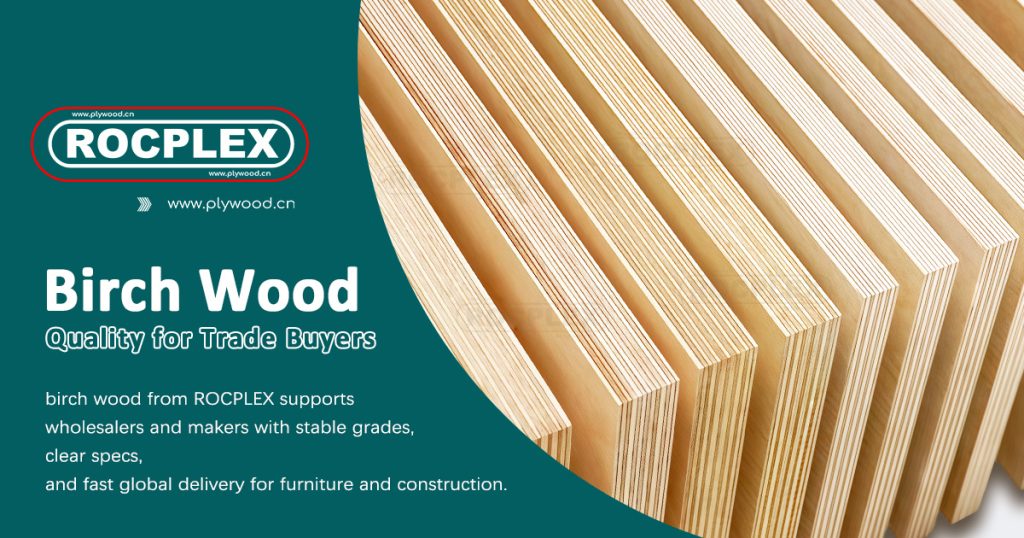

Birch wood sets a calm buying standard

Your margins are tight. Your time is tighter. You need panels and lumber that work right away. Our birch wood mills and export team build for that need. ROCPLEX stands beside trade buyers who want steady quality and simple service.

We align specs with end use and timeline. We mark birch wood packs for fast ID and safe lifts. Your crew unloads, scans, and moves on. Lines keep running. Jobs stay on plan.

What buyers mean by “birch wood grade”

Grades guide price, yield, and finish. We keep grades clean and honest. B/BB faces suit paint or clear coat. CP and C faces suit hidden work. Veneer tightness and patch style stay consistent by batch.

We share grade photos in each quote. Your team knows what arrives. Your clients see the same look across projects.

Birch wood vs birch plywood: a quick map

Solid birch suits frames, rails, and turned parts. birch plywood suits boxes, backs, and jigs. Both options share a fine texture and light tone that takes stain well. You choose by span, screw hold, and finish goal. We cut confusion with clear spec sheets and sample sets.

When you need precision, choose Baltic birch plywood. It uses thin birch plies, more layers, and no softwood fillers. That build raises stiffness and keeps sheets stable.

Baltic birch plywood for precision work

Cabinet shops love tight cores. CNC routers love even density. Baltic birch delivers both with minimal voids. That helps small parts hold detail and edges stay crisp after routing. Many sheets come in 5×5 sizes for Euro cabinet lines and jig work.

Thin Baltic birch can cup when very wide and thin. That is a size effect, not a quality flaw. Plan storage and weights with that in mind.

Core options that fit tasks

Pick dense hardwood cores for span and screw pull. Pick lighter cores when weight matters. For laminates, ask for low-void builds. For clear coats, ask for tight, even faces. We match cores to tools and end use.

We also run birch veneer on combo cores when price and weight need balance. Your rep will map choices to tasks and lanes.

Glue lines and moisture control

Glue choice sets duty. Use exterior bonds for wet cycles and site stress. Use interior bonds for dry fit outs. We test glue lines, heat, and pressure. We track moisture by batch and log records.

Cut edges need sealing on site. That small step protects faces and saves rework. We include a field card with each load to remind crews.

