Phenolic plywood is a remarkable material widely used in various industrial applications, particularly in the construction of molds. Its exceptional water resistance and durability make it an ideal choice for industrial molds that require high-performance and long-lasting solutions.

In this blog, we will delve into the unique properties of phenolic plywood, explore its benefits, and understand why it is the preferred material for industrial mold construction.

Understanding Phenolic Plywood:

What is Phenolic Plywood?

Phenolic plywood is a type of plywood that is impregnated with phenolic resin, which is known for its excellent waterproofing and bonding properties. The phenolic resin acts as a protective barrier, making the plywood highly resistant to moisture, chemicals, and fungal attacks.

Manufacturing Process

The production of phenolic plywood involves several steps, starting with the selection of high-quality veneers. These veneers are then treated with phenolic resin and subjected to high pressure and temperature to create a strong and durable composite material.

Key Features Of Phenolic Plywood:

The key features of phenolic plywood are its excellent resistance to moisture, chemicals, and fungal attacks. This makes it an ideal material for use in outdoor applications such as decks and patios.

Water Resistance

One of the most significant advantages of phenolic plywood is its exceptional resistance to water. Unlike traditional plywood, phenolic plywood does not swell or warp when exposed to moisture, making it an ideal choice for applications where water resistance is crucial, such as industrial molds used in wet environments.

Durability and Strength

Phenolic plywood is renowned for its superior strength and durability. The combination of high-quality veneers and the bonding properties of phenolic resin results in a plywood material that can withstand heavy loads, repetitive usage, and harsh conditions without compromising its structural integrity.

Benefits Of Phenolic Plywood In Industrial Mold Construction:

Phenolic plywood is ideal for industrial molds. It offers:

Extended Lifespan

Industrial molds are subjected to constant stress and exposure to water, chemicals, and high temperatures. Phenolic plywood’s ability to resist these factors ensures a longer lifespan for the molds, reducing the need for frequent replacements and minimizing production downtime.

Enhanced Surface Finish

Phenolic plywood provides a smooth and consistent surface finish, which is crucial for industrial molds that produce intricate or high-precision components. The material’s stability and resistance to warping ensure that the mold maintains its shape, resulting in precise and consistent product outcomes.

Ease of Machining and Maintenance

Phenolic plywood is relatively easy to machine, allowing for precise cutting and shaping of molds according to specific design requirements. Additionally, the material requires minimal maintenance, making it a cost-effective choice for industrial mold construction.

Applications Of Phenolic Plywood In Industrial Molds:

Phenolic plywood is ideal for the construction of molds that require high precision and strength, such as industrial molds for plastic injection molded components. The material’s stable structure and resistance to warping ensure that the mold maintains its shape during production cycles, resulting in consistent product outcomes.

In addition, phenolic plywood is relatively easy to machine and requires minimal maintenance, making it a cost-effective choice for manufacturing applications.

Concrete and Composite Molds

Phenolic plywood is commonly used in the construction of concrete and composite molds. Its water resistance and durability make it an excellent choice for producing various concrete products, such as precast elements, countertops, and architectural components.

Metal Casting Molds

Industrial molds used for metal casting processes often require high heat resistance and dimensional stability. Phenolic plywood fulfills these requirements, making it suitable for creating molds for casting metals like aluminum, bronze, and iron.

Plastic Injection Molds

Phenolic plywood is also utilized in the production of plastic injection molds. Its excellent dimensional stability and resistance to moisture ensure that the molds can withstand the high pressure and heat involved in the injection molding process, resulting in accurate and defect-free plastic components.

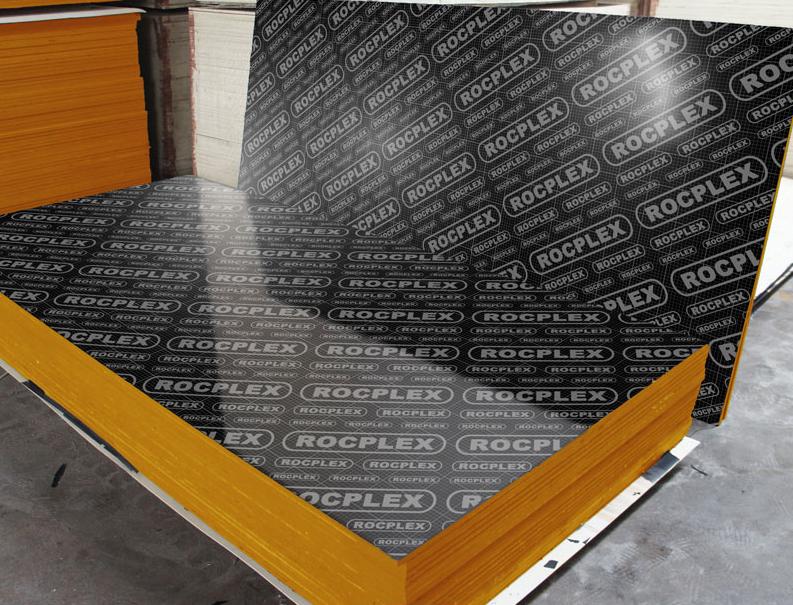

Why Choose ROCPLEX’s Phenolic Plywood?

ROCPLEX’s phenolic plywood provides excellent dimensional stability and resistance to moisture, making it an ideal material for use in the production of molds for metal and plastic casting processes.

In addition, its unique appearance makes it an attractive option for applications where aesthetics are important.

Extensive Productivity and Advanced Machinery:

ROCPLEX boasts high annual productivity of 220,000m3 for all types of plywood and 1,000,000m3 for film-faced plywood. The company is equipped with advanced machines, including Italian IMEAS sanders, Japanese UROKO peeling machines, Veneer Joint Tenderizers, and large dry machines.

This commitment to advanced technology ensures the production and export of the highest quality products, including phenolic plywood, marine plywood, LVL beams, OSB boards, MDF boards, and luxury vinyl flooring.

Customization and OEM Services:

ROCPLEX understands the diverse requirements of the global market and has established partnerships with renowned building material wholesalers. The company offers design and OEM services for its brand plywood and furniture. This customization capability allows for tailored solutions to meet specific needs and ensures customer satisfaction.

Superior Quality Management and Leading Technology:

ROCPLEX prioritizes superior quality management, ensuring that its products meet the highest standards. The company focuses on excellent service and leading technology, and actively leads the market. To provide customers with the highest quality products and services. This commitment to quality ensures that customers receive reliable and durable phenolic plywood.

Final words:

Phenolic plywood stands out as a reliable and durable material for industrial mold construction. Its remarkable water resistance, durability, and ease of machining make it the preferred choice for a wide range of applications.

When it comes to industrial molds, investing in phenolic plywood ensures longevity, high-quality output, and cost-effectiveness in the long run. Whether concrete moulds, metal casting molds or plastic injection moulds. Phenolic plywood has proven to be a valuable asset in industrial manufacturing processes.

Post time: 6 月-22-2023