Melamine Faced Chipboard

ROCPLEX Melamine Faced Chipboard

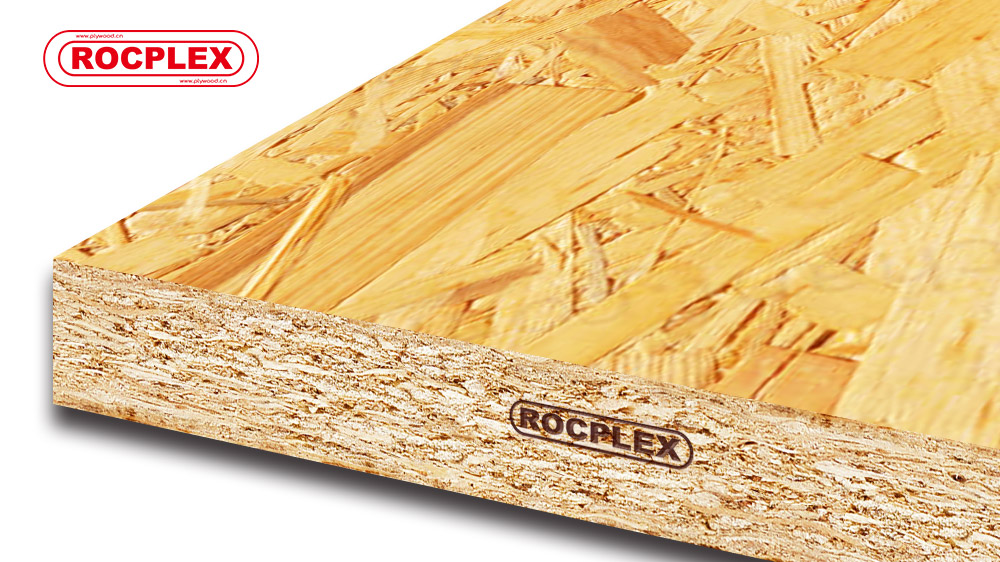