Birch wood uses across industries

Shops use it for cabinets, drawers, shelves, and fixtures. Builders use it for sub-frames, form skins, and stair parts. Makers use it for jigs, crates, and shop furniture. The wood machines well and holds detail. It stains evenly with the right prep. Many sources list furniture, cabinetry, and interior trim as common uses.

Strength and hardness in plain words

Birch sits in the hardwood group. Its hardness varies by species, yet sits near oak and beech levels. Silver birch runs around 1,210 lbf on the Janka scale. Paper birch runs lower. Downy birch sits in the same band. These figures explain its strong wear profile in busy spaces.

Finish, veneer, and color

Faces look light and even. Grain is fine and smooth. That helps paint lay flat and stain read true. Yellow birch shows a gentle curl at times. Plan face selection by target look and patch rules.

For high-wear skins, use film or HPL over birch plywood. That stack resists scuffs and cleans fast. It suits retail, labs, and busy workshops.

Sizing, cutting, and nesting

We stock common sizes for fast turns. 1220×2440 fits most lines. 1250×2500 fits Euro rigs and many CNC nests. We trim true and sand fine. Your bits last longer. Your edges need less touch up.

For complex nests, we pre-optimize cuts. That reduces waste and saves time. Share DXF packs and we will align.

Packing that survives long trips

We build packs that take hits. Wrap tight. Add corner guards and cap sheets. Mark lift points and center balance. And paint edges to block moisture wicks. Door airbags and tight straps reduce shift in transit.

Each pack carries barcodes and gross weight. Teams unload safe and fast. Claims drop to near zero.

Birch wood Certifications and traceability

Your bids need proof. We log batches with press codes and veneer lots. Align runs to market marks on request. And share test data and photos. Your audit folder stays ready.

We also maintain chain-of-custody lines. Ask your rep for current document sets and renewal dates.

FAQs buyers ask about birch wood

Is it a hardwood?

Yes. Birch belongs to the hardwood group and shows fine, diffuse pores. That trait supports smooth finishes and clean machining.

Is it strong enough for cabinets?

Yes. Pick the right species and grade. Use Baltic birch plywood for high loads and tight tolerances. Its many thin plies add stiffness and reduce voids.

Is it water resistant?

The wood itself is not rot-resistant. Choose the right glue and seal edges. Use film faces or HPL in wet zones. Good storage and site sealing matter most.

How does it compare with maple or pine?

Birch is harder than most pines and close to maple on many tasks. It remains easy to machine and finish. Pick species and grade to match load and budget.

Birch wood Pricing and margin protection

You feel pressure from freight and fiber costs. We protect margin by cutting waste. Raise CBM per box with smart sizes. Tune layups for strength with less weight where safe. We quote clean. No hidden fees. You see spec, yield, and pack plan upfront.

When lanes shift, we split routes and balance time and cost. We share rate moves early. Your team can plan cash and loads with less stress.

Logistics and containers

We book early and watch cutoffs. Place heavy packs low and near doors for balance. And add airbags. We track free time and port rules by lane. Updates arrive in plain words. Your crews waste fewer hours at the yard.

Mixed loads help small POs. We group by size and end use. You receive stock that flows straight to lines.

Sustainability that helps bids

We source from known regions with legal harvests. We cut waste in layup and trim. Offcuts go to energy or small parts where possible. Tight packs reduce fuel per CBM. You can show real steps, not vague claims.

Why ROCPLEX birch wood wins repeat orders

We blend mill skill with a trade mindset. We keep promises and share data. Your clients see steady looks and fewer defects. You will claims drop. And Your brand wins trust and time.

We also help with labels, spec sheets, and field cards. We join key calls and support tenders with facts that matter.

Quick start for new partners

Share lanes, targets, and end uses. Align grades and glue lines. Approve pack plans. Book slots. Lock routes. Receive clean goods. That is the flow. No fluff.

Case notes from the field

A cabinet shop in Perth needed tight cores for CNC work. We sent dense birch plywood with fine sand. Bits stayed sharp. Edges looked clean. Output rose without extra hours.

A fit-out team in Auckland faced damp weeks. We shipped film-faced birch panels with sealed edges. Faces released fast. Schedules held. Crews finished on time.

