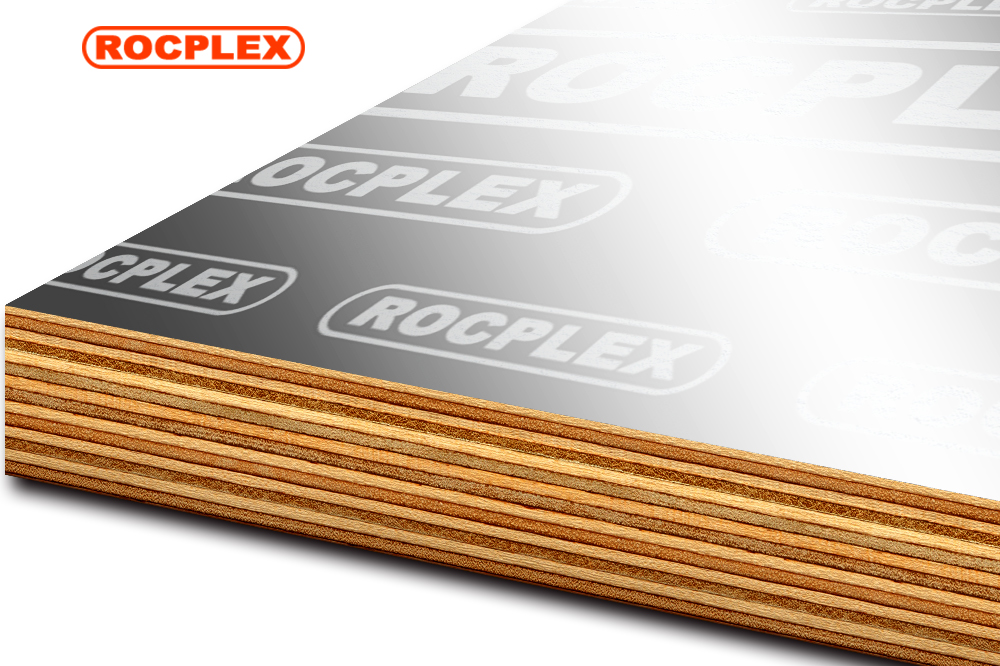

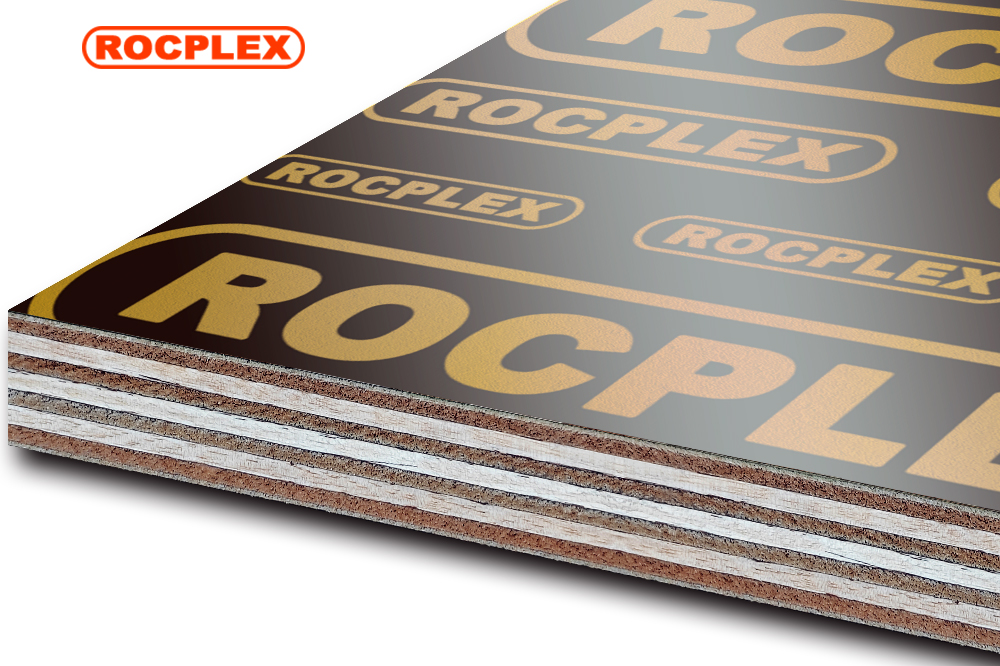

Shuttering Plywood 21mm Phenolic Exterior Plywood For Concrete Form use Board

Introducing our high-quality Shuttering Plywood, specifically designed for concrete formwork and construction applications. This 21mm Phenolic Exterior Plywood is the perfect choice for professionals seeking a robust and dependable board that can withstand the demanding requirements of concrete casting and deliver exceptional performance on the job site.

