High-Performance H2S Treated SENSO Framing LVL Beams: 240 x 63mm

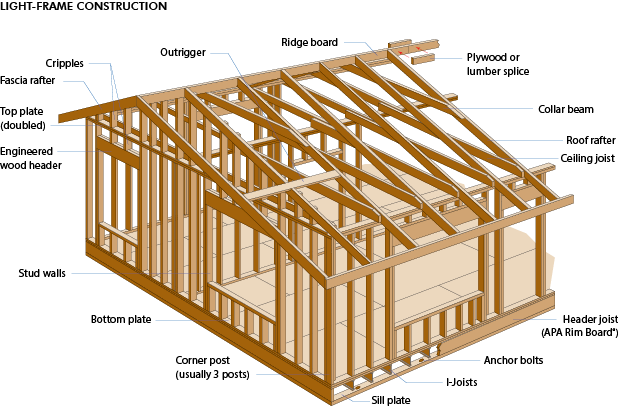

ROCPLEX, Because of their incredible endurance and strength, hardwood timbers were the primary material used to construct bridges, wharves, and industrial structures. These LVL Beams 240 x 63mm structural timbers are also utilized for exterior architectural and landscaping elements such as eye-catching building entry structures, verandahs, pergolas, bench seats, garden stairs, and aesthetically pleasing retaining walls.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

Specifications:

A LVL Beams 240 x 63mm wooden beam is a structural beam composed of single H2S treated piece of wood. The wood is 240 or 63mm, and it can made a connection with nails, screws, or bolts. wood beams for SESNSO framing are frequently used in place of solid wood beams because they are stronger and can hold greater weight. They are also less prone to warping and cracking than solid wood beams. Wood beams may be constructed in a range of forms and sizes to suit the demands of a particular project. They are frequently utilized to construct beams that are longer or stronger than solid wood beams.

LVL E13 beams may also readily bend. To bend a LVL Beams 240 x 63mm wood beam. One method is to use steam. LVL Beams 240 x 63mm It is then twisted into the required form and let to cool and solidify. Heat is yet another method for bending wood.

LVL Beams 240 x 63mm can be twisted into the required form and let to cool and solidify. Pressure is a third method for bending wood. The wood is placed in a mold, and pressure is exerted until the desired shape is achieved.

Advantages:

LVL Beams 240 x 63mm wood beams are a popular building material because they are sturdy, lightweight, and environmentally friendly. Wood beams are very simple to work with and can be tailored to any project. Furthermore, wood beams can aid to increase a building’s energy efficiency.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

6 pallets |

20 CBM |

20000KGS |

19500KGS |

|

40 HQ |

12pallets |

40 CBM |

25000KGS |

24500KGS |

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying LVL and plywood board.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

LVL Beams 240 x 63mm FAQ

Q: What are the advantages of using LVL beams?

A: LVL beams have several advantages over traditional sawn lumber beams. They are stronger, more durable, and more resistant to warping and splitting. They also have greater dimensional stability, meaning they are less likely to change shape or size due to changes in temperature or humidity. LVL beams are also lighter than steel beams, making them easier to handle and transport.

Q: What applications are LVL beams suitable for?

A: LVL beams are commonly used in load-bearing walls, roof beams, and floor joists. They can also be used in a variety of other applications, such as bridge construction, scaffold planking, and furniture manufacturing.

Q: How are LVL beams manufactured?

A: LVL beams are manufactured by layering thin sheets of wood veneers together with adhesives. The veneers are oriented in the same direction, which maximizes strength and stiffness. The layers are then bonded together under heat and pressure, creating a strong and durable beam.

Q: Can LVL beams be cut to size?

A: Yes, LVL beams can be easily cut to size using standard woodworking tools. However, it is important to follow manufacturer guidelines and recommendations to ensure proper cutting and installation.

Q: Are LVL beams environmentally friendly?

A: LVL beams are considered to be an environmentally friendly building material. They are made from a renewable resource (wood), and the manufacturing process generates very little waste. Additionally, LVL beams are often manufactured using adhesives that are low in formaldehyde, reducing their impact on indoor air quality.