Birch wood technical specs that matter

Moisture content drives stability. We target 8–12% at ship time. Your local climate may differ. Plan short acclimation on site.

Thickness tolerances affect fit and yield. We hold tight bands across all sizes. Edges stay square after trimming and sanding.

Face grades shape looks and price. We align patch style, color tone, and veneer tightness by batch. Photos travel with quotes.

Formaldehyde levels follow your market rules. Ask for E1 or lower when needed. We certify lots and keep reports ready.

Panel density links to screw pull. Dense cores hold fasteners well. Share pull targets and we will match.

Machining tips for clean results

Use sharp carbide blades. Set a fine tooth count for crisp edges.

Feed steady. Avoid heat build-up on long rips.

Back up thin parts near exits. Tear-out falls fast with that step.

Run climb cuts on tricky curves. Keep the pass light.

Drill with brad points for clean holes. Clear chips often.

Sand with a clear grit path. Step up in small moves. Do not skip grits.

Seal edges early if the shop air swings. That habit saves touch-ups.

Finishing and color control

This species takes stain well. Test first on offcuts.

Raise the grain before top coats. Wipe, dry, and sand again.

Use a clear sealer on light looks. Add toner for warm tones.

Pick waterborne coats for low odor lines. Pick catalyzed coats for hard wear.

Watch end grain. It drinks more. Seal or size those areas first.

Keep lighting constant in spray rooms. Color shifts hide in mixed bulbs.

birch wood storage and site prep

Stack flat on level dunnage. Space sticks evenly.

Cover tops, not sides. Let air move around each pack.

Keep stacks off cold floors. Avoid direct sun and wet drafts.

Acclimate sheets before cutting. One or two days often works.

Seal fresh cuts on site. That small step blocks edge wicking.

Quality checks you can run in minutes

Sight the face across light. Look for waves or ripples.

Tap sheet centers. A dull note may hint at voids.

Measure thickness in four corners. Log readings by pack.

Drive a sample screw near edges. Feel for solid bite.

Cut a small strip and bend. A clean bond resists early split.

Spec recipes for common jobs

Cabinets and drawers: 12–18 mm panels, fine sand, tight faces.

Shelves and fixtures: 18 mm or 21 mm panels, dense cores.

Shop jigs and nests: Baltic birch plywood, even plies, low voids.

Form skins and site rigs: film-faced faces, sealed edges, exterior bonds.

Drawer bottoms and backs: 6–9 mm sheets, light yet stiff.

Speaker boxes and cases: 12–15 mm panels, strong glue lines.

Birch plywood and veneer options

birch plywood suits flat parts that need stability. Ask for low-void cores.

Baltic birch plywood brings many thin plies and tight edges. It shines under CNC.

birch veneer upgrades faces for clear coats. We match tone across packs.

birch plywood sheets come in standard and Euro sizes. We trim true to spec.

For lighter builds, mix birch veneer with combo cores. Balance looks and weight.

Joinery playbook for strong builds

Use confirmat screws on flat packs. They grip dense cores well.

Cut dados for carcass strength. Glue faces, not just edges.

Choose pocket screws for quick frames. Hide holes on inside faces.

Add biscuits or dominos for fast alignment. They speed clamping.

Pin nails hold trims during set. Follow with a light clamp.

Adhesives and bonds

PVA covers most shop needs. Pick crosslink types for tougher cycles.

PU glue fills tiny gaps and handles damp parts.

Epoxy bonds mixed materials and odd fits.

Apply even films. Starved joints fail early.

Clamp with moderate pressure. Too much squeezes out glue.

Respect cure windows. Cold rooms slow reactions.

Risk control on long lanes

Sea air adds moisture. We paint edges and wrap tight.

Terminal moves can be rough. We guard corners and faces.

Paperwork can stall cargo. We prep local docs in advance.

Rates swing. We book early and map split routes when needed.

Free time differs by port. We track rules and warn early.

Sustainability notes that help bids

Legal harvests matter. We keep chain-of-custody flows.

Waste falls as we optimize layups and trims.

Offcuts become energy or small parts.

Tight packages raise cubic use per box.

Transport plans limit idle time and extra moves.