Crafted with precision and engineered for strength, our Shuttering Plywood offers a sturdy construction that ensures excellent load-bearing capacity and dimensional stability. With a thickness of 21mm, this plywood provides exceptional strength while maintaining flexibility, making it easy to handle and install while ensuring structural integrity.

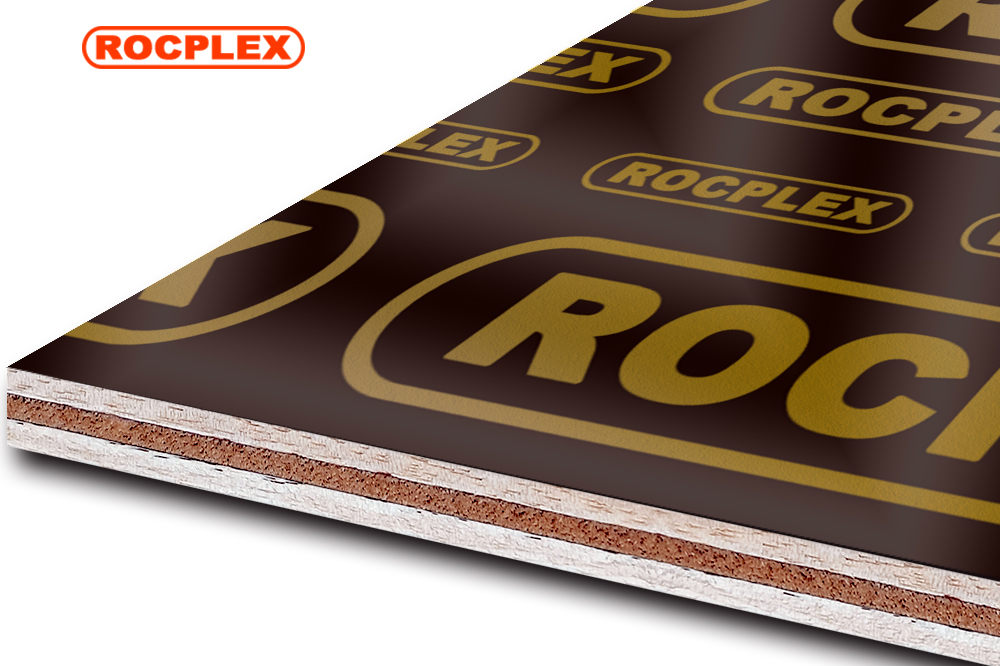

One of the standout features of our Shuttering Plywood is its phenolic exterior surface. The surface is coated with a premium-grade phenolic film renowned for its water resistance, durability, and resistance to wear and tear. The phenolic film acts as a protective barrier, safeguarding the plywood from moisture, weather elements, and chemicals commonly found in concrete, ensuring prolonged usability and an extended lifespan.

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

7.5 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

690 |

Check out |

|

|

3 |

Bonding Quality |

Bonding Quality |

Mpa |

EN 314 |

Max: 1.68 Min: 0.81 |

Check out |

|

Damage Rate |

% |

85% |

Check out |

|||

|

4 |

Bending Modulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6997 |

Check out |

|

Lateral |

6090 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

59 |

Check out |

|

|

Lateral |

43.77 |

Check out |

||||

|

6 |

Cycle Life |

About 15-25 Repeated Using Times According To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

605 |

Check out |

|

|

3 |

Bonding Quality |

Bonding Quality |

Mpa |

EN 314 |

Max: 1.59 Min: 0.79 |

Check out |

|

Damage Rate |

% |

82% |

Check out |

|||

|

4 |

Bending Modulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6030 |

Check out |

|

Lateral |

5450 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

57.33 |

Check out |

|

|

Lateral |

44.79 |

Check out |

||||

|

6 |

Cycle Life |

About 12-20 Repeated Using Times According To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8.4 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

