Melamine Faced Block Board

ROCPLEX Melamine Faced Block Board

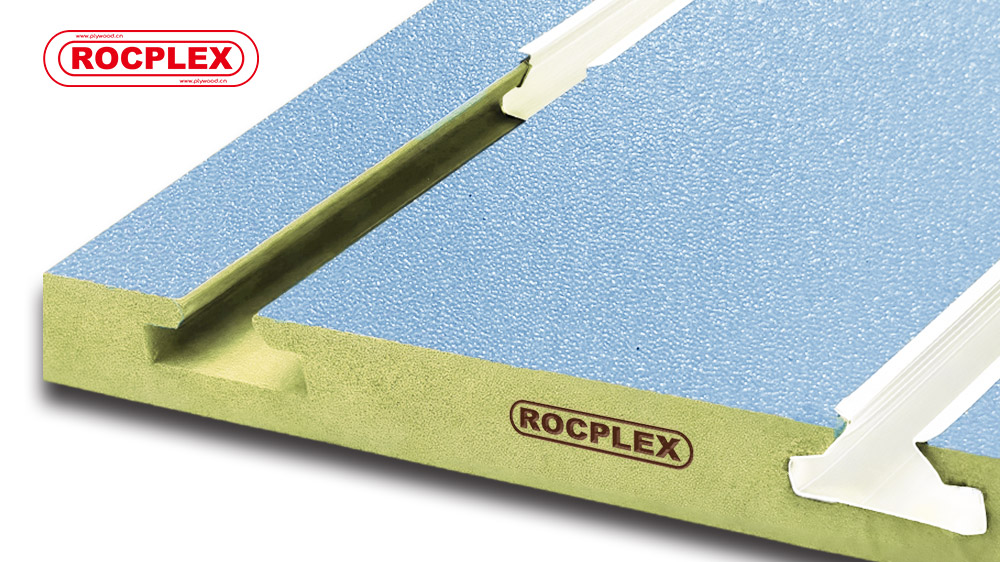

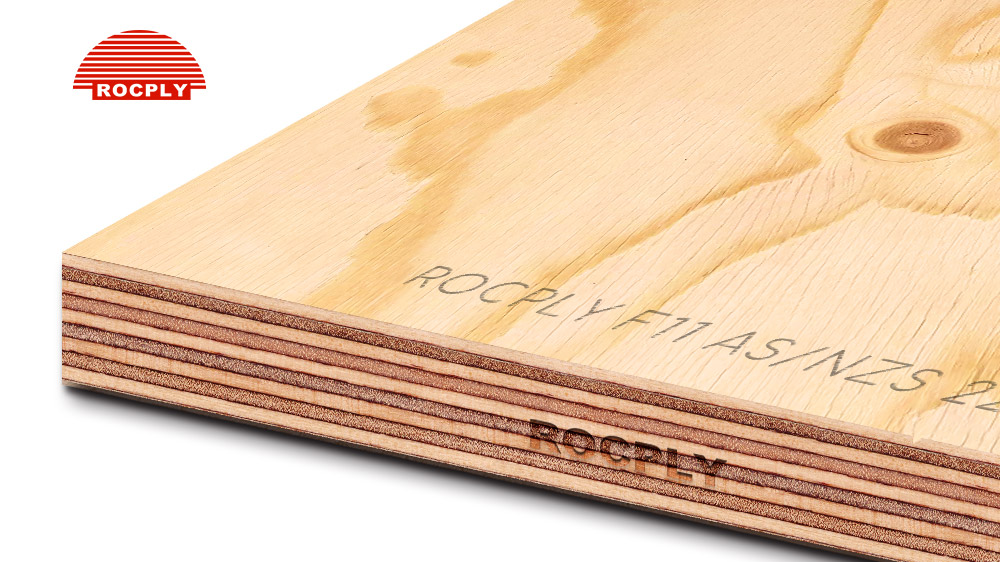

ROCPLEX melamine faced block board combines strength with a decorative surface for quality interior applications. It uses solid wood blocks as its core, arranged edge-to-edge and sandwiched between layers of veneer. This structure offers superior load-bearing performance and dimensional stability.

The melamine layer is thermally bonded under pressure, creating a surface that is scratch-resistant, water-repellent, and easy to clean. The board maintains a consistent appearance and uniform texture, suitable for visible surfaces in cabinetry or paneling.

Due to the block core structure, the panel exhibits excellent screw retention, even at the edges. This makes it a preferred choice for carpenters and cabinetmakers working on modular furniture or built-in wardrobes.

