Plywood prices basics for fast planning

plywood prices Budgets need facts and flow.

Prices sit at the center of both.

Price is not one line.

It is many choices stacked together.

Core, face, glue, size, and lane all matter.

Season and port rules matter as well.

ROCPLEX links each lever to a clear gain.

Your quotes match the job, not a guess.

What shapes prices at the mill

Logs set the first price band.

Species shift yield and veneer count.

Bigger logs lift recovery and cut breaks.

Drying adds time, heat, and space.

Tight kilns lower field claims.

Press cycles set bond strength and line speed.

More plies raise glue and sanding time.

Every step shows up in your bill.

Plywood sheets and size strategy

Standard 1220 × 2440 plywood suits most lines.

Metric 1250 × 2500 plywood suits many nests.

Cut-to-size raises unit cost a little.

It drops trim and site labor a lot.

That swap often lowers final spend.

ROCPLEX trims square and sands fine.

Edges stay clean for fast installs.

Grade choices that protect margin

Faces drive looks and labor.

B or BB faces suit paint and clear coats.

CP or C serves hidden areas and backs.

Pick the lightest face that still meets the look.

You reduce waste without risk.

ROCPLEX sends face photos with each bid.

Approvals move fast and stay calm.

Core maps that balance price and strength

Hardwood cores hold screws and span well.

They cost more and weigh more.

Poplar saves weight and freight spend.

Combo cores split the difference wisely.

CNC shops like dense, even cores.

Install crews like lighter lifts.

We align core maps with end use.

Glue classes and service life

Exterior bonds resist wet cycles and heat.

They need more energy and longer presses.

Interior bonds suit calm, dry rooms.

They sand fast and cost less.

Film faces add release for formwork.

HPL skins add wear strength for shops.

Pick the lightest stack that still works.

You protect budgets and timelines.

Plywood prices beyond the factory gate

Boxes move through real lanes.

Ocean rates rise and fall with season.

Trucking and depots add local steps.

Free time rules change by port and union.

Paperwork can stall cargo and add fees.

We plan routes that fit your mix.

Your extras drop and flow improves.

Packaging that saves money down the line

Damage costs more than better wrap.

Edge paint blocks moisture wicking.

Corner guards prevent clamp crush.

Top sheets stop strap scuffs on faces.

Barcodes speed checks and claims.

Lift marks prevent fork strikes.

Small steps stop big yard losses.

Plywood prices vs other panel options

MDF paints smooth yet dislikes water.

It can sag under heavy spans.

OSB holds nails and trims budgets.

Its chip look reads through thin skins.

Quality wood panels bridge both ends.

They span better and handle damp sites.

Choose by load, look, and site risk.

We help with quick comparison charts.

Why timing changes plywood prices

Logs follow seasons and road bans.

Rain slows harvests and veneer flow.

Holidays cut port labor and space.

Demand spikes shift quote windows.

Book early for steady lanes and rates.

Split loads when risk runs high.

ROCPLEX warns early and adjusts plans.

Levers for wholesalers

Stock the sizes buyers cut most.

Fewer trims reduce calls and claims.

Bundle a clean grade ladder by use.

Offer face upgrades on fast movers.

Use combo cores for light duty parts.

Hold film-faced options for form crews.

These moves lift margin without noise.

Ply board levers for factories

Map nests to sheet sizes first.

Match kerf loss to blade sets.

Use thinner faces on hidden sides.

Standardize thickness bands per line.

Reduce sand passes with steady feeds.

Pick low-void cores for hinge zones.

Hours saved beat tiny unit cuts.

Total cost of ownership in one view

Unit price is step one only.

Counting waste matters more.

Counting rework matters most.

Freight and storage add real money.

Claims drain time and brand trust.

We track each cost in one sheet.

You see where cash escapes.

Then we close those gaps together.

Plywood prices myths we hear often

Cheapest wins profit every time.

False. Returns erase small wins fast.

Exterior glue solves every issue.

No. Bad storage ruins any stack.

More plies always beat fewer.

Design and load decide that call.

Film faces only suit concrete.

Shops use them for jigs every day.

People also ask — clear answers

Why do plywood prices spike?

Supply and freight shocks align.

Logs tighten. Ports clog. Demand surges.

Smart buyers split routes and stage loads.

We keep those playbooks ready.

Which panel works best for furniture?

Stable cores and good faces win.

B or BB finish clean and true.

Baltic-style stacks hold screws well.

Pick thickness by span and hardware.

How can I estimate panels for a job?

Start with net area first.

Add 10–15% for complex nests.

Use smart plywood sheets to cut waste.

ROCPLEX can simulate nests on request.

How do I cut shipping costs?

Load high CBM per box.

Mix sizes for tight stacks and balance.

Pick near ports when inland legs run long.

Avoid idle time with firm slots.

Is marine plywood always required outdoors?

No. It suits long, wet cycles.

Many installs live indoors.

Exterior bonds and sealed edges may suffice.

Match duty to exposure and time.

Compliance that protects bids

Certs can add fees.

They also open tenders and doors.

Chain-of-custody protects brands and lanes.

Emission classes matter in closed rooms.

Share rules early and avoid stress.

