Hexa Grip Plywood

ROCPLEX Hexa Grip Plywood

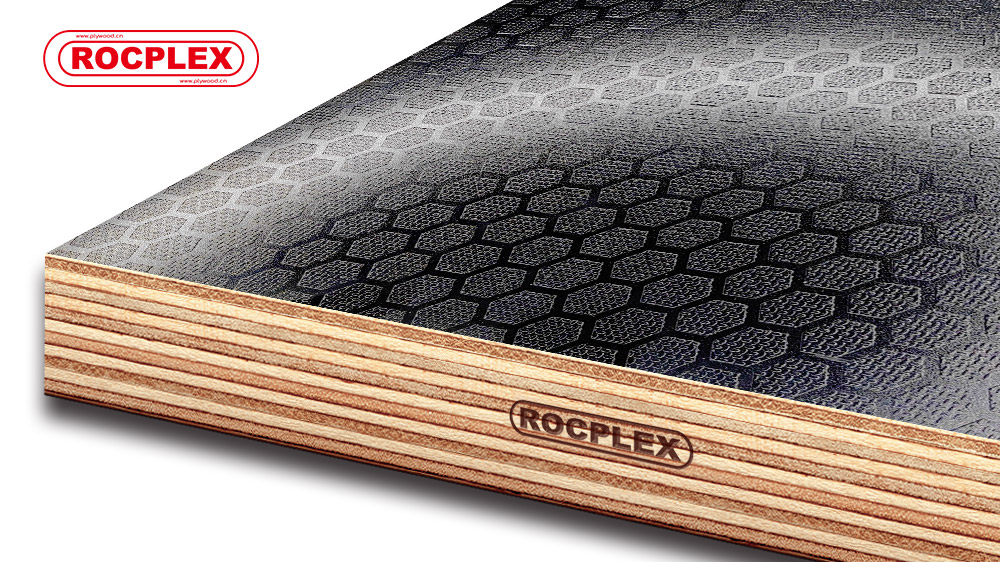

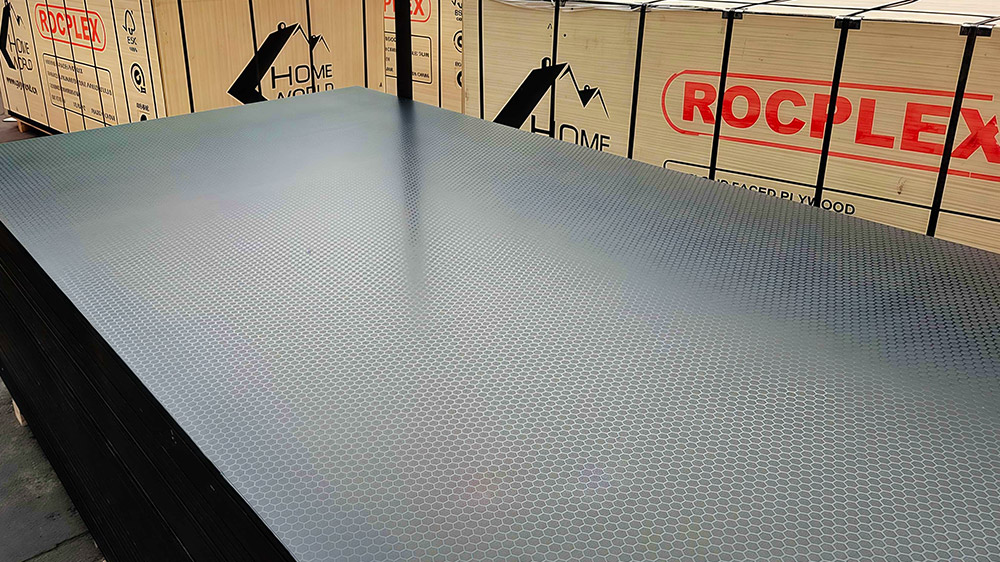

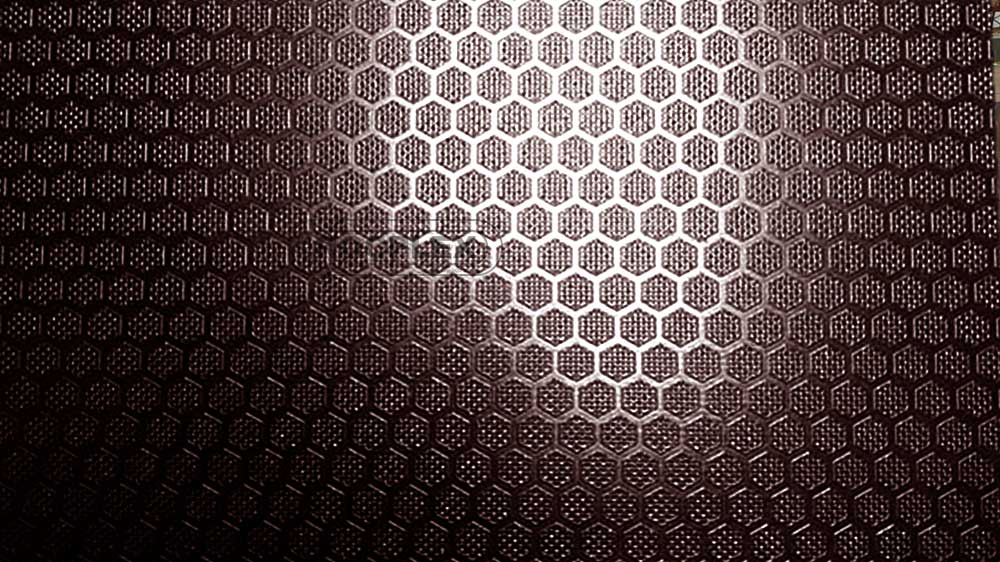

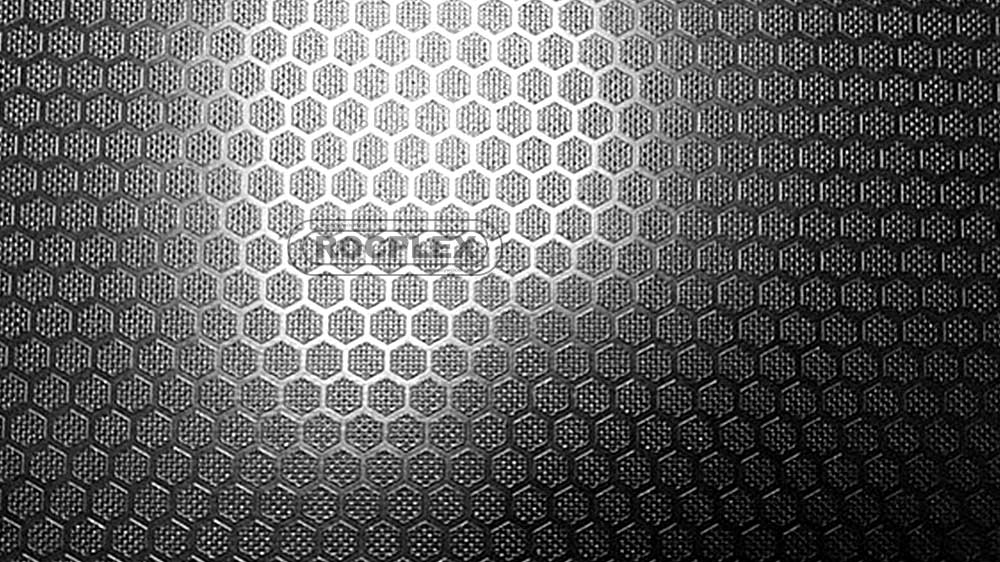

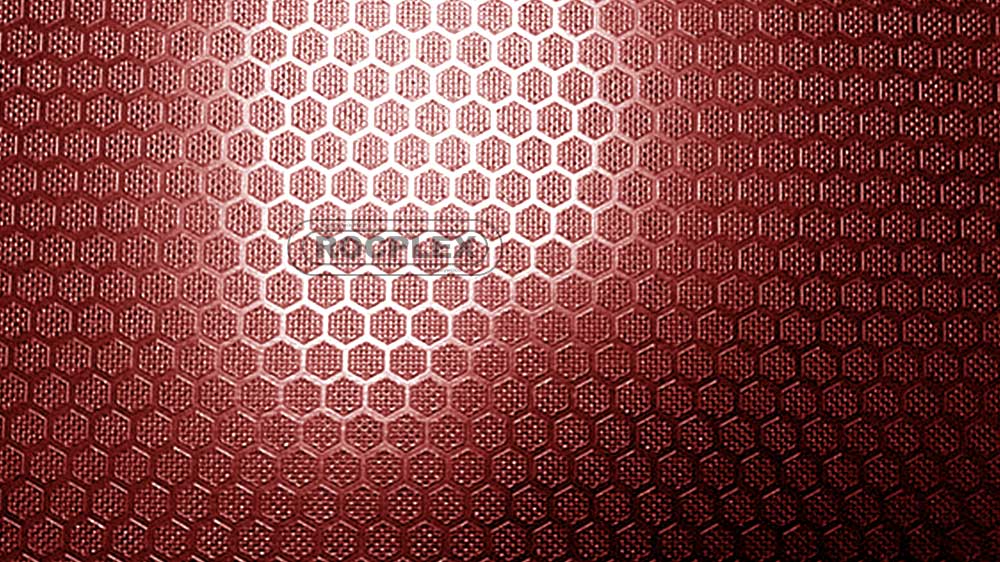

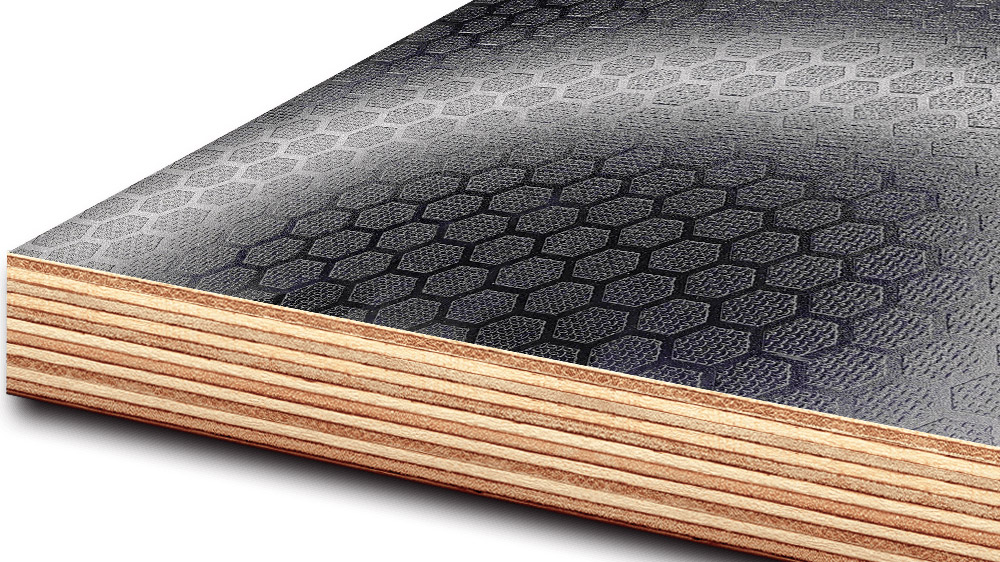

ROCPLEX Hexa Grip Plywood is a durable film-faced board with a high-friction surface. It is manufactured using phenolic film overlay pressed onto