Buyer checklist for fast, clean orders

– End use and sites (dry, humid, wet).

– Grades and patch rules for faces.

– Core type, density, and pull targets.

– Bond class and formaldehyde level.

– Sizes, tolerances, and sanding passes.

– Packing style, labels, and barcodes.

– Route plan, port rules, and free time.

– Photos, tests, and batch codes.

– Backup sizes for swaps if needed.

ROCPLEX service steps that save time

We confirm specs in plain words. No jargon walls.

Our team blocks line time for repeats.

Share live photos from the floor.

Barcode packs and send labels ahead.

Update ETDs and vessel shifts early.

Keep claim paths simple and fast.

Cost and yield levers you can pull

Match sizes to nests. Waste drops fast with smart grids.

Pick thinner faces on hidden sides. Save cost without pain.

Use combo cores where loads stay light.

Consolidate POs by grade and route.

Swap to near ports when space tightens.

Ship sample pallets in mixed boxes. Prove options without big bets.

Field fixes for urgent issues

Face chip at edges? Run a light climb pass.

Small void near a hinge? Pack and glue a plug.

Raised grain after stain? Sand back and reseal.

Loose screw pull? Step up diameter or add inserts.

Cupping on thin wide sheets? Weight stack for a day.

Glue starve on a joint? Inject thin epoxy and clamp.

Packaging that protects your margin

We wrap with heavy film and top caps.

Edge paint seals pores on all sides.

Corner guards stop clamp crush points.

Bands cross both ways for firm holds.

Door airbags curb shift on rail.

Clear marks show lift points and weight.

Team training that pays back fast

We share short guides for shop floors.

Labels match pack maps and pick lists.

QR codes link to spec sheets and MSDS.

Wall charts cover storage and seal steps.

Tool crib cards list blade and bit choices.

Small habits save hours and claims.

Extended FAQ for buyers

Will this material hold screws near edges?

Yes, dense cores hold well. Pre-drill near tight edges. Keep good clearance.

Can I stain to look like walnut?

Yes. Use toner coats or stain systems. Test on offcuts first.

What about curved parts?

Kerf cut backs for tight bends. Use thin laminations with forms for small radii.

Do you supply cut-to-size parts?

Yes. Share DXF or lists. We trim and label per nest plan.

Are 5×5 sheets available? Yes. Baltic formats exist. We also stock metric sizes for Euro lines.

How do I keep color stable over time?

Use UV-stable finishes. Store away from direct sun before install.

Can you match panels across lots? Yes. We group by tone and face grade. Photos help set targets.

Birch wood in real projects

Retail fit-outs need clean, tough faces. Our HPL skins take hits and wipe clean.

School furniture needs strong joints. Dense cores resist loose screws.

Tool makers need accurate jigs. Baltic layers keep shapes true.

Stage builders need fast cycles. Film faces release and reset quickly.

Crate makers need safe weights. Combo cores balance cost and strength.

How we reduce defects before they ship

We scan cores for gaps and patches.

Press crews log time, heat, and pressure.

QA cuts witness strips on each run.

Teams track moisture and bond strength.

Supervisors review photos by lot.

We hold back any doubtful packs.

ROCPLEX birch wood promise

Protect your time and margin.

Keep specs steady across runs.

Say what we will do and do it.

Support claims fast and fair.

We grow with partners who value trust.

Press note and contact

Editors may request images, plant shots, and test pages.

Buyers may request samples, batch maps, and size lists.

ROCPLEX supplies trade buyers across many regions with steady service and calm plans.

Ready-to-publish assets

– Product photos with alt text and filenames.

– Spec sheet PDF for quick downloads.

– FAQ block for site use.

– Packing and label guide for yards.

– Short video clips from the mill floor.

