Door Skin

ROCPLEX Door Skin

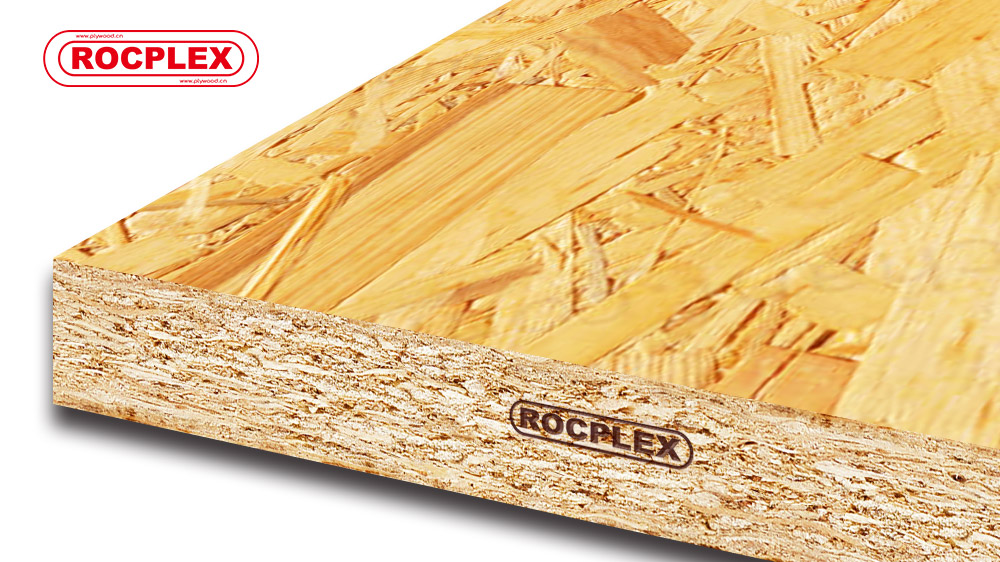

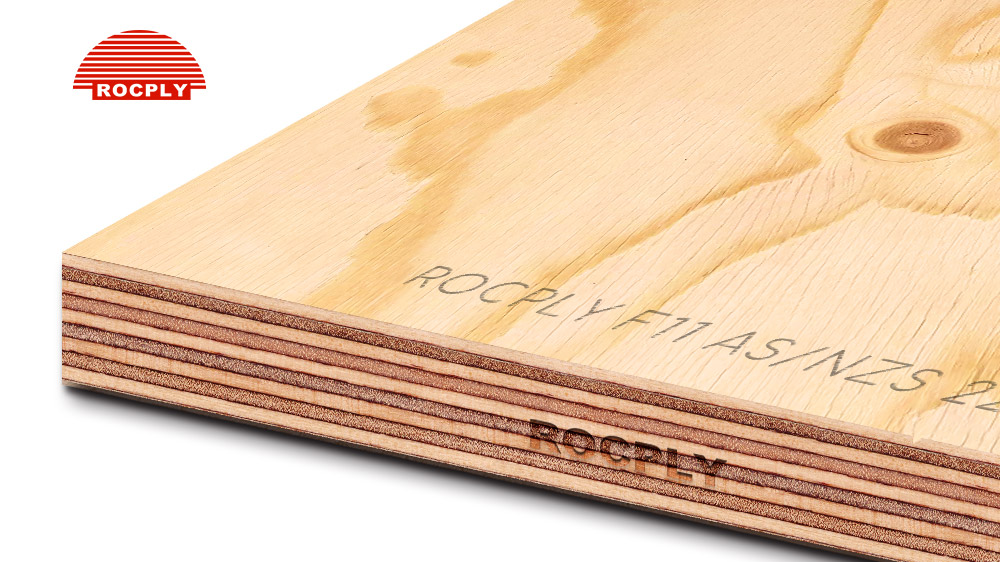

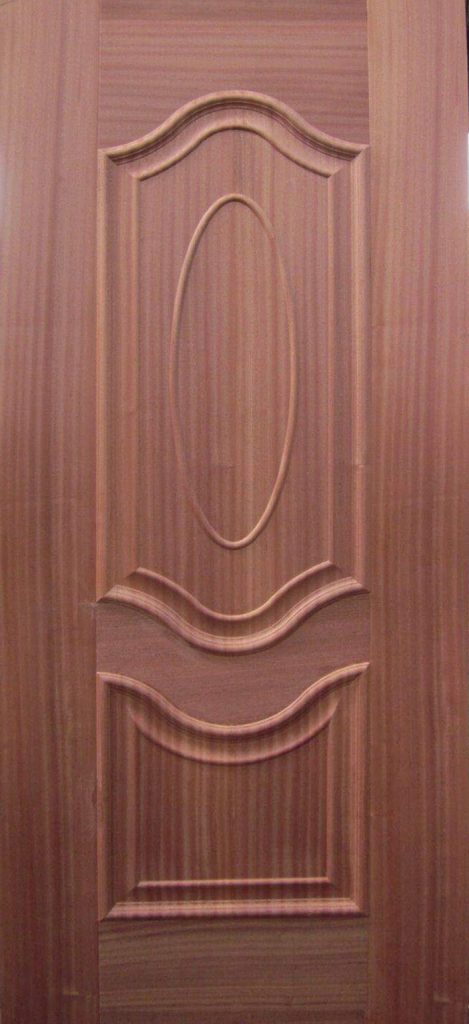

ROCPLEX Door Skin panels are manufactured to meet the demands of door manufacturers, furniture producers, and interior system designers. Using a base of hardwood or composite cores, each skin is laminated with a high-quality decorative surface that may include natural veneer, melamine film, or plain MDF.

Designed for uniform thickness and strong adhesion, ROCPLEX Door Skin eliminates the problems of bubbling, delamination, and warping often seen in low-grade products. It provides a balanced surface for painting, veneering, or lamination, delivering a premium appearance and structural dependability in door production lines.

The panels are pressed at high temperatures to achieve a rigid structure and smooth surface. With consistent dimensions and tight thickness tolerances, ROCPLEX Door Skin offers ease of processing in automatic press systems and CNC machinery, reducing waste and enhancing productivity.

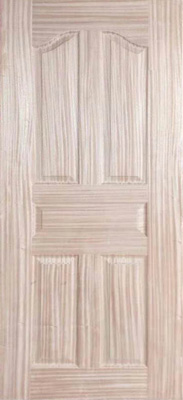

Options are available in paint-grade skins, molded designs, and deep wood grain textures. These allow ROCPLEX customers to offer variety in residential, commercial, and institutional door markets.

>>>

ROCPLEX Door Skin Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 28 | 2100-3050 | 920-1220 | Particle Board | AA |

| 30 | 2100-3050 | 920-1220 | Particle Board | AA |

| 33 | 2100-3050 | 920-1220 | Particle Board | AA |

| 35 | 2100-3050 | 920-1220 | Particle Board | AA |

| 36 | 2100-3050 | 920-1220 | Particle Board | AA |

| 38 | 2100-3050 | 920-1220 | Particle Board | AA |

| 40 | 2100-3050 | 920-1220 | Particle Board | AA |

| 45 | 2100-3050 | 920-1220 | Particle Board | AA |

| 30 | 2100-3050 | 920-1220 | Particle Board | AA |

| 40 | 2100-3050 | 920-1220 | Particle Board | AA |

>>>

ROCPLEX Door Skin Details

>>>

ROCPLEX Door Skin Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | G2S | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | / | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 E1 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 650-720 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX particle board is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX Door Skin Features & Benefits

