What makes true BS1088 marine plywood

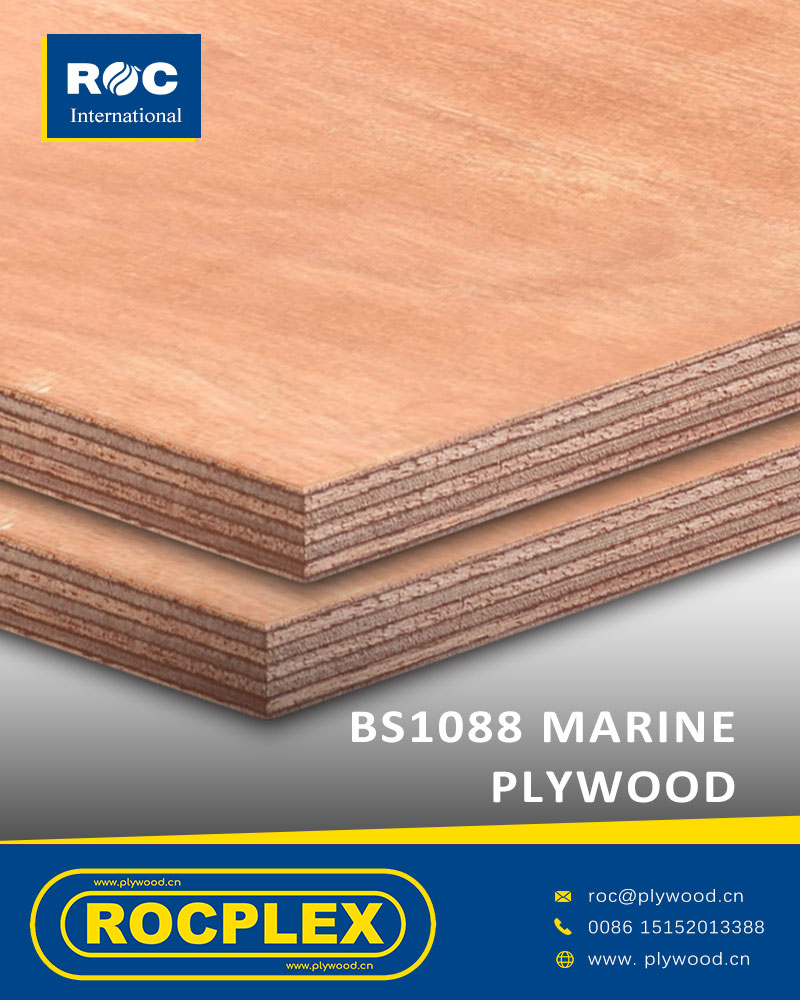

Standards protect your brand. BS1088 marine plywood sets clear targets for build and bond.

It calls for high-grade veneers and strict gap control.

Glue lines resist heat, steam, and salt cycles.

We align runs with the rule set. We log press data and moisture by batch.

You can trace each pack back to a shift. That trace keeps audits simple.

Marine plywood vs typical plywood sheets

Water adds stress from every side.

General panels can swell and delaminate under long wet cycles.

marine grade plywood uses selected veneers and tougher glue.

BS1088 marine plywood adds tighter rules on cores and faces.

Use general plywood sheets for dry zones.

Use marine builds where rain, wash, or brine never rest.

ROCPLEX marine plywood value for trade buyers

We serve builders, yards, and fit-out shops across many lanes.

Your team needs steady supply and honest grades.

Quote with photos and spec sheets.

Pack hard and label clear.

ROCPLEX answer fast and keep dates real.

That is how jobs finish on time.

Core, face, and glue explained in simple steps

Core density controls screw pull and span.

Dense hardwood plywood cores hold fast and machine clean.

Poplar plywood cores save weight for lifts and small craft.

Faces vary by look and duty.

Pick clean faces for paint or clear finish.

Glue class sets service life.

Exterior bonds resist long wet cycles and heat.

Choose the lightest stack that meets the job.

Marine plywood in boats, façades, and formwork

Boat builders need tight curves and clean edges.

Thin plies bend well with steady grain.

Exterior façades face sun and rain each week.

Film or HPL skins add wear strength and easy cleaning.

Formwork crews chase repeat pours.

Film faces and sealed edges deliver smooth releases.

Size and thickness map for faster nests

1220 × 2440 plywood suits most yards and lines.

1250 × 2500 plywood fits Euro rigs and many CNC nests.

We also cut to size with kit labels.

Trims fall. Handling speeds up.

Your team gets more parts per shift.

Marine plywood cost factors you can control

Unit price is only the start.

Waste, rework, and delay cost more in the end.