Birch plywood

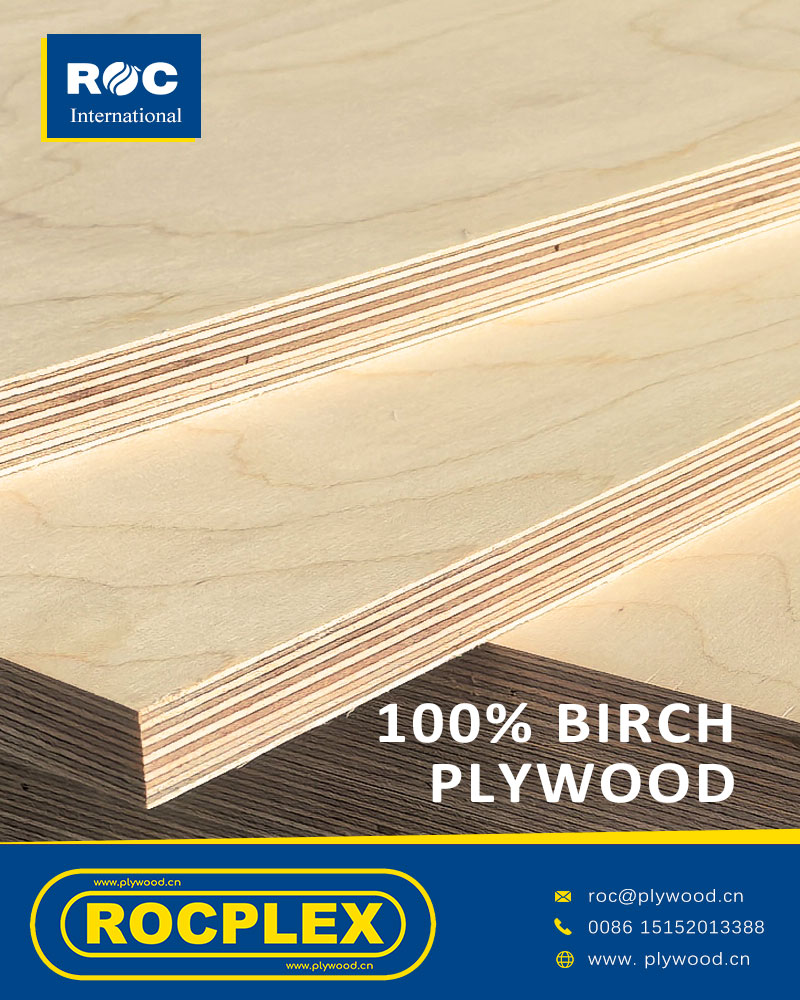

Birch Plywood Introduction

Birch plywood is one of the most popular wood panels in the building materials industry. It is known for its strength, smooth surface, and stability. At ROCPLEX, we produce birch plywood with strict standards for quality and durability. Wholesalers, furniture factories, and construction companies choose our products for reliable supply. This versatile panel is suitable for furniture, decoration, and structural uses. It provides a cost effective solution without sacrificing performance.

What is Birch Plywood

Birch ply board is made from multiple thin layers of birch veneer. The veneers are bonded together with strong adhesive under heat and pressure. This cross laminated structure provides stability and strength. Compared with solid wood, it is less likely to warp or split. Birch plywood has a fine grain surface that is easy to finish. ROCPLEX uses advanced production methods to guarantee consistent quality.

Key Features of Birch Plywood

Birch ply has excellent load bearing strength. The smooth surface makes it ideal for painting and laminating. It is lightweight yet durable for many applications. ROCPLEX ensures every sheet passes quality checks. Our panels meet international safety and environmental standards. This product offers long service life and reliable performance. It combines cost efficiency with attractive appearance.

Applications of Birch Plywood

Furniture plywood made from birch is highly valued for cabinets and tables. Interior plywood panels are used for wall lining and partitions. Construction plywood serves as flooring, roofing, and structural elements. Birch veneer ply is applied in decorative furniture. Decorative plywood is popular for modern interiors. Plywood sheets are also used in packaging and transport boxes. ROCPLEX supplies birch ply to global markets with dependable quality.

Types of Birch Plywood

Birch veneer plywood is used for furniture and decoration. Hardwood plywood made from birch combines strength with fine surface. Interior plywood is chosen for doors, ceilings, and panels. Construction plywood is designed for heavy duty projects. Plywood sheets cover a wide range of industrial and commercial needs. ROCPLEX offers decorative plywood for premium applications.

