywood Shorten the duration |

||

|

Excellent effect of de-molding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

||

|

Be easy to incise and blend |

||

|

ROCPLEX Film faced plywood the high-quality casting |

||

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

||

|

The edges are polished carefully |

||

ROCPLEX 12mm Film-Faced Plywood Packing and Loading

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

the best plywood for subfloor

ROCPLEX Brown Film-Faced Plywood

ROCPLEX 12mm film-faced plywood undergoes stringent quality control measures to meet industry standards and ensure consistent performance. It is manufactured using high-quality raw materials and advanced production techniques to guarantee reliability and longevity.

Brown Film Faced Plywood 12mm FAQ

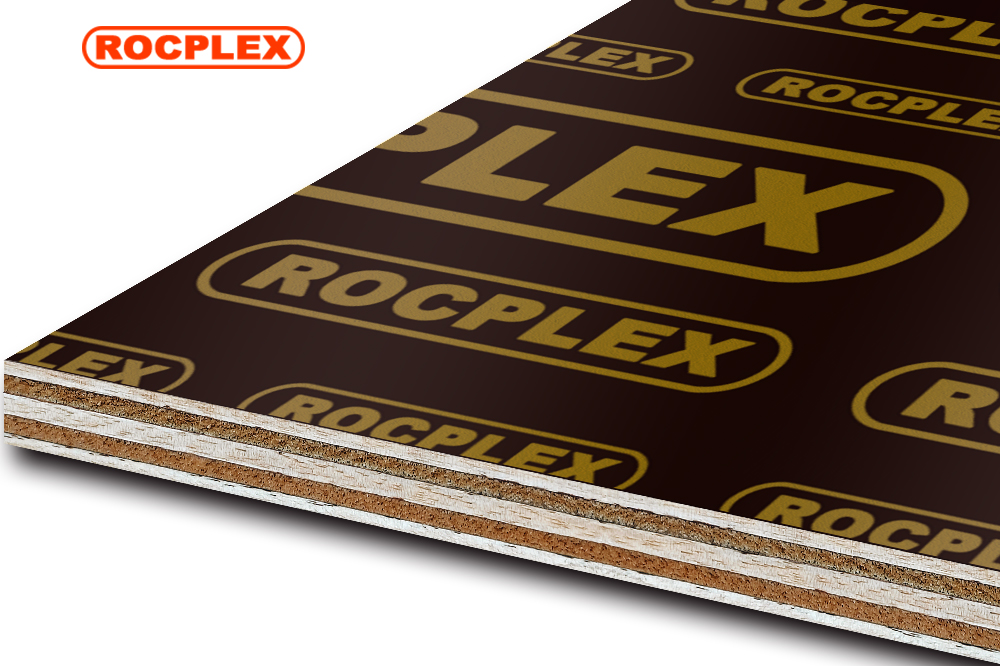

Q: What is brown film-faced plywood?

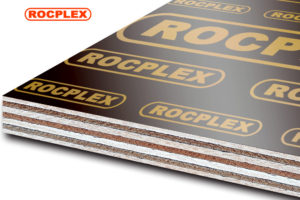

A: Brown film-faced plywood is a type of plywood that has a brown phenolic film on its surface. This film is used to protect the plywood from moisture and other external factors.

Q: What are the dimensions of brown film-faced plywood?

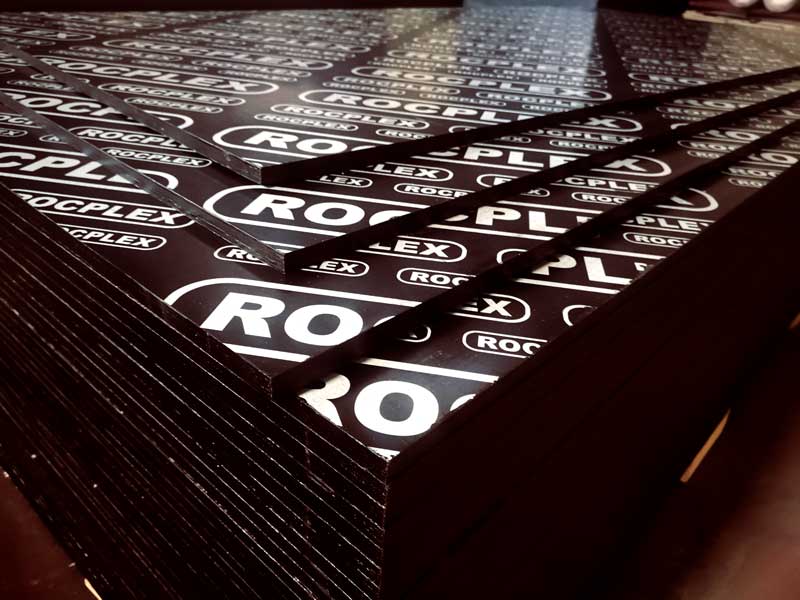

A: Brown film-faced plywood comes in various dimensions, but the most common size is 1220mm x 2440mm (4′ x 8′). The thickness can range from 9mm to 21mm.

Q: What are the advantages of using brown film-faced plywood?

A: Brown film-faced plywood is strong, durable, and resistant to water and other external factors. It can be used in various construction projects, especially where strength and durability are required. It also has a smooth surface, making it ideal for use in concrete formwork.

Q: How is brown film-faced plywood made?

A: Brown film-faced plywood is made by bonding multiple layers of wood veneers together with a strong adhesive. The brown phenolic film is then added to the surface to protect the plywood from moisture and other external factors.

Q: What is the weight of brown film-faced plywood?

A: The weight of brown film-faced plywood can vary depending on its thickness. Generally, 12mm thick brown film-faced plywood can weigh around 26-28kg.