HDO Plyform

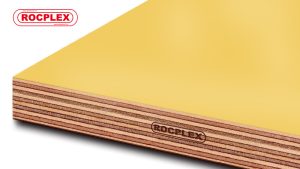

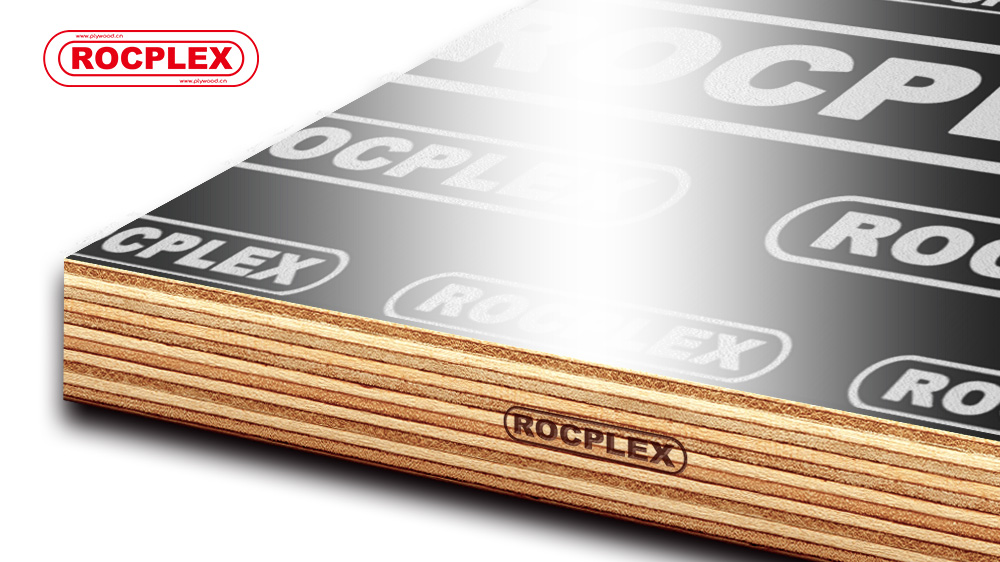

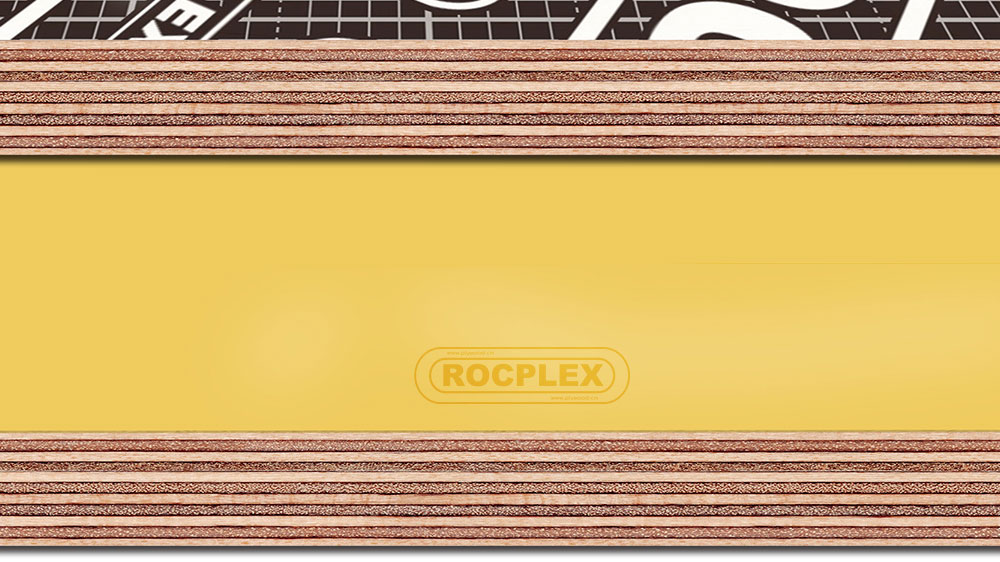

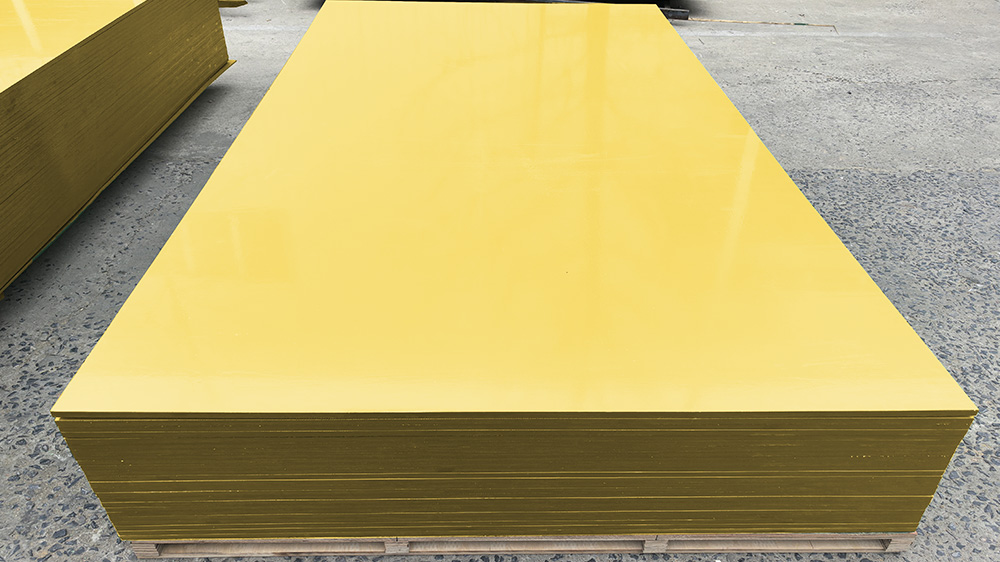

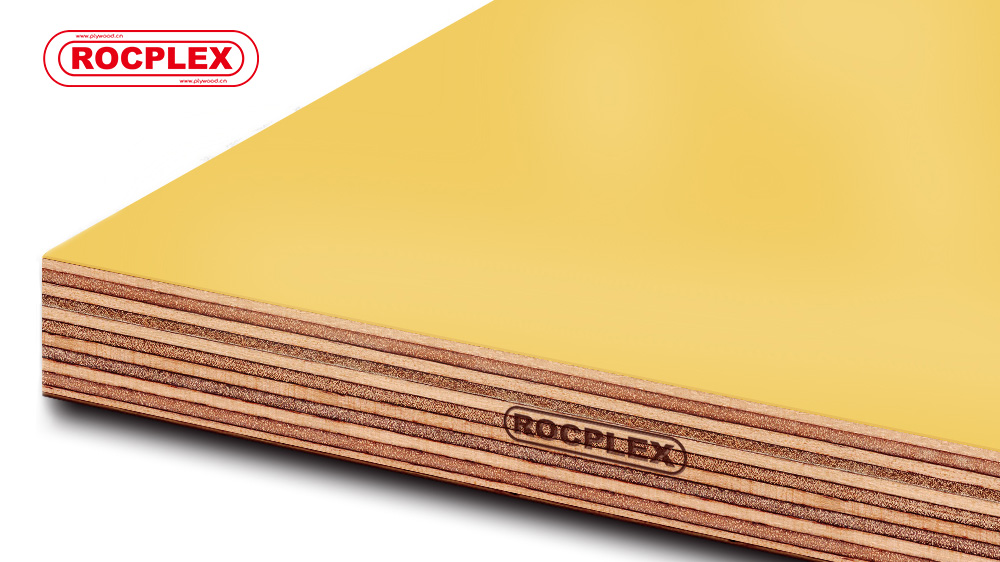

ROCPLEX HDO Plywood Plyform is manufactured to meet the toughest demands of modern concrete formwork systems. It combines a strong core with a durable overlay for consistent site performance. Each panel is bonded with a phenolic resin-treated high-density film that forms a protective, smooth outer surface.

The overlay enhances panel longevity and ensures minimal concrete adhesion. ROCPLEX HDO plywood reduces surface defects and delivers clean demoulding after every use. Its structure resists swelling, splitting, and edge deformation under repeated wet-dry cycles.