550 |

Check out |

|

|

3 |

Bonding Quality |

Bonding Quality |

Mpa |

EN 314 |

Max: 1.40 Min: 0.70 |

Check out |

|

Damage Rate |

% |

74% |

Check out |

|||

|

4 |

Bending Modulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

5215 |

Check out |

|

Lateral |

4796 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

53.55 |

Check out |

|

|

Lateral |

43.68 |

Check out |

||||

|

6 |

Cycle Life |

About 9-15 Repeated Using Times According To Projects By Formwork Application |

||||

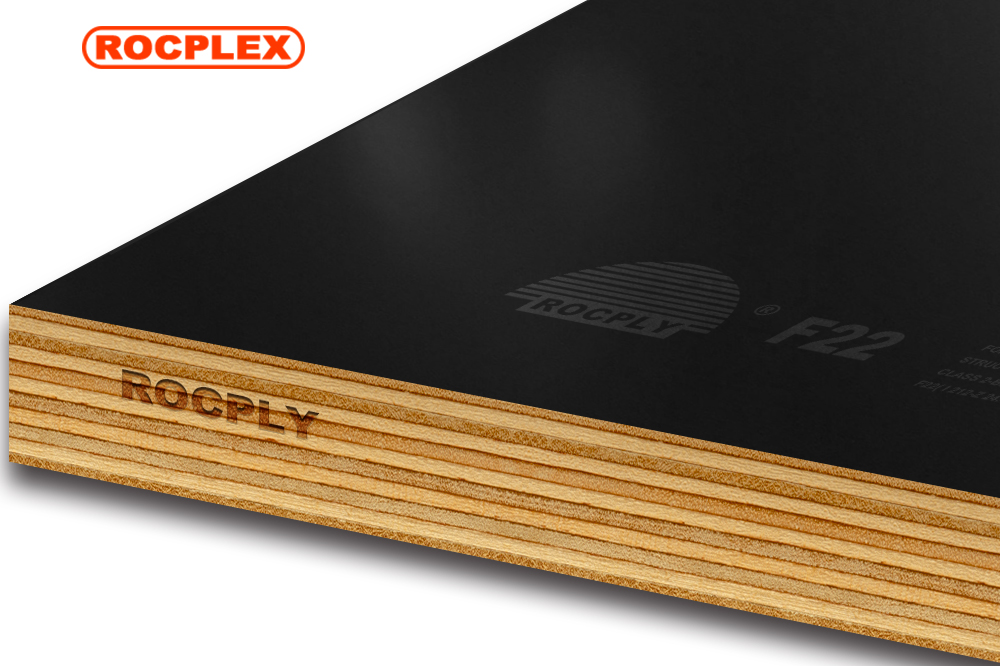

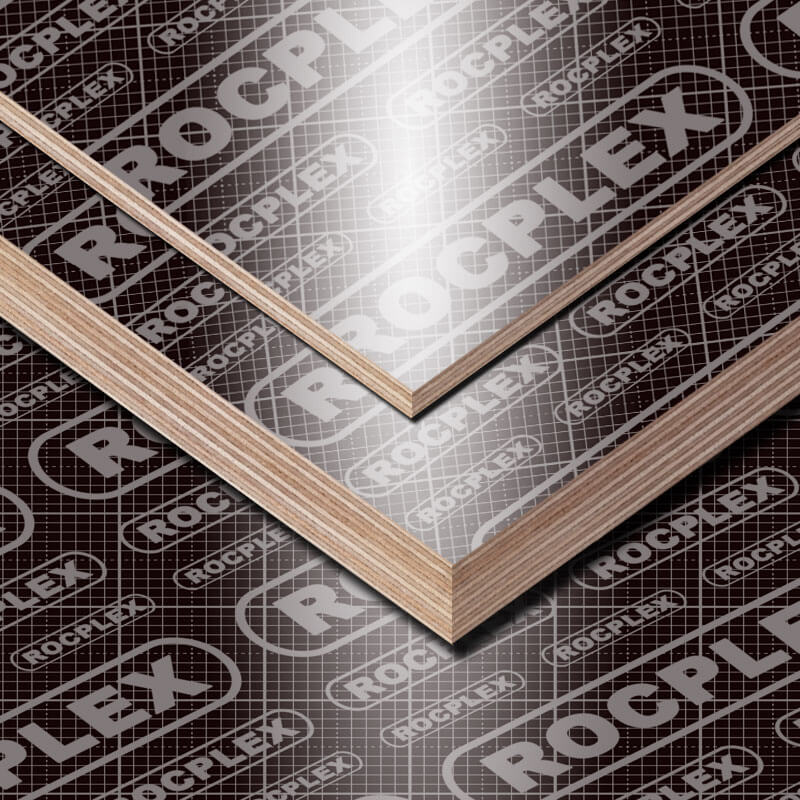

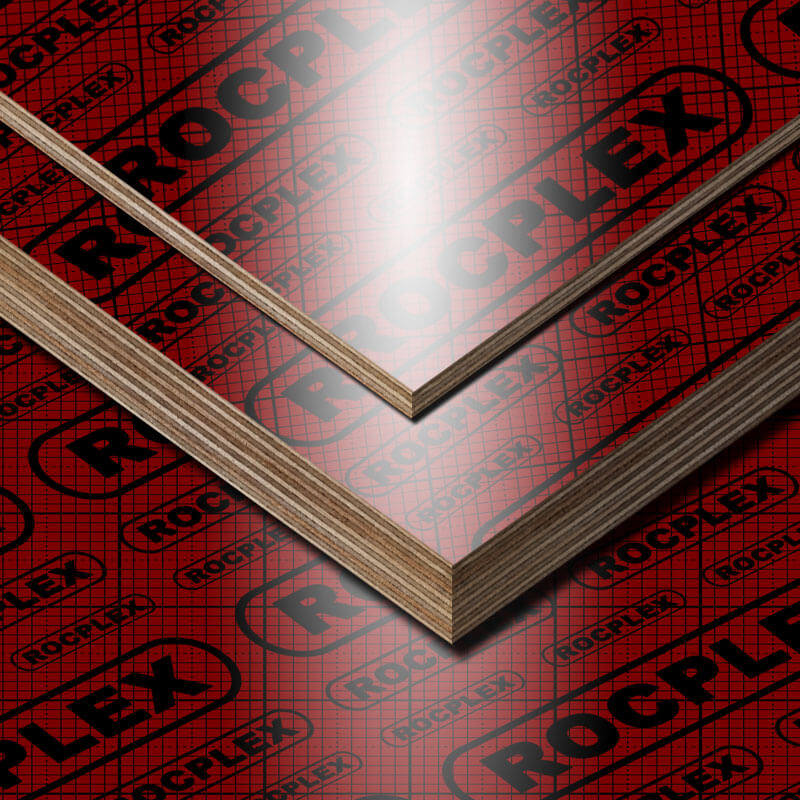

