Introduction to Types of Plywood

Types of plywood remain one of the most searched topics in the building material industry. Contractors, wholesalers, and factories all ask the same question: which plywood is best? The answer depends on the application, budget, and durability requirements.

Plywood is a panel made by gluing thin layers of wood veneer together. The cross-grain construction makes it stronger than solid timber of the same thickness. This is why plywood sheets are used worldwide in construction, interiors, and furniture.

We provide a complete guide on the types of plywood. We also explain how plywood sheets compare with other wood panels such as ply board and wooden board.

Why Buyers Care About Types of Plywood

Global wholesalers often need a reliable supply of plywood. Construction sites look for strength and moisture resistance. Furniture makers want smooth faces and easy machining. Importers need stable supply chains and consistent grading.

The main customer pain points include:

– Unclear grading systems across markets.

– Variation in thickness and density.

– Moisture swelling in low-quality plywood sheets.

– Price competition against alternative wood panels.

As professional suppliers, we solve these issues with strict production control. Our plywood sheets, wood panels, and timber products meet global standards for durability and safety.

Major Types of Plywood for Construction

Structural Plywood

Structural plywood is designed to carry load. Builders use it for flooring, roofing, and wall bracing. Its cross-laminated design provides excellent strength.

Marine Plywood

Marine plywood resists water and humidity. It is ideal for boat building, bathrooms, and exterior use. Buyers often prefer marine grade over standard wooden board when moisture is a concern.

Film Faced Plywood

Film faced plywood has a resin-coated surface. It is used for concrete formwork. Contractors select it because it can be reused many times.

Hardwood Plywood

Hardwood plywood is made with dense veneers such as birch or eucalyptus. It is popular in furniture and cabinet production.

Softwood Plywood

Softwood plywood is often made from pine or fir. It is lighter and used in general construction. Ply board of this type offers a cost-effective option.

Interior Types of Plywood

Decorative Plywood

Decorative plywood uses fancy veneers. It is chosen for panels, doors, and interior design. Wooden board with veneer faces creates a high-end look.

Flexible Plywood

Flexible plywood bends easily without breaking. It is used in curved furniture and special designs.

Fire Retardant Plywood

Fire retardant plywood slows the spread of flames. Many commercial projects require it to meet building codes.

Comparing Plywood with Other Wood Panels

Some buyers confuse plywood with wood board or particle board. While all are wood panels, the performance differs.

– Plywood sheets: Strong, stable, and versatile.

– Wood board: Can mean solid timber or engineered board.

– Ply board: Another term for plywood in some markets.

– Wood panels: Includes MDF, OSB, and plywood.

Each option has its place. But types of plywood are often chosen when durability and strength are critical.

Types of Plywood for Furniture Applications

Commercial Plywood

Commercial plywood is the standard option for furniture. It balances price and quality. Many wholesalers request this grade for tables, shelves, and cabinets.

Veneer Plywood

Veneer plywood has a decorative surface layer. Factories use it for visible furniture parts. It gives the appearance of solid timber while keeping costs lower.

Moisture Resistant Plywood

Moisture resistant plywood is designed for kitchens and bathrooms. Compared with standard wooden board, it resists swelling.

Laminated Plywood

Laminated plywood has a surface layer of melamine or laminate sheet. This makes it more durable against scratches.

Global Standards and Thickness Options

Buyers often ask what sizes and standards are available.

– Thickness: Commonly ranges from 3mm to 25mm.

– Sizes: The global standard is 1220mm × 2440mm. Custom sizes are also possible.

– Standards:

– BS1088 for marine plywood.

– EN 636 for structural plywood.

– AS/NZS 2269 for construction in Australia.

Meeting these standards ensures trust in global trade. Suppliers like us follow strict grading systems to provide consistent plywood sheets and wood panels.

Cost Factors for Wholesalers and Buyers

The cost of plywood depends on several factors:

1. Wood Species: Hardwood plywood is more expensive than softwood plywood.

2. Glue Quality: Water-resistant and phenolic adhesives increase durability.

3. Surface Finish: Laminated and decorative plywood command higher prices.

4. Market Supply: Timber supply, shipping rates, and demand affect final cost.

Wholesalers aim to balance quality with price. Reliable suppliers provide stable costs and avoid hidden issues like poor core gaps or uneven layers.

Practical Tips When Choosing Types of Plywood

– For heavy construction: Choose structural or film faced plywood.

