Discover the differences between MDF / HDF boards, their various uses, and the benefits they offer. Learn about MDF sheets, hardboard, and other related terms.

MDF (medium density fibreboard) and HDF (high-density fibreboard) are engineered wood products made from wood fibres, resin, and wax. While both types of boards are similar in composition, there are differences in their density and intended use.

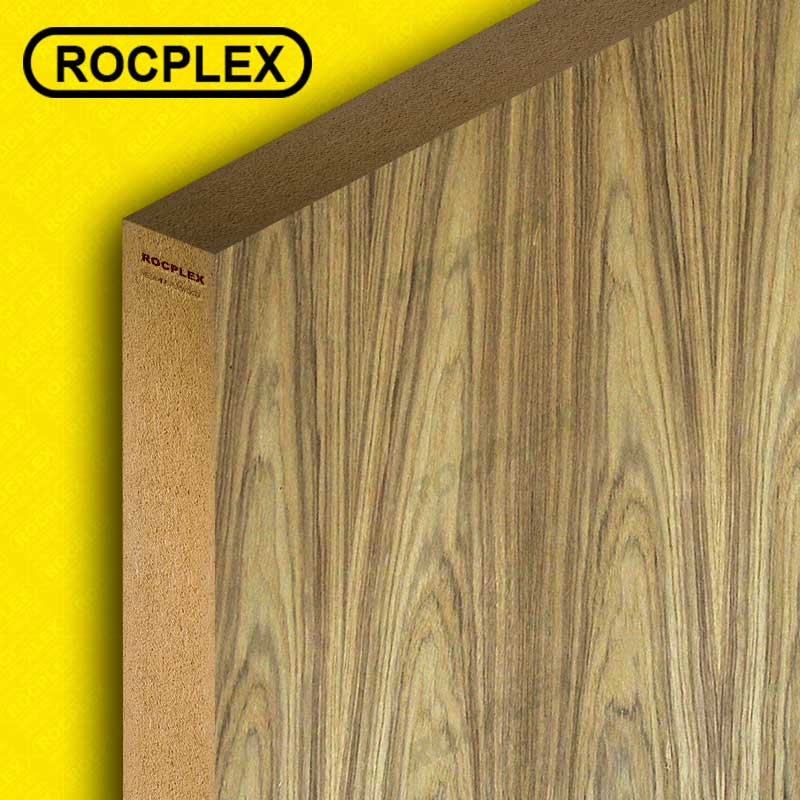

MDF:

- M D F is made from wood fibers and resin, creating a smooth, consistent surface.

- M D F has no grain, knots, or voids, making it ideal for painting and laminating.

- M D F is widely used for furniture, cabinets, moldings, and interior doors.

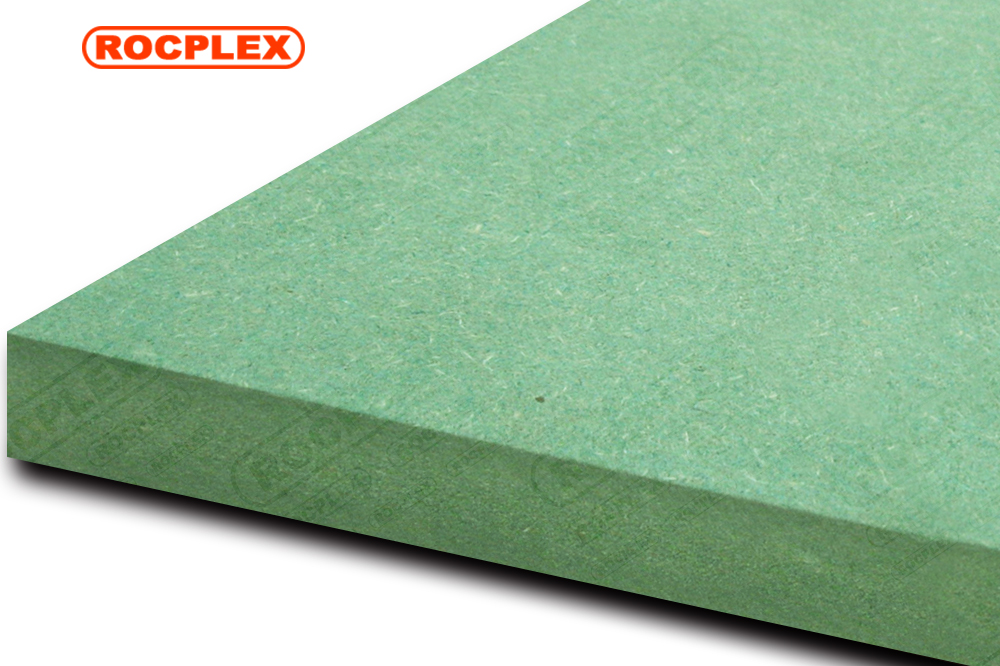

HDF:

- HDF is made from highly compressed wood fibers, resulting in a denser panel.

- HDF has higher bending and tensile strength, making it ideal for flooring and wall paneling.

- HDF is also used for doors, cabinet backs, and decorative accents.

Comparing MDF and HDF:

- M D F is less dense and less strong than HDF, but it’s smoother and easier to shape.

- HDF is more suitable for heavy-duty applications and has better screw holding power.

- Both MDF/HDF board are eco-friendly, as they’re made from recycled wood fibers.

Choosing the Right Panel:

- Consider the intended use and environmental conditions of the project.

- MDF is suitable for interior applications, while HDF is better for flooring and exterior use.

- Choose the appropriate thickness and density for optimal performance.

MDF/HDF are versatile wood-based panels that offer a wide range of applications and benefits. Choosing the right panel for your project depends on its intended use and specific requirements.