Grades, cores, and glue add steps at the mill.

Packing, routes, and port rules add steps in transit.

ROCPLEX maps each step to a number.

You see where cash escapes and how to fix it.

Moisture, UV, and salt: how we fight them

Sun heats faces. Salt dries edges.

Seal edges to block wicking.

Match glue to duty and climate.

ROCPLEX train crews on storage and acclimation.

Those small habits protect faces and bonds.

Your panels work longer with less care.

Packaging that survives long lanes

We wrap tight and guard corners.

Top sheets shield faces from straps and rub.

Edge paint seals pores on all sides.

Bands cross both ways for firm holds.

Barcodes speed checks and claims.

Lift marks guide forks and reduce dents.

Marine plywood Compliance, tests, and documents

Many bids demand proof and speed.

We share bond tests, moisture logs, and core maps.

Chain-of-custody files travel by lot.

Emission classes appear on each report.

Country notes sit on the invoice where needed.

You pass checks without stress.

People also ask — quick answers

Is marine plywood waterproof?

No wood is fully waterproof.

marine plywood resists water with better veneers and glue.

Seal cuts and store well.

That mix handles long wet cycles.

Do I always need BS1088?

Not always.

Use BS1088 marine plywood when rules require it.

Use marine grade plywood for tough wet sites without strict audits.

Can I paint or laminate marine plywood?

Yes.

Sand right. Seal edges early.

Paint, film, or HPL all work well on clean faces.

How long will it last outside?

Life depends on design and care.

Seal edges. Vent back faces.

Follow fix and spacing rules.

Panels then run for many seasons.

What thickness should I pick?

Match span and load first.

12–15mm plywood suits many skins.

18–21mm plywood suits decks and floors.

Ask us for a quick span chart.

Storage and site handling

Keep stacks flat on level dunnage.

Cover tops and let air move around.

Avoid sun and wet floors during holds.

Acclimate before cutting.

Seal fresh cuts on site.

Simple steps save hours later.

ROCPLEX marine plywood production control

We track veneer lots and press codes by batch.

Supervisors log time, heat, and pressure in line.

QA teams cut witness strips and test bonds.

We hold back doubtful packs.

We share photos as runs progress.

You see your order build in real time.

freight, ports, and timing

Ocean rates move with seasons and space.

We book early and share shifts fast.

Free time rules differ by port.

We align routes with your lanes.

Mixed loads help small orders and trials.

Your boxes land ready to move.

Sustainable sourcing that helps bids

We source from known areas with legal cuts.

We reduce waste in layup and trim.

Offcuts feed energy or small parts.

Tight packs raise cubic use per box.

These steps help cost and the planet.

Marine plywood buyer checklist

- End use, climate, and exposure time.

- Face grade and patch rules.

- Core type and screw pull targets.

- Glue class and emission needs.

- Sizes, thickness, and tolerances.

- Packing style and labels.

- Route plan and free time rules.

- Tests and photos required.

Why ROCPLEX marine plywood wins repeat orders

Mix mill craft with trade sense.

Speak plain and move fast.

PWe protect time with smart prep.

ROCPLEX protect margin with lean plans.

That is our habit, not hype.

Marine plywood technical specs that matter

Moisture content shapes stability. We target 8–12% at ship time.

Local climate may differ. Plan short acclimation on site.

Thickness tolerance affects fit and yield. We hold tight bands.

Edges stay square after trimming and sanding.

Face grades guide both looks and price. We keep patch rules clear.

Panel density links to screw pull. Dense cores hold fasteners well.

Share pull targets. We match cores to those needs.

Marine plywood Spec table — quick reference

| Item | Target / Range | Why it matters | Field tip |

| Moisture | 8–12% | Controls movement | Acclimate before cuts |

| Thickness | Tight bands | Drives fit | Measure corners and center |

| Bond class | Exterior | Resists long wet cycles | Verify batch labels |

| Core gaps | Minimal | Stops edge leaks | Inspect witness strips |

| Face grade | Clean and tight | Smooth finish | Approve photo sets |

| Density | Consistent | Steady machining | Log screw pull tests |

Installation and sealing best practices

Seal every fresh cut. Do it the same day.

Use two light coats rather than one heavy coat.

Vent back faces where possible. Trapped moisture causes trouble.

Space fixings evenly. Maintain correct edge distances.

Stagger joints. Avoid long continuous seams.

Bed panels on clean, level frames.

Sweep grit away before closing skins.

Marine plywood coatings that last

Prep drives life. Sand with a clear grit path.

Raise the grain once. Sand back lightly.

Use primers that bond well on dense faces.

Topcoats must resist UV, heat, and spray.