Why Choose ROCPLEX Birch Plywood

ROCPLEX is a trusted global manufacturer of birch ply board. We operate advanced factories with strict quality control. Our products carry FSC and PEFC certification for sustainability. We ensure timely delivery and large volume supply. Wholesalers and contractors rely on us for stable quality. Our brand stands for trust, safety, and consistent performance. Clients worldwide choose ROCPLEX for long term cooperation.

Frequently Asked Questions

Is birch ply strong?

Yes, it provides excellent strength for construction and furniture.

What is birch ply used for?

It is used in furniture, interiors, and building projects.

Is birch ply good for furniture?

Yes, its fine surface is ideal for cabinets and tables.

How is birch plywood different from hardwood plywood?

Birch ply has smoother surface and lighter weight.

Is birch ply waterproof?

Standard panels resist moisture but are not fully waterproof.

Birch Plywood Build with Confidence

Birch plywood is a reliable and versatile wood panel. ROCPLEX supplies high quality panels for wholesalers, builders, and furniture makers. Our products combine strength, durability, and fine surface quality. We invite global buyers to connect with ROCPLEX for trusted supply. Together we deliver dependable solutions for construction and furniture projects.

Edge Form LVL – SENSOedge

SENSO Edge Form LVL is engineered for concrete slab formwork, offering high strength, straightness, and durability. As a reliable edge form supplier, SENSO ensures precise LVL boards ideal for professional formwork applications.

BS1088 Certified Marine Plywood

ROCPLEX 18mm Marine Plywood sheets with waterproof WBP bonding and smooth hardwood veneers provide high strength, moisture resistance, and long-term durability, ideal for boat building, dock construction, wet-area cabinetry, and exterior marine applications.

Hardwood plywood

What is Hardwood Plywood?

Hardwood plywood is made by gluing hardwood veneers in layers under pressure. Each layer crosses the next, reducing swelling and shrinkage. Unlike solid wood, this panel stays stable even with changes in moisture. The sheets come in many thicknesses and grades, covering both decorative and structural needs. For furniture use, it gives a clean face for finishing. For builders, it provides strength and steady performance. In addition, many suppliers now use certified wood, supporting sustainable trade.

Benefits of the Material

The panel resists bending because of its cross-grain design. This stability makes it safe in both dry and humid areas.

It provides a smooth face that accepts paint, veneer, or laminates. As a result, it offers endless design choices.

The board holds screws and nails securely. Therefore, it works well for cabinets, floors, and wall panels.

In addition, wholesalers choose it because the hardwood plywood price remains fair while the quality stays high.

Wide Range of Applications

Furniture makers use the panel for cabinets, wardrobes, and tables. Its surface allows easy finishing.

Builders install it in floors, walls, and roofing. In these uses, it keeps its shape for years.

Interior designers apply it in wall cladding and panels. For example, the natural grain gives a premium look.

Meanwhile, packaging firms use it for export boxes and crates. It protects goods while reducing total weight.

Role in Global Trade

International buyers trust steady supply. Hardwood plywood wholesale shipments lower costs and simplify distribution.

Suppliers provide clear labeling and strong packing. This helps buyers save time in handling.

As a result, demand for housing and furniture keeps hardwood plywood price stable. Buyers rely on it for consistent quality.

Importance of Trusted Suppliers

Strong suppliers check every sheet before shipment. They test bonding strength, flatness, and smoothness.

In addition, they provide certificates for quality and eco-friendly sourcing. This builds trust for global buyers.

Wholesalers also receive technical support. Reliable suppliers explain grades, thickness choices, and transport options.

Factors Behind the Price

The type of hardwood veneer affects cost. Premium faces add more beauty but increase price.

Sheet thickness also changes cost. Thicker panels mean more material and higher strength.

In addition, freight distance and shipping space impact final hardwood plywood price. Reliable suppliers manage logistics to reduce risks.

Value for Furniture Production

Furniture producers choose this panel for stable performance and smooth faces. It cuts waste and saves time.

It holds screws well, so joints stay strong. This improves durability in chairs, cabinets, and beds.

In addition, the board accepts many finishes. It adapts to classic or modern styles easily.