– For wet areas: Use marine or moisture resistant plywood.

– For furniture: Select commercial plywood or veneer plywood.

– For decorative use: Flexible or fancy plywood adds style.

By matching the type of plywood to the project, buyers reduce waste and increase satisfaction.

FAQs About Types of Plywood

What is the strongest type of plywood?

Marine plywood and structural plywood are the strongest. They are built to handle load and resist water damage.

Which type of plywood is best for furniture?

Commercial plywood and veneer plywood are best for furniture. They are cost-effective and easy to work with.

How long does plywood last?

With proper storage and installation, plywood sheets can last for decades. Marine plywood in particular has excellent durability.

What is the cheapest type of plywood?

Softwood plywood is usually the cheapest. It is widely used for general construction and packing.

Is plywood better than solid wood?

Plywood resists warping better than solid timber. It is more stable and affordable, making it ideal for large panels.

How We Support Global Buyers

As manufacturers and wholesalers, we understand buyer concerns. We focus on:

– Consistent thickness: Every plywood sheet matches specification.

– Moisture control: Proper drying prevents swelling.

– Surface quality: Smooth faces for easy lamination.

– Global logistics: Timely shipments to construction sites and factories.

We supply plywood, timber, and wood panels that match international standards. Our solutions help importers build long-term trust with their own clients.

Types of Plywood

Understanding types of plywood makes global trade easier. Each type serves a different role, from construction to furniture. Wholesalers, builders, and factories save time and cost by selecting the right grade.

With our professional production experience, we deliver plywood sheets, ply board, and wooden board that meet your project needs. Strong partnerships start with reliable supply, and our commitment ensures your business success.

BS1088 Certified Marine Plywood

ROCPLEX 18mm Marine Plywood sheets with waterproof WBP bonding and smooth hardwood veneers provide high strength, moisture resistance, and long-term durability, ideal for boat building, dock construction, wet-area cabinetry, and exterior marine applications.

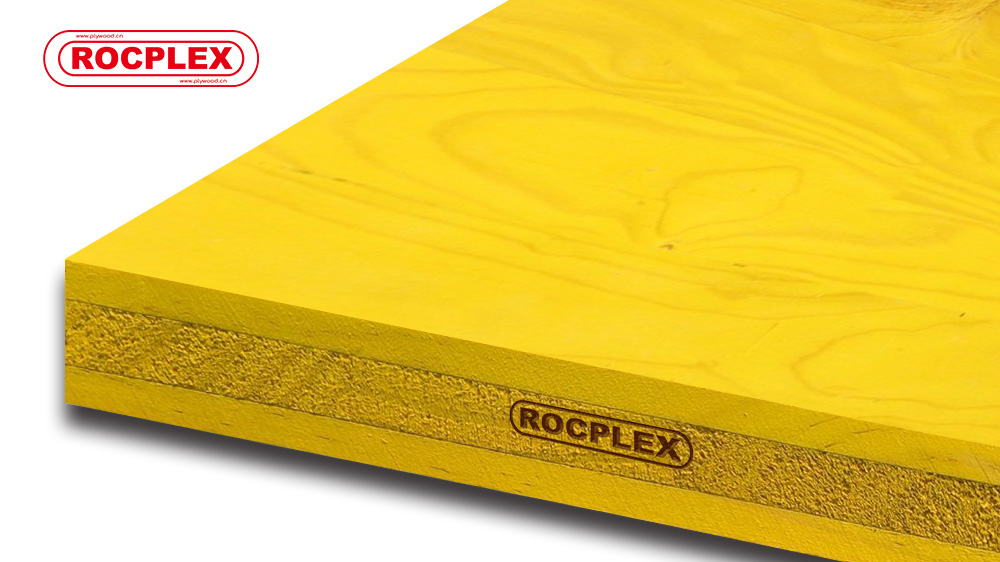

Yellow Formwork Panel

The Yellow Formwork Panel from ROCPLEX is designed for high durability and superior performance in concrete formwork applications. These panels are ideal for ensuring smooth, consistent results in construction projects. With their robust construction and quality materials, ROCPLEX Yellow Formwork Panels are the go-to choice for professionals seeking reliability and efficiency.

PP Plastic Plywood

Plastic Plywood by ROCPLEX is designed for high durability and waterproof performance, perfect for various construction applications. This innovative plywood is coated with a plastic layer that enhances its strength and longevity, making it a top choice for builders.

Post time: Sep-22-2025