Renew edges first during maintenance cycles.

Track hours since last service. Small logs help teams.

Adhesives and fasteners for wet duty

Choose crosslink PVA for stable rooms.

Pick polyurethane when moisture varies.

Use epoxy for mixed materials and tough joints.

Spread glue evenly. Starved joints fail early.

Clamp with moderate pressure. Heavy squeeze pushes glue out.

Use stainless or coated screws. Avoid rust streaks.

Pre-drill near edges to stop splits.

Design notes for curved parts

Thin plies bend well with steady grain.

Use heat or steam for tight radii.

Form curves with matched templates.

Let parts rest before final fix.

Seal kerfs and edges after bending.

Support curves during transport and storage.

Logistics, packing, and lanes

We wrap tight and guard corners.

Top sheets protect faces from straps.

Edge paint blocks moisture wicks.

Bands cross both ways for firm holds.

Barcodes speed checks and claims.

Lift marks guide forks and reduce dents.

We choose routes that fit your yard rules.

Storage and acclimation on site

Stack flat on level dunnage. Space sticks evenly.

Cover tops. Let air move around sides.

Keep stacks off wet floors and out of sun.

Acclimate before cutting. One or two days helps.

Seal new edges during install. That habit saves work.

Quality checks crews can run fast

Sight faces across light. Look for ripples.

Tap sheet centers. A dull note can flag gaps.

Measure thickness at four corners. Log readings.

Drive a sample screw near an edge. Feel the bite.

Cut a small strip and bend. Strong bonds resist splitting.

Record results. Photos help claims and audits.

Marine plywood use cases by sector

Boatbuilders need clean cores for tight curves.

Fit-out teams need flat faces and easy coats.

Facade crews need UV-tough skins and sealed edges.

Formwork teams need repeat pours and quick release.

Retail shops need hard skins that wipe clean.

Labs need stable, sealed surfaces with low emissions.

Marine Plywood Cost levers and total ownership

Unit price matters. Total cost matters more.

Trim loss, rework, and delay burn cash.

Choose sizes that match nests. Waste drops fast.

Pick the lightest core that still meets span.

Choose coatings by exposure and service cycle.

Plan lanes with port rules in mind.

Document everything. Proof shortens claims.

Marine plywood ROI mini model — size optimization

| Metric | Standard sheets | Smart sizes | Gain |

| Planned parts area | 1,000 m² | 1,000 m² | — |

| Yield after trim | 85% | 92% | +7 pts |

| Sheets required | 1,176 m² | 1,087 m² | −89 m² |

| Labor cuts | — | Fewer trims | Save hours |

People also ask — advanced answers

Can I use it for bathrooms and spas?

Yes, with care. Seal edges well.

Vent rooms. Maintain joints on a schedule.

Will coatings stop all water?

No coating stops every path.

Good design and sealing do the rest.

How do I stop end-grain wicking?

Round edges lightly.

Seal with multiple light coats.

Can I bond skins to metals?

Yes. Use epoxy systems.

Scuff and clean the metal first.

What fixings suit salt zones?

Use 316 stainless where salt lingers.

Rinse hardware during service.

Marine Plywood Testing and certification kit

We share bond, MOR, and moisture tests.

Batch codes trace to veneer lots.

Chain-of-custody files travel with invoices.

Emission classes appear on each report.

Photos document cores and faces.

Audits finish faster with clear files.

Comparison with other Plywood panel families

plywood sheets cover many dry zones well.

General wood panels suit stable rooms and light loads.

Solid timber stiffens frames and edges.

Use each material where it shines.

We help teams mix systems with less risk.

Marine plywood for facade systems

Back-vent skins. Keep drainage paths open.

Isolate metals to prevent stains.

Use flexible sealants at joints.

Detail drip edges to shed water.

Service schedules keep looks fresh.

Marine plywood for formwork

Pick film faces for quick release.

Seal edges after every trim.

Use clean oils as the supplier advises.

Rotate packs to balance wear.

Track pours by pack number.

Replace damaged pieces before blowouts.

Marine plywood for small craft

Choose lighter cores for easy lifts.

Add stringers where spans grow.

Seal lockers and edges first.

Use non-skid topcoats on decks.

Check fasteners after first sea trials.

Buyer checklist — print and use

- End use, climate, and exposure time.

- Face grade and patch rules.

- Core type and pull targets.

- Bond class and emission needs.

- Sizes, thickness, and tolerances.

- Coatings and edge-seal system.

- Packing style and barcode rules.

- Route plan, ports, and free time.

- Tests, photos, and batch codes.

Target ship week and split options.

ROCPLEX marine plywood service bundle

We confirm specs in plain words.