Choosing the Right Sheets

Buyers should match thickness and grade to the project. Thin boards fit drawers and cabinet backs. Thicker ones suit floors and roofs.

Moisture-resistant grades fit kitchens and bathrooms. Standard panels serve well in dry rooms.

Therefore, working with a skilled supplier ensures the right match. This saves money and avoids waste.

Wholesale Solutions

Large buyers often prefer bulk supply. Hardwood plywood wholesale options keep stock steady and costs low.

Custom packing and flexible shipping schedules support efficient business. As a result, wholesalers reduce handling time.

Meanwhile, demand for this material keeps rising. Experienced suppliers focus on steady service and quality.

The Lasting Value of ROCPLEX Hardwood Plywood in Construction and Furniture

ROCPLEX hardwood plywood remains a trusted choice for builders, wholesalers, and furniture makers worldwide. It offers strength, a smooth finish, and excellent value for money.

Our team ensures steady supply, while competitive hardwood plywood price supports long-term partnerships with global buyers. As a result, ROCPLEX continues to stand as a reliable brand for quality wood products.

Combi plywood

What is Combi Plywood?

Combi plywood is a board built by combining hardwood veneers with softwood layers. The hardwood provides strength, while the softwood lowers weight and cost. Each layer is cross-bonded, which increases stability and reduces swelling. Compared with full hardwood plywood, this panel offers a balance of performance and price. Combi plywood sheets come in different grades, thicknesses, and surface finishes. Builders use them for walls, floors, and formwork. Furniture makers apply them in cabinets and shelves. With wide applications and fair cost, combi plywood remains a smart choice for global buyers.

Key Benefits of Combi Plywood

Combination core plywood gives reliable strength. The hardwood layers increase durability, while the softwood keeps it light.

The panel resists bending and holds shape well. This ensures safe use in both dry and humid spaces.

It offers a smooth surface for laminates, veneers, or paint. As a result, it adapts to many design styles.

Combi plywood price is usually lower than full hardwood panels. Therefore, wholesalers and buyers find it more affordable.

Applications in Furniture and Construction

Furniture makers use combination core plywood for cabinets, shelves, and wardrobes. It is easy to cut, drill, and finish.

Builders use it for flooring, wall sheathing, and roofing. In these roles, it performs reliably under load.

Interior designers value its flexibility. For example, combination core plywood accepts high-end veneers for decorative panels.

Packaging companies also use it for crates and pallets. The light weight reduces freight costs while keeping goods safe.

Combi Plywood in Global Trade

Combi plywood suppliers serve both local and export markets. Bulk shipments support stable supply for wholesalers.

Custom packing and clear labeling improve efficiency in logistics. This allows fast handling at ports and warehouses.

The rising demand for affordable wood panels keeps combi plywood wholesale orders steady. Buyers trust it for cost and quality.

Why Work with Trusted Combi Plywood Suppliers

Professional suppliers test every sheet before shipment. They check bonding, moisture, and surface smoothness.

In addition, they offer certificates for quality and eco-friendly sourcing. This builds trust with global buyers.

Suppliers also support wholesalers with advice on grades, thickness, and applications. This helps reduce mistakes and saves cost.

Factors Affecting Combi Plywood Price

Species of hardwood used in the face layers affects the cost. Premium veneers add beauty but raise price.

Panel thickness influences price. Thicker sheets need more material and increase cost.

Freight distance and shipping conditions also change the final price. Reliable suppliers manage logistics for stable costs.

Value for Furniture Makers

Furniture producers prefer combination core plywood for its mix of strength and light weight. It reduces waste and speeds up work.

The panel holds screws well, making it ideal for joints. This ensures furniture lasts longer.

It also accepts a wide range of finishes. Therefore, designers can meet both modern and classic styles.

Choosing the Right Combi Plywood Sheets

Buyers should choose thickness and grade based on use. Thin panels suit drawers, while thicker ones suit floors.

Moisture-resistant grades are best for kitchens or bathrooms. Standard grades perform well in living spaces.

Suppliers guide buyers in selecting the right sheet. As a result, projects stay within budget and quality targets.