- Superior Strength and Durability: The 21mm thickness of ROCPLEX Shuttering Plywood ensures exceptional strength and load-bearing capacity. It can withstand heavy concrete pours and the pressure exerted during the construction process. Additionally, the plywood is engineered to resist warping, bending, and delamination, providing long-lasting durability.

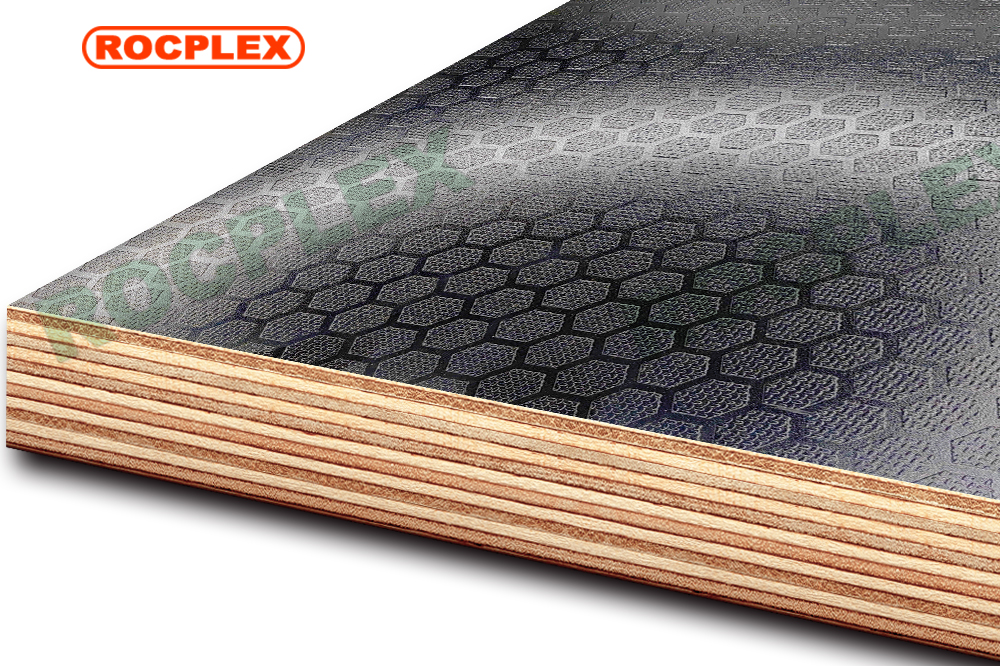

- Phenolic Exterior Surface: The phenolic film coating on the exterior surface of the plywood offers outstanding water resistance and protection against weather elements. It acts as a strong barrier, preventing moisture penetration, ensuring dimensional stability, and prolonging the lifespan of the plywood. The phenolic surface is also highly resistant to wear and tear, making it ideal for rigorous construction applications.