Our planners block mill time for repeats.

We send live photos from the floor.

Labels and pack maps ship ahead.

ETDs update early and clearly.

Claims stay rare and resolve fast.

BS1088 Certified Marine Plywood

ROCPLEX 18mm Marine Plywood sheets with waterproof WBP bonding and smooth hardwood veneers provide high strength, moisture resistance, and long-term durability, ideal for boat building, dock construction, wet-area cabinetry, and exterior marine applications.

Final message to trade buyers

Wet work punishes weak stacks.

Choose panels built for water and time.

We build, pack, and ship with care.

Your teams deliver neat work without drama.

Ask for samples and a span chart today.

Let ROCPLEX guide your next order with calm detail.

Combi plywood

What is Combi Plywood?

Combi plywood is a board built by combining hardwood veneers with softwood layers. The hardwood provides strength, while the softwood lowers weight and cost. Each layer is cross-bonded, which increases stability and reduces swelling. Compared with full hardwood plywood, this panel offers a balance of performance and price. Combi plywood sheets come in different grades, thicknesses, and surface finishes. Builders use them for walls, floors, and formwork. Furniture makers apply them in cabinets and shelves. With wide applications and fair cost, combi plywood remains a smart choice for global buyers.

Key Benefits of Combi Plywood

Combination core plywood gives reliable strength. The hardwood layers increase durability, while the softwood keeps it light.

The panel resists bending and holds shape well. This ensures safe use in both dry and humid spaces.

It offers a smooth surface for laminates, veneers, or paint. As a result, it adapts to many design styles.

Combi plywood price is usually lower than full hardwood panels. Therefore, wholesalers and buyers find it more affordable.

Applications in Furniture and Construction

Furniture makers use combination core plywood for cabinets, shelves, and wardrobes. It is easy to cut, drill, and finish.

Builders use it for flooring, wall sheathing, and roofing. In these roles, it performs reliably under load.

Interior designers value its flexibility. For example, combination core plywood accepts high-end veneers for decorative panels.

Packaging companies also use it for crates and pallets. The light weight reduces freight costs while keeping goods safe.

Combi Plywood in Global Trade

Combi plywood suppliers serve both local and export markets. Bulk shipments support stable supply for wholesalers.

Custom packing and clear labeling improve efficiency in logistics. This allows fast handling at ports and warehouses.

The rising demand for affordable wood panels keeps combi plywood wholesale orders steady. Buyers trust it for cost and quality.

Why Work with Trusted Combi Plywood Suppliers

Professional suppliers test every sheet before shipment. They check bonding, moisture, and surface smoothness.

In addition, they offer certificates for quality and eco-friendly sourcing. This builds trust with global buyers.

Suppliers also support wholesalers with advice on grades, thickness, and applications. This helps reduce mistakes and saves cost.

Factors Affecting Combi Plywood Price

Species of hardwood used in the face layers affects the cost. Premium veneers add beauty but raise price.

Panel thickness influences price. Thicker sheets need more material and increase cost.

Freight distance and shipping conditions also change the final price. Reliable suppliers manage logistics for stable costs.

Value for Furniture Makers

Furniture producers prefer combination core plywood for its mix of strength and light weight. It reduces waste and speeds up work.

The panel holds screws well, making it ideal for joints. This ensures furniture lasts longer.

It also accepts a wide range of finishes. Therefore, designers can meet both modern and classic styles.

Choosing the Right Combi Plywood Sheets

Buyers should choose thickness and grade based on use. Thin panels suit drawers, while thicker ones suit floors.

Moisture-resistant grades are best for kitchens or bathrooms. Standard grades perform well in living spaces.

Suppliers guide buyers in selecting the right sheet. As a result, projects stay within budget and quality targets.

Wholesale Solutions for Global Buyers

Large buyers prefer combi plywood wholesale shipments. Bulk supply keeps costs low and stock reliable.

Suppliers offer flexible shipping schedules, helping buyers manage supply chains.

Demand for this product grows worldwide. Trusted suppliers focus on steady quality and customer support.

Value of ROCPLEX Combi Plywood for Buyers and Builders

ROCPLEX combi plywood gives buyers the right balance between performance and price. It supports strong furniture, reliable construction, and smooth finishes.

Our brand ensures consistent supply, while competitive combi plywood price keeps it affordable for wholesalers. As a result, ROCPLEX remains a trusted name in global wood products.

Edge Form LVL – SENSOedge

SENSO Edge Form LVL is engineered for concrete slab formwork, offering high strength, straightness, and durability. As a reliable edge form supplier, SENSO ensures precise LVL boards ideal for professional formwork applications.

Post time: Sep-15-2025