We align runs and hold the reports.

ROCPLEX service that guards your margin

We quote with photos and grade notes.

Show core maps and glue stacks.

Send pack lists with weights and labels.

Confirm ETDs and vessel shifts early.

ROCPLEX stand behind each shipped load.

Claims move fast with full files.

Your phone stays quiet.

Your crews stay focused.

Plywood prices playbook you can use today

Pick the right face for the look.

Pick the lightest core that meets span.

Choose glue by duty and climate.

Trim sizes to reduce site cuts.

Plan storage with dry air and level racks.

Seal cuts as you go at site.

Load boxes for balance and density.

Keep one spare size for swaps.

These steps save money on every job.

Case notes from active lanes

A cabinet line in Brisbane cut trim by 9%.

They switched to tighter sizes and cleaner cores.

Changeover time fell with fewer blade swaps.

A form crew in Auckland cut claims to near zero.

Film faces and sealed edges did the work.

Loads arrived with lift marks and guards.

Pours finished on time despite rain.

Plywood prices forecast habits that help

Watch rates three weeks ahead.

Check port free time before you book.

Hold two routes when space gets tight.

Group POs by grade and thickness.

Share your calendar with our planners.

We block line time and lock slots.

How ROCPLEX keeps quotes steady

We pool veneer across sister lines.

Reserve cycles for repeat buyers.

Plan boxes around lane rules.

Choose mills close to ports when possible.

ROCPLEX send photos as each batch runs.

You see progress and plan with confidence.

Finance and ops FAQ

Can you price in multiple currencies?

Yes. We quote in USD and local pairs.

We also map bank days to sailing windows.

Do you support split shipments?

Yes. We can stage releases by week.

That lowers yard pressure and cash peaks.

Can you label to our SKU rules?

Yes. We print barcodes and pack IDs.

Your WMS scans faster with fewer errors.

Do you supply test data?

Yes. We share bond, MOR, and moisture.

Pull samples travel with first runs.

Plywood prices summary for quick decisions

Start with face and core.

Match glue to real duty.

Trim size to your nests.

Plan lanes with port rules in mind.

Protect packs with smart wrap.

Track total cost, not just unit price.

ROCPLEX guides each step with care.

You gain steady margins and calm jobs.

Why ROCPLEX ply board wins repeat orders

We mix mill craft with trade sense.

Speak plain and act fast.

Protect your time with good prep.

ROCPLEX protect your margin with lean plans.

That is our promise to every buyer.

100% Full Birch Plywood

ROCPLEX Full Birch Plywood is crafted using 100% high-grade birch veneers. This plywood features uniform density, smooth surfaces, and strong core bonding. The material is ideal for demanding uses such as cabinetry, interior fittings, and precision machining. Full Birch Plywood from ROCPLEX is known for its stability and screw-holding strength. It provides consistency across sheets and performs well under mechanical stress. ROCPLEX ensures reliable supply and consistent product quality across markets.

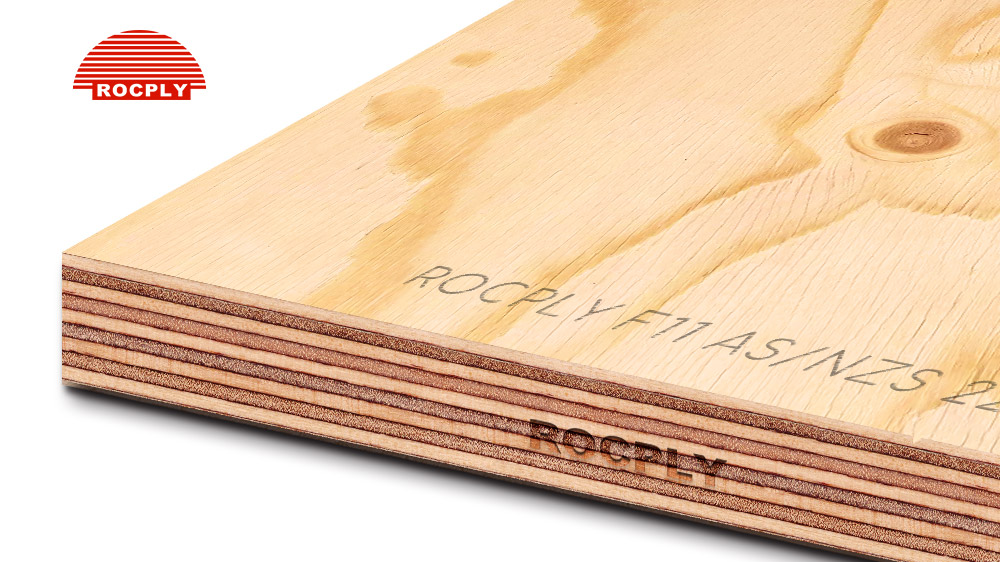

ROCPLY Structural Plywood

ROCPLY Structural Plywood panels with cross-laminated veneers and waterproof bonding meet international structural standards, providing high stiffness, load-bearing capacity, moisture resistance, dimensional stability, and impact durability—perfect for load-bearing floors, walls, roofs, framing, formwork, crates, pallets, and structural construction applications.

Post time: Sep-29-2025