Every panel is pressed under high temperature to secure strong adhesion between layers. The bonding method ensures the overlay resists breakdown even under high pressure. ROCPLEX applies advanced control over thickness, moisture, and flatness to maintain accurate dimensions.

Panels are built with FSC and PEFC certified veneers, ensuring environmental responsibility. Each product meets strict compliance standards while maintaining industry-leading performance and finish consistency.

|

||

| Form HDO Plyform |

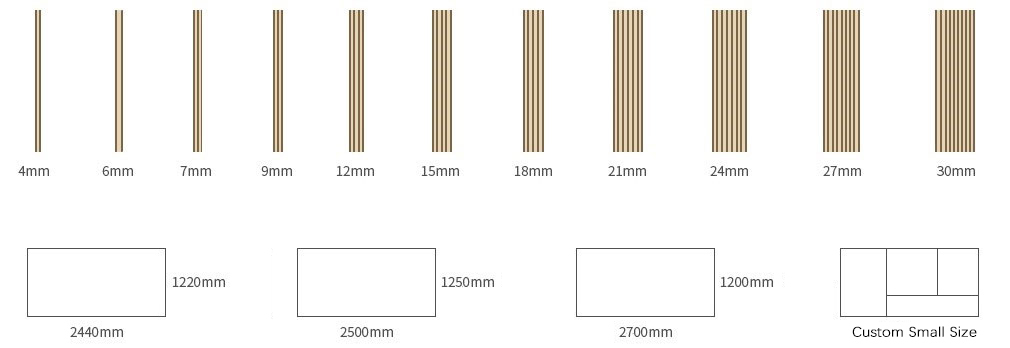

| Thickness (mm) | Length (mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Birch / Hardwood | AA |

