Grid Antislip Plywood

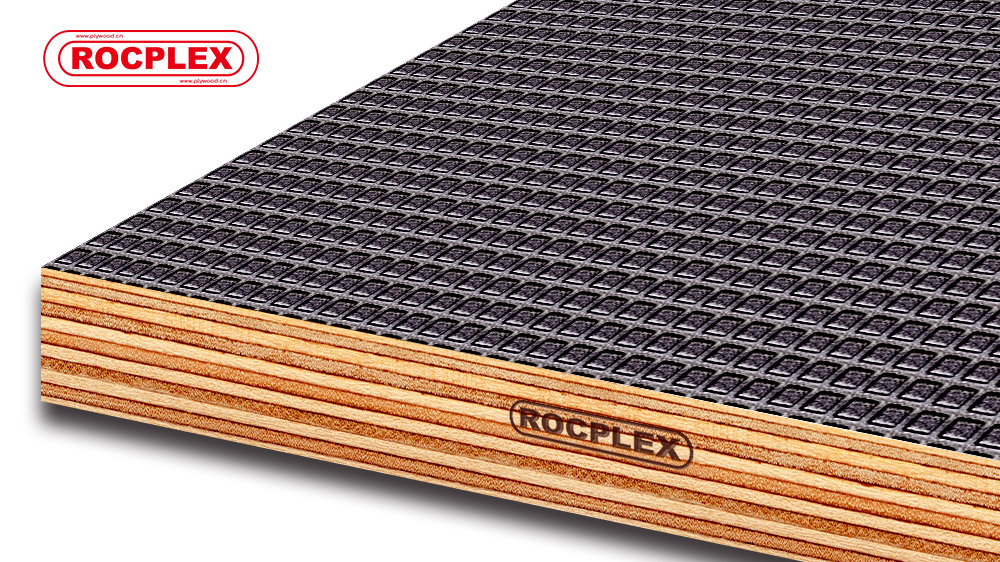

ROCPLEX Grid Antislip Plywood

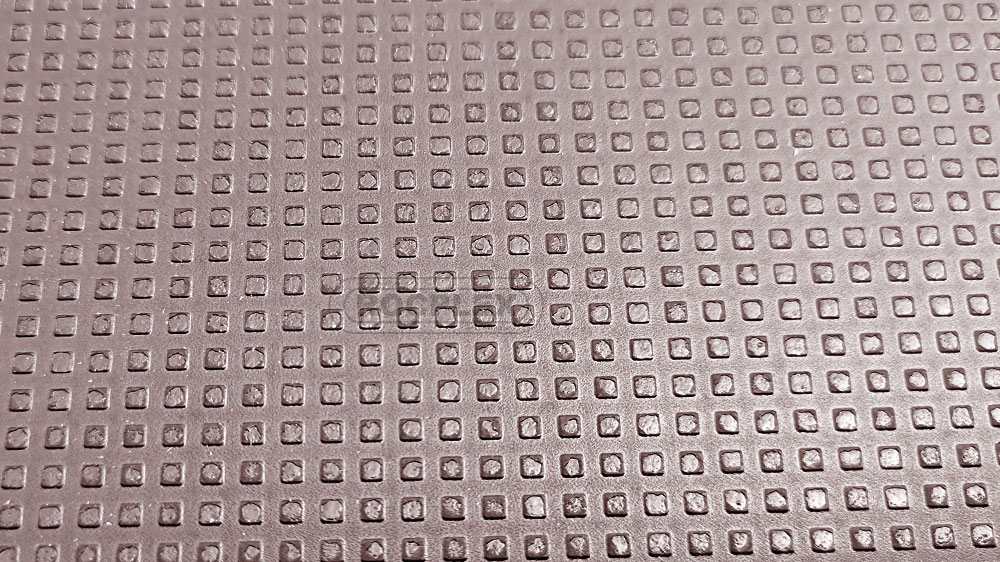

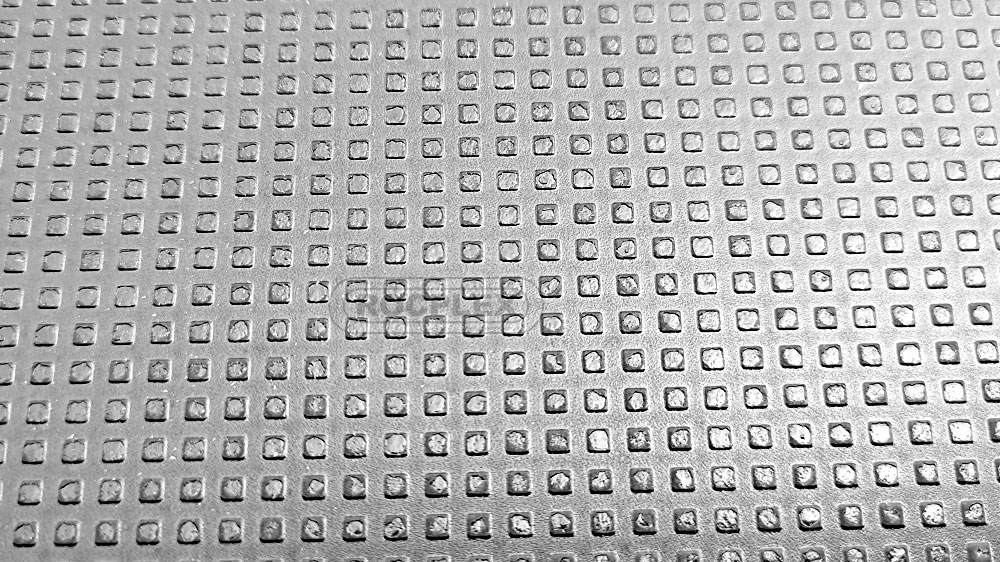

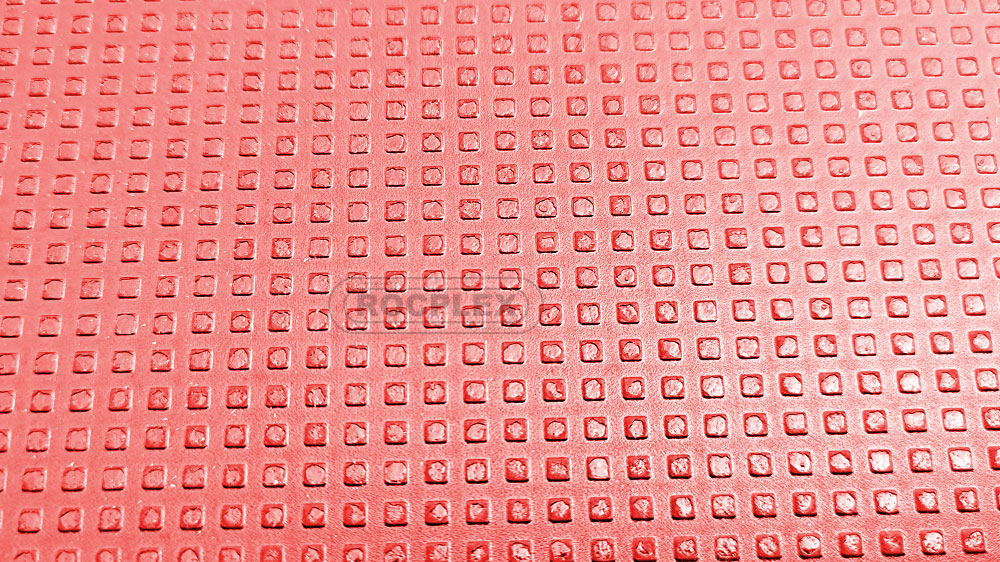

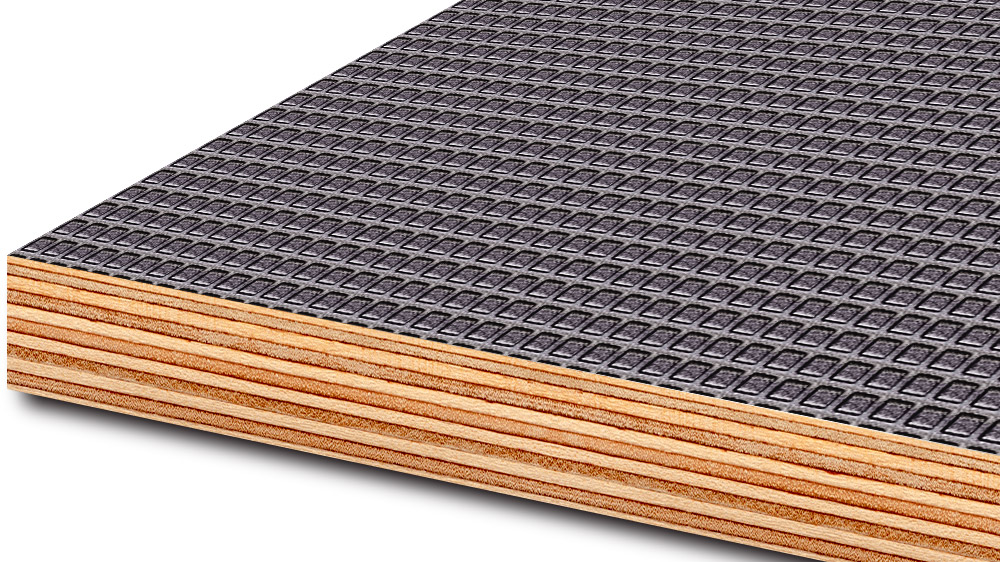

ROCPLEX grid antislip plywood is engineered for safety-critical flooring applications where slip resistance is essential. The top surface is covered with a durable phenolic film featuring a pressed wire-mesh pattern that increases traction, even in wet environments.

Each plywood core is made from selected hardwood veneers bonded with waterproof WBP glue, ensuring exceptional structural stability and weather durability. The reverse side is sealed with a smooth phenolic film to enhance moisture protection and prevent distortion over time.