Wholesale Solutions for Global Buyers

Large buyers prefer combi plywood wholesale shipments. Bulk supply keeps costs low and stock reliable.

Suppliers offer flexible shipping schedules, helping buyers manage supply chains.

Demand for this product grows worldwide. Trusted suppliers focus on steady quality and customer support.

Value of ROCPLEX Combi Plywood for Buyers and Builders

ROCPLEX combi plywood gives buyers the right balance between performance and price. It supports strong furniture, reliable construction, and smooth finishes.

Our brand ensures consistent supply, while competitive combi plywood price keeps it affordable for wholesalers. As a result, ROCPLEX remains a trusted name in global wood products.

Fancy MDF

What is Fancy MDF?

Fancy MDF is a type of medium density fiberboard finished with decorative surfaces. These surfaces can be colored, laminated, or veneered. The board is made by pressing wood fibers under heat and pressure. A smooth face makes it suitable for painting or coating. It combines strength with a refined appearance, making it popular in furniture and interior design. veneered MDF sheets are available in multiple grades and thicknesses. Global Veneer MDF suppliers provide eco-friendly options that meet strict standards. For buyers, it offers both performance and design flexibility.

Key Benefits of Fancy MDF

Fancy MDF has a uniform core, giving it stable strength. It does not warp or split easily.

The surface is smooth and ready for laminates, paint, or veneer. As a result, it reduces finishing work.

Designers prefer it for decorative appeal. Veneer MDF board comes in many colors and patterns.

For wholesalers, veneered MDF price offers good value. It balances cost with durability and design quality.

Applications in Furniture and Interiors

Furniture producers use fancy MDF for cabinets, wardrobes, and shelving. It cuts cleanly and holds fasteners well.

Interior designers rely on it for wall panels, partitions, and ceiling elements. Its finish creates a premium look.

Retail stores use it for display units and counters. Decorative patterns enhance brand presentation.

Architects specify it in modern projects. For example, colored MDF board adds style to hotels and offices.

Fancy MDF in Global Trade

Fancy MDF wholesale orders meet the growing demand in housing and retail. Export shipments support cost savings.

Suppliers offer flexible packing and shipping. This helps buyers reduce handling time.

As a result, decorative MDF suppliers remain a key link between production and large-scale buyers worldwide.

Why Work with Trusted Fancy MDF Suppliers

Reputable suppliers test each sheet for density, moisture, and finish quality. This ensures consistency.

Many provide certifications for eco-friendly materials. Buyers gain confidence in sustainable sourcing.

Reliable fancy decorative MDF suppliers also support customers with design catalogs and technical advice. This improves selection and use.

Factors Affecting Fancy MDF Price

Surface design impacts cost. Laminated or veneered finishes raise the price.

Board thickness also changes the price. Thicker boards need more raw material.

Shipping and packaging costs add to the final price. Wholesale buyers benefit from bulk delivery.

Value for Furniture Makers

Furniture makers benefit from its smooth face and stable core. This reduces sanding and finishing work.

It accepts screws and adhesives well. Therefore, it ensures long-lasting joints in cabinets and tables.

Decorative MDF also allows many design choices. It adapts easily to classic or modern styles.

Choosing the Right Fancy MDF Sheets

Buyers should pick thickness and finish based on project needs. Thin sheets work for paneling. Thicker boards suit furniture.

Moisture-resistant grades fit kitchens and bathrooms. Standard boards are ideal for bedrooms and living rooms.

Trusted suppliers guide buyers to the right choice. This ensures quality and cost control.

Wholesale Solutions for Buyers

Large buyers prefer fancy MDF wholesale supply for stable costs. Bulk shipments reduce price per sheet.

Suppliers provide custom packing and fast delivery. This supports project deadlines.

Global demand continues to rise. Reliable suppliers focus on quality and service for wholesalers.

ROCPLEX Fancy MDF Adds Lasting Value to Global Projects

ROCPLEX fancy MDF offers the right mix of design, strength, and price. It supports builders, furniture makers, and wholesalers worldwide.

Our brand delivers consistent supply and durable panels. With fair MDF price and many options, ROCPLEX remains a trusted partner in decorative wood solutions.

Post time: Sep-08-2025