| 7 | 2440 | 1220 | Birch / Hardwood | AA |

| 9 | 2440 | 1220 | Birch / Hardwood | AA |

| 12 | 2440 | 1220 | Birch / Hardwood | AA |

| 15 | 2440 | 1220 | Birch / Hardwood | AA |

| 17 | 2440 | 1220 | Birch / Hardwood | AA |

| 18 | 2440 | 1220 | Birch / Hardwood | AA |

| 19 | 2440 | 1220 | Birch / Hardwood | AA |

| 25 | 2440 | 1220 | Birch / Hardwood | AA |

| 28 | 2440 | 1220 | Birch / Hardwood | AA |

■ ROCPLEX HDO plywood is coated with a high-density phenolic film that provides superior surface protection and finish quality.

■ The overlay resists abrasion, alkali reactions, and water absorption, making it ideal for extended reuse.

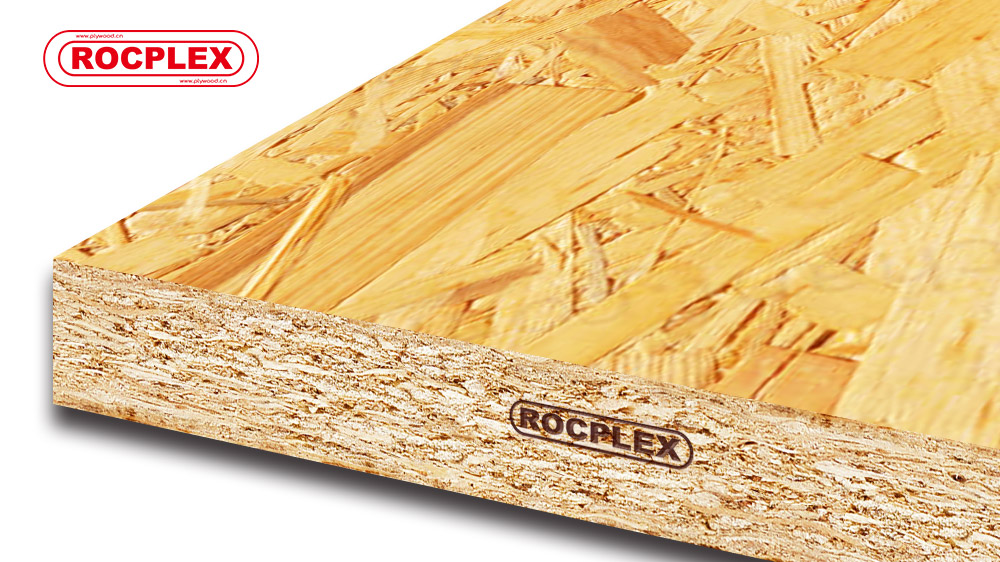

■ Core veneers are selected and calibrated to maintain uniform load-bearing performance across all panels.

■ Each sheet has tight dimensional tolerance, ensuring flush panel joining and accurate form alignment on site.

■ The smooth surface prevents air bubbles and streaks in finished concrete, reducing finishing labor costs.

■ With waterproof bonding, ROCPLEX panels maintain their strength in wet and variable environments.

■ The film coating allows easy stripping and minimal cleaning between pours, saving time and improving efficiency.

■ Each board undergoes thorough quality inspection, including glue strength, moisture level, and visual grading.

■ ROCPLEX uses sustainable forestry resources, aligning with green building practices and environmental certification needs.

ROCPLEX HDO Plyform FAQ

Q: What is ROCPLEX HDO Plyform used for?

A: ROCPLEX HDO Plyform is used in concrete formwork where a smooth, durable finish is required. It supports repeated pours with minimal surface wear.

Q: What does HDO mean in plywood?

A: HDO stands for High Density Overlay. It refers to a resin-treated surface film that provides strength, moisture resistance, and smooth concrete release.

Q: How many times can ROCPLEX HDO panels be reused?

A: With proper handling and cleaning, ROCPLEX HDO Plyform can be reused multiple times, often more than standard formwork plywood.

Q: Is ROCPLEX HDO plywood water-resistant?

A: Yes. The phenolic coating and waterproof glue system provide high resistance to moisture, alkali exposure, and form-release chemicals.

Q: How does HDO compare to MDO plywood?

A: HDO provides a harder, more durable surface than MDO, allowing for more reuses and a smoother concrete finish.