ROCPLEX grid antislip plywood undergoes strict quality inspection to guarantee consistent thickness, surface bonding, and load performance. The panels are pressed under high pressure and heat, creating a reliable board for repeated use in harsh working conditions.

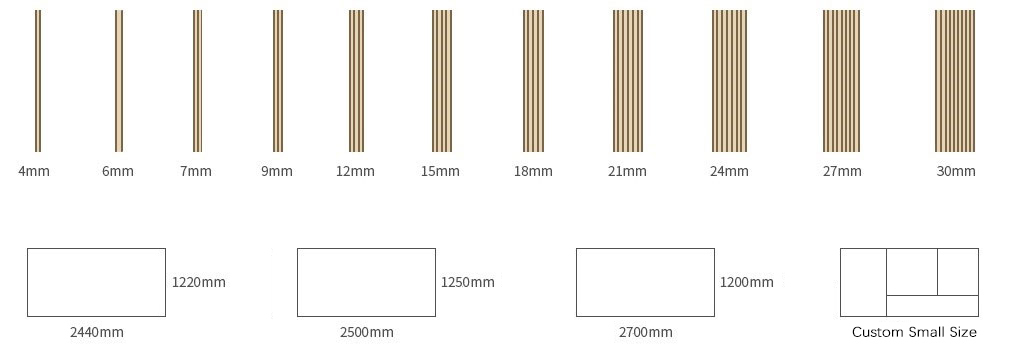

This anti-slip plywood is available in various thicknesses and formats, catering to flooring needs in transport vehicles, container builds, loading platforms, and construction scaffolding.

Standard sizes include 1220mm x 2440mm and 1500mm x 3000mm, with thickness options ranging from 9mm to 28mm.

>>>

ROCPLEX Grid Antislip Plywood Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Hardwood / Birch | AA |

| 7 | 2440 | 1220 | Hardwood / Birch | AA |

| 9 | 2440 | 1220 | Hardwood / Birch | AA |

| 12 | 2440 | 1220 | Hardwood / Birch | AA |

| 15 | 2440 | 1220 | Hardwood / Birch | AA |

| 17 | 2440 | 1220 | Hardwood / Birch | AA |

| 18 | 2440 | 1220 | Hardwood / Birch | AA |

| 19 | 2440 | 1220 | Hardwood / Birch | AA |

| 25 | 2440 | 1220 | Hardwood / Birch | AA |

| 28 | 2440 | 1220 | Hardwood / Birch | AA |

>>>

ROCPLEX Grid Antislip Plywood Regular Optional Colors

>>>

ROCPLEX Grid Antislip Plywood Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | Antislip | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | A Bond | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 630-720 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX Grid Antislip Plywood Features & Benefits

- Excellent Slip Resistance

- The wire mesh surface significantly improves grip, reducing the risk of slips and falls on wet or angled surfaces.

- Phenolic Film Coated

- High-quality phenolic film overlays both sides, with the grid surface on top and smooth film on the reverse.

- Durable Core Structure

- Constructed using full hardwood or high-density poplar core with WBP glue for structural strength and longevity.

- Moisture and Wear Resistant

- Resistant to abrasion, water, and chemicals, making it ideal for outdoor or industrial use under heavy loads.

- Custom Sizes and Thickness Options

- ROCPLEX offers flexibility in dimensions to suit trailer floors, ramps, containers, and construction platforms.

- Environmentally Friendly and Compliant

- Manufactured in compliance with international formaldehyde emission and FSC standards.

>>>

ROCPLEX Grid Antislip Plywood Certified By

|  |  |  |

ROCPLEX grid antislip plywood is widely used in transportation vehicles such as truck trailers and container floors, where slip resistance is critical.

It is a popular choice for construction platforms, scaffold walkways, and loading ramps due to its durable grip surface.

Event staging, temporary walkways, and industrial flooring also benefit from the anti-slip qualities of this mesh-patterned plywood.

With high water resistance and abrasion tolerance, the product is well-suited for high-traffic and outdoor flooring environments.

Upgrade your flooring safety with ROCPLEX grid antislip plywood. Contact ROCPLEX now for sizes, pricing, and global delivery options tailored to your flooring application.

>>>

ROCPLEX Grid Antislip Plywood Plywood FAQ

Q: What is grid antislip plywood?

A: Grid antislip plywood is a film-faced plywood panel with a textured wire mesh surface. It offers increased traction and is designed for flooring in trucks, scaffolds, and industrial platforms.

Q: Can this plywood be used in outdoor or wet environments?

A: Yes. ROCPLEX grid antislip plywood is bonded with WBP glue and sealed with phenolic film, making it ideal for moist and outdoor use.

Q: What are the common applications of this product?

A: It’s widely used in trailer floors, warehouse loading ramps, container flooring, scaffolding, and temporary walkways where slip resistance is crucial.

Q: How long does ROCPLEX grid antislip plywood last?

A: “With proper use, it lasts for many cycles. It’s resistant to water, wear, and chemicals, which extends its lifespan compared to untreated panels.

Q: Can I order customized sizes or branding?

A: Yes. ROCPLEX provides custom thicknesses, dimensions, and logo printing on request for bulk orders.