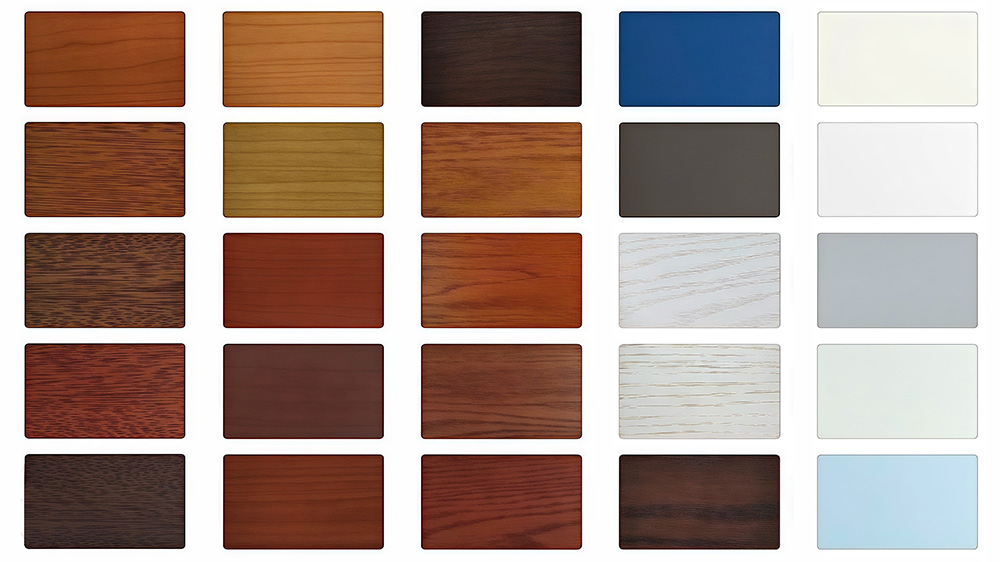

The product is available in single or double-sided melamine coating. Customers can choose from matte, textured, or gloss finishes. ROCPLEX offers customization in terms of colors and edge banding to match various styles and functions.

The production process follows strict quality control. Each sheet is calibrated for thickness accuracy and surface quality, ensuring compatibility with modern cutting and edging machines.

>>>

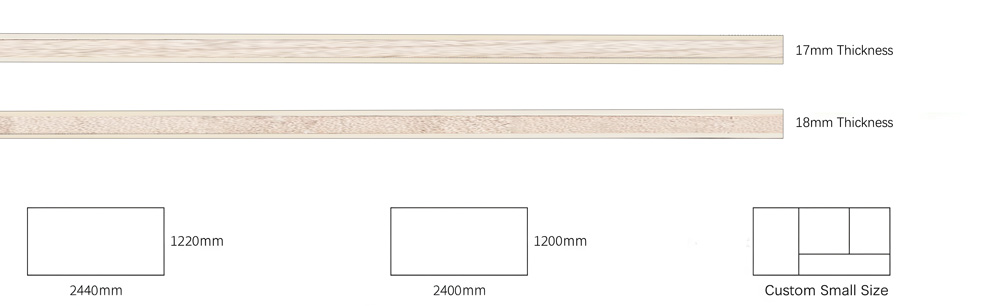

ROCPLEX Melamine Faced Block Board Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 17 | 2440 | 1220 | Melamine | AA |

| 18 | 2440 | 1220 | Melamine | AA |

>>>

ROCPLEX Melamine Faced Block Board Patterns and Colors

>>>

ROCPLEX Melamine Faced Block Board Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | G2S | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | / | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 E1 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 480-550 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX melamine board is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX Melamine Faced Block Board Features & Benefits

- Strong Solid Wood Core

- Engineered with edge-glued wood strips, the core delivers rigidity, making it suitable for heavy-duty furniture.

- Smooth Melamine Surface

- The laminated surface is available in diverse finishes, offering aesthetic versatility and scratch resistance.

- Excellent Machinability

- ROCPLEX block board allows clean cutting, drilling, and shaping, ideal for CNC or manual woodworking.

- Stable and Low Warping

- Balanced construction ensures dimensional stability and minimizes the risk of bending or surface irregularities.

- High Screw Holding Strength

- The dense core structure holds screws firmly, ideal for hinges, brackets, and hardware mounting.

- Custom Sizes and Colors

- ROCPLEX supports tailored dimensions, surface styles, and decorative options for diverse furniture design needs.

>>>

ROCPLEX Melamine Faced Block Board Certified By

|  |  |  |

ROCPLEX melamine faced block board is widely used in furniture manufacturing. It is ideal for wardrobe carcasses, bookcases, and desks.

It performs well in residential or office interior partitions, offering both form and function. The board is also suitable for shelving and panel walls.

Due to its clean surface and strength, it is preferred for modular kitchens, bathroom vanities, and school or hospital furniture.

Its adaptability makes it valuable for shopfitting, commercial counters, and interior wall lining systems.

ROCPLEX melamine faced block board provides the strength of solid timber with the surface of modern laminates. Whether you’re building wardrobes, partitions, or retail fixtures, this panel ensures performance and style. For design flexibility and structural integrity in one board, Contact ROCPLEX today to request a quote or consultation.

>>>

ROCPLEX Melamine Faced Block Board FAQ

Q: What is melamine faced block board?

A: Melamine faced block board is a wood panel made from a solid wood core and laminated with melamine-impregnated decorative paper on both sides. ROCPLEX melamine faced block board offers durability, strength, and an attractive surface suitable for interior applications.

Q: What colors and finishes can I choose?

A: ROCPLEX offers a wide range of melamine finishes, including matte, high gloss, wood grain, and textured surfaces. Custom colors and patterns can be matched to your project needs.

Q: Is this board suitable for furniture?

A: Yes. ROCPLEX melamine faced block board is ideal for wardrobes, bookcases, shelves, partitions, desks, and other indoor furniture. Its solid core provides strength and stability, while the melamine surface enhances aesthetics and wear resistance.

Q: Can ROCPLEX melamine faced MDF be used for kitchen furniture?

A: Absolutely. It’s a popular material for kitchen cabinets, pantry shelving, and closet doors due to its durability and surface finish.

Q: Can ROCPLEX provide edge banding and CNC cutting?

A: Yes. ROCPLEX offers value-added services such as edge banding, custom sizing, and CNC machining to fit your production or project requirements.