both faces of the plywood. The top side features a textured hexagonal pattern that enhances grip, even in wet or dusty conditions.

The plywood core consists of cross-laminated hardwood or birch veneers bonded with waterproof WBP adhesive. This construction delivers structural strength, impact resistance, and reliable dimensional stability during heavy-duty use.

The surface coating is wear-resistant and easy to clean. It withstands abrasion, chemicals, and weather exposure, making it suitable for indoor and outdoor use. The reverse side is coated with smooth phenolic film to maintain balance and reduce moisture penetration.

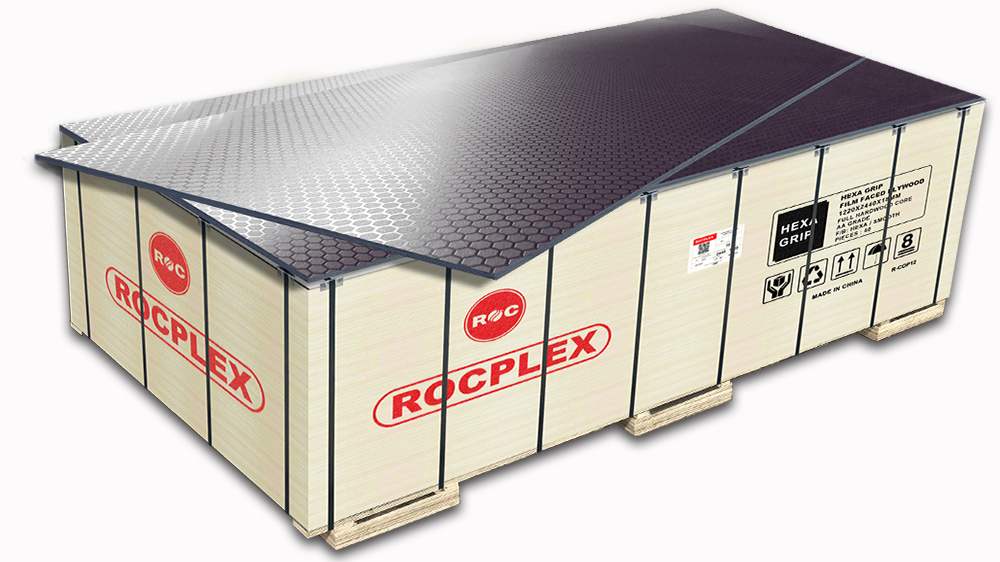

ROCPLEX ensures strict quality control in pressing, bonding, and calibration. Panels are produced with tight dimensional tolerance and sealed edges for improved durability during installation and transport.