- Excellent Surface Quality

- Smooth finish ideal for direct painting, veneer lamination, or decorative films.

- Dimensional Stability

- Resistant to warping, shrinking, or expansion in variable humidity conditions.

- Design Versatility

- Available in melamine, veneer, and molded patterns for multiple design themes.

- Time-Saving Processing

- Consistent thickness and calibration ensure minimal machine setup and fast throughput.

- Moisture and Crack Resistance

- Engineered to withstand climate fluctuations and reduce surface cracking in transit or use.

- Sustainable Material Options

- Made with plantation wood and low-emission adhesives, with FSC certification available on request.

>>>

ROCPLEX Door Skin Certified By

|  |  |  |

ROCPLEX Door Skin is widely used in hollow core doors, flush doors, decorative entry doors, and modular furniture components.

Factories producing ready-to-assemble wardrobes, kitchen doors, and closets also utilize these panels due to their dimensional stability and surface versatility.

In interior fit-out projects, ROCPLEX Door Skin provides aesthetic uniformity, ease of cutting, and edge treatment, making it suitable for both high-end commercial spaces and economy-grade housing projects.

Upgrade your door manufacturing process with ROCPLEX Door Skin. Contact ROCPLEX today for pricing, technical data, and global shipping support tailored to your volume needs.

>>>

ROCPLEX Door Skin FAQ

Q: What is ROCPLEX Hollow Particle Board?

A: ROCPLEX Hollow Particle Board is a lightweight panel with an internal tubular structure, designed to reduce weight while maintaining rigidity.

Q: What is the board mainly used for?

A: It is ideal for interior doors, partitions, and large furniture panels where lower weight is essential for ease of use and cost savings.

Q: How is the hollow structure formed?

A: The board is made by arranging chipboard webs in a grid or tube pattern inside a solid particleboard frame, then pressing with surface layers.

Q: What are the thickness options?

A: Standard thicknesses range from 28mm to 45mm. Custom sizes are available upon request for volume-based orders.

Q: Can ROCPLEX Hollow Particle Board support hardware fittings like hinges and locks?

A: Yes. The board is reinforced around the frame edges to support door hinges, locks, and hardware without splitting or weakening.