Form MDO Plyform

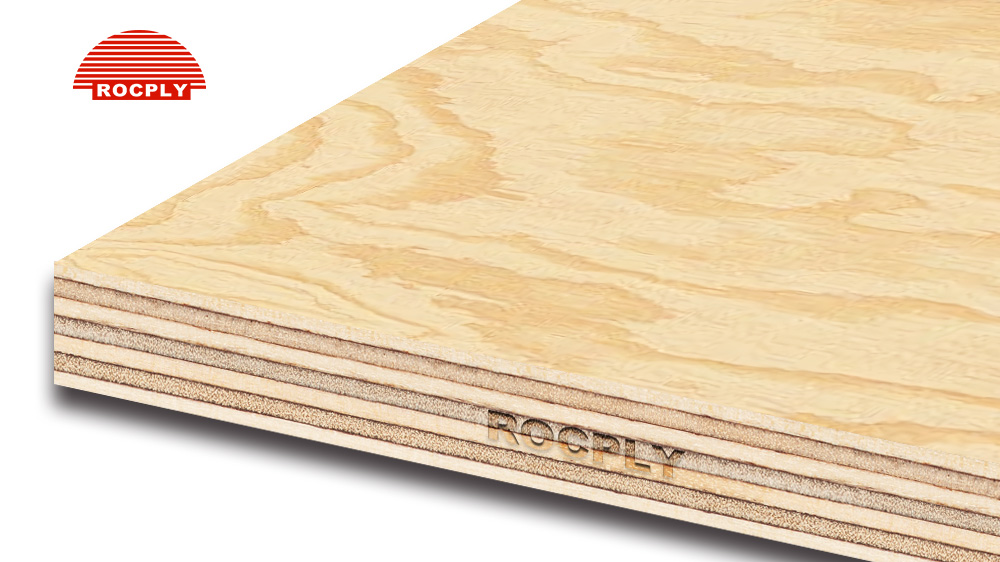

ROCPLEX Form MDO Plyform is developed to deliver excellent results in concrete form applications requiring durability and visual consistency. The medium-density overlay on the panel face resists moisture and abrasion while offering a smoother surface than traditional form plywood.

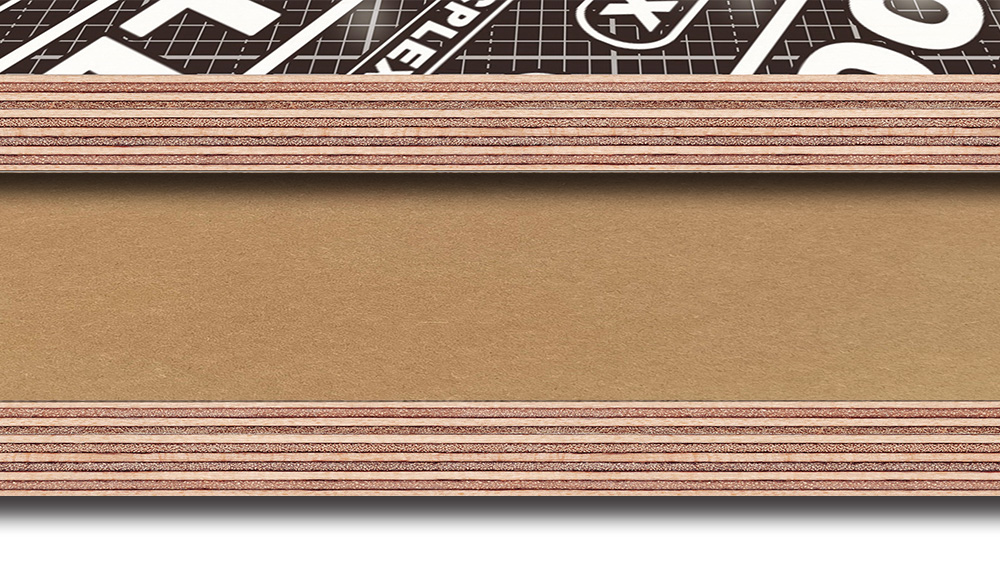

Form MDO Plyform is constructed with high-quality hardwood or softwood veneers bonded using waterproof adhesives. This core structure ensures strength and prevents delamination during repeated pours. The MDO coating significantly improves panel longevity and reduces the need for surface patching.