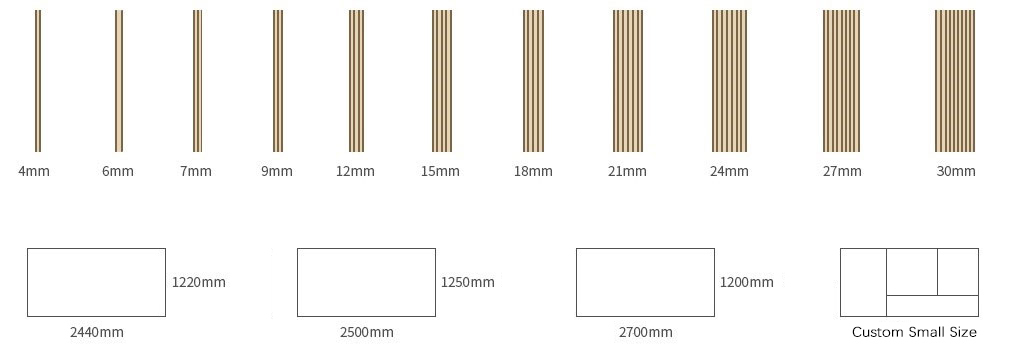

Standard sizes include 1220mm x 2440mm and 1500mm x 3000mm, with thickness options ranging from 9mm to 28mm.

>>>

ROCPLEX Hexa Grip Plywood Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Hardwood / Birch | AA |

| 7 | 2440 | 1220 | Hardwood / Birch | AA |

| 9 | 2440 | 1220 | Hardwood / Birch | AA |

| 12 | 2440 | 1220 | Hardwood / Birch | AA |

| 15 | 2440 | 1220 | Hardwood / Birch | AA |

| 17 | 2440 | 1220 | Hardwood / Birch | AA |

| 18 | 2440 | 1220 | Hardwood / Birch | AA |

| 19 | 2440 | 1220 | Hardwood / Birch | AA |

| 25 | 2440 | 1220 | Hardwood / Birch | AA |

| 28 | 2440 | 1220 | Hardwood / Birch | AA |

>>>

ROCPLEX Hexa Grip Plywood Regular Optional Colors

>>>

ROCPLEX Hexa Grip Plywood Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | Antislip | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | A Bond | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 630-720 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX Hexa Grip Plywood Features & Benefits

- Slip-Resistant Hexa Pattern Surface

- Provides strong underfoot grip to reduce slipping in wet, dusty, or inclined conditions.

- Strong Structural Core

- Built from cross-laminated hardwood or birch veneers to support heavy loads and repeated use.

- Weatherproof Bonding

- WBP adhesive offers resistance to water, humidity, and temperature fluctuations.

- Durable Film Coating

- Phenolic film protects against abrasion, chemicals, and surface wear during extended service.

- Edge Sealed for Longevity

- Edges are coated with waterproof paint to prevent moisture ingress and improve durability.

- Multiple Sizes and Thicknesses

- Available in standard and custom sizes to fit trucks, trailers, scaffolds, and industrial floors.

>>>

ROCPLEX Hexa Grip Plywood Certified By

|  |  |  |

ROCPLEX Hexa Grip Plywood is widely used in trailer floors, truck beds, and vehicle platforms where skid resistance is essential.

It is ideal for warehouse walkways, stair treads, and loading ramps to improve safety and reduce slip hazards.

The board performs well in construction sites as scaffold platforms or temporary flooring panels exposed to frequent foot traffic.

It is also suitable for industrial shelving, container flooring, and portable stages where durability and non-slip surface are required.

Need a non-slip plywood solution for floors, trailers, or platforms? Contact ROCPLEX now to order Hexa Grip Plywood engineered for safety and strength.

>>>

ROCPLEX Hexa Grip Plywood FAQ

Q: What is Hexa Grip Plywood?

A: Hexa Grip Plywood is a slip-resistant film-faced panel featuring a hexagonal textured surface. It is used in flooring, transport, and industrial applications.

Q: Where is this plywood commonly used?

A: It is widely used in truck beds, trailer floors, scaffold decks, loading ramps, container floors, and warehouse platforms.

Q: Is ROCPLEX Hexa Grip Plywood waterproof?

A: The panel is bonded with WBP (Water Boil Proof) glue and sealed edges, offering excellent resistance to moisture and humidity.

Q: How is ROCPLEX Hexa Grip Plywood maintained?

A: The surface is easy to clean with mild detergent and water. It resists most oils and chemicals encountered in industrial use.

Q: How can I order samples or get technical support?

A: Contact the ROCPLEX sales team through the official website or email to receive technical data, pricing, or physical samples.