- Easy Form Stripping: The smooth phenolic film surface of ROCPLEX Shuttering Plywood prevents concrete from sticking to the board. This feature facilitates easy form stripping, saving time and effort during the demolding process. It also ensures clean and precise concrete forms with sharp edges and minimal surface imperfections.

- Excellent Surface Finish: The high-quality phenolic film surface delivers exceptional surface finish results. It prevents concrete bleeding and leakage, resulting in smooth and visually appealing finished concrete structures. This feature is particularly important for projects that require a high level of aesthetics.

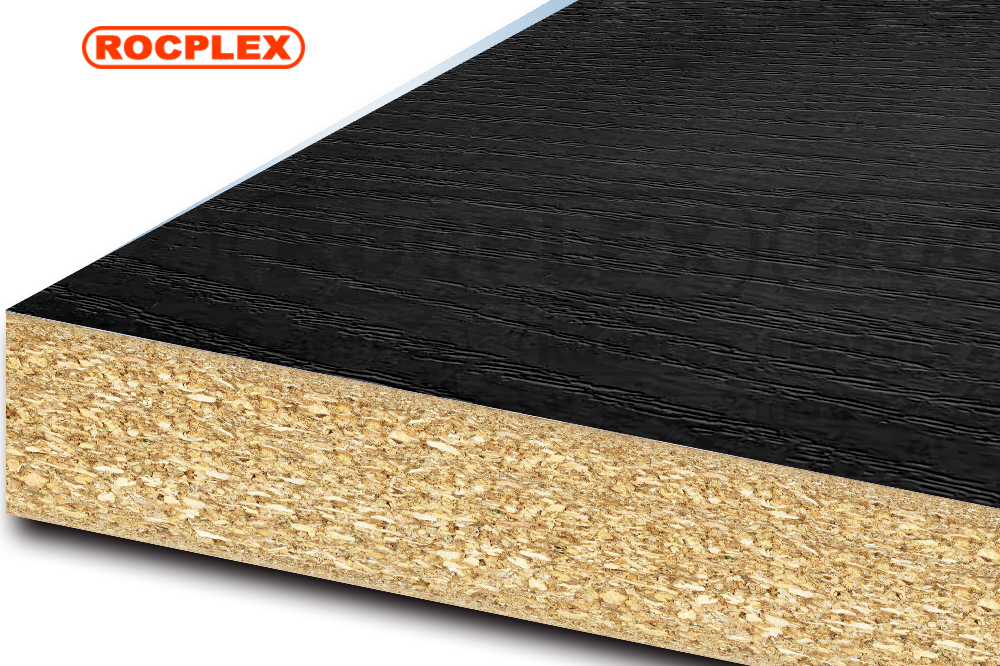

- Sustainable Sourcing: ROCPLEX Shuttering Plywood is manufactured using sustainably sourced timber. The plywood panels consist of multiple layers of hardwood veneers bonded together with exterior-grade adhesive. This ensures that the product meets stringent quality standards while minimizing environmental impact.

|

ROCPLEX 21mm Film faced plywood Save cost |

||

|

|

Be special for phenolic glue and film |

The film-faced plywood can be disassembled and used repeatedly for both faces, saving 25% of the cost. |

|

|

Optimization for the special grade of core |

|

|

|

Be special for adhesive |

|

|

ROCPLEX Film faced plywood Shorten the duration |

||

|

|

Excellent effect of de-molding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

|

|

|

Be easy to incise and blend |

|

|

ROCPLEX Film faced plywood the high-quality casting |

||

|

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

|

|

|

The edges are polished carefully |

|

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding Chinese 21mm film-faced plywood.

Shuttering Plywood 21mm Phenolic Exterior Plywood FAQ

Q: What is the difference between shuttering plywood and regular plywood?

A: Shuttering plywood is specifically designed for use in temporary construction projects such as concrete formwork, while regular plywood is used for a variety of applications, including furniture making, cabinetry, and decorative finishes.

Q: What is the thickness of shuttering plywood?

A: The thickness of shuttering plywood can vary, but 21mm is a common size used in construction projects.

Q: What is phenolic plywood?

A: Phenolic plywood is a type of plywood that is coated with a phenolic resin, which provides additional strength and resistance to moisture, chemicals, and wear.

Q: Is shuttering plywood suitable for exterior use?

A: Yes, shuttering plywood is specifically designed for exterior use and can withstand exposure to the elements.

Q: What are the typical applications of shuttering plywood?

A: Shuttering plywood is commonly used in construction projects such as building foundations, walls, and columns, as well as for creating large concrete slabs and floors.