Unlike conventional plywood, this product offers better paintability and a matte finish. That makes it especially useful for concrete forms where surface quality matters. With a resin-treated fiber overlay bonded to the face under heat and pressure, Form MDO Plyform delivers a clean and stable finish after stripping.

ROCPLEX maintains rigorous internal testing to ensure dimensional accuracy and consistent load-bearing strength. Every sheet meets structural standards and is ideal for industrial and commercial building sites where formwork panels must be reused without failure.

|

||

| Form MDO Plyform |

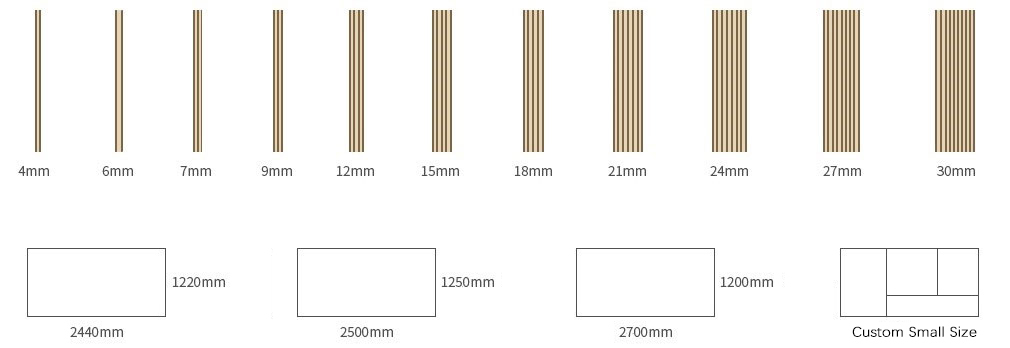

| Thickness (mm) | Length (mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Birch / Hardwood | AA |

| 7 | 2440 | 1220 | Birch / Hardwood | AA |

| 9 | 2440 | 1220 | Birch / Hardwood | AA |

| 12 | 2440 | 1220 | Birch / Hardwood | AA |

| 15 | 2440 | 1220 | Birch / Hardwood | AA |

| 17 | 2440 | 1220 | Birch / Hardwood | AA |

| 18 | 2440 | 1220 | Birch / Hardwood | AA |

| 19 | 2440 | 1220 | Birch / Hardwood | AA |

| 25 | 2440 | 1220 | Birch / Hardwood | AA |

| 28 | 2440 | 1220 | Birch / Hardwood | AA |

■ ROCPLEX MDO plywood panels feature a medium-density overlay that improves concrete surface appearance and supports repeated use.

■ The fiber overlay is bonded with heat and pressure to a core built from high-grade veneers, ensuring strength and stability.

■ Each panel is manufactured to strict tolerances to minimize warping and ensure dimensional accuracy across formwork assemblies.

■ The matte surface helps prevent concrete surface defects and minimizes surface treatment work after form stripping.

■ Water-resistant adhesives keep the plywood bonded during wet pours, reducing the risk of swelling or delamination.

■ MDO coating provides a tighter, more durable finish than standard plywood. This lowers labor and finishing costs post-pour.

■ ROCPLEX MDO panels can be easily cut, drilled, or nailed without splintering, making site installation faster and safer.

■ Form MDO Plyform maintains its shape under heavy concrete pressure, reducing deflection and ensuring slab integrity.

■ Produced using FSC and PEFC certified wood, this product supports sustainability in building practices without sacrificing performance.

ROCPLEX Form MDO Plyform FAQ

Q: What is ROCPLEX Form MDO Plyform?

A: ROCPLEX Form MDO Plyform is a medium density overlay plywood designed for concrete formwork. It features a resin-treated surface for smooth concrete finishes and repeated reuse.

Q: What are the advantages of MDO plywood in formwork?

A: MDO plywood offers a matte surface that delivers uniform concrete textures. It also resists moisture, reduces air pockets, and ensures clean form removal.

Q: How many times can MDO formwork panels be reused?

A: Depending on jobsite handling and form release practices, ROCPLEX MDO plywood can be reused many times without loss of form strength or surface quality.

Q: Does ROCPLEX use sustainable materials?

A: Yes. ROCPLEX Form MDO Plyform is manufactured using FSC and PEFC certified veneers from sustainably managed forests.

Q: How does MDO compare to HDO plywood?

A: MDO provides a matte finish and is easier to paint. While HDO offers higher surface durability, MDO is more economical for applications where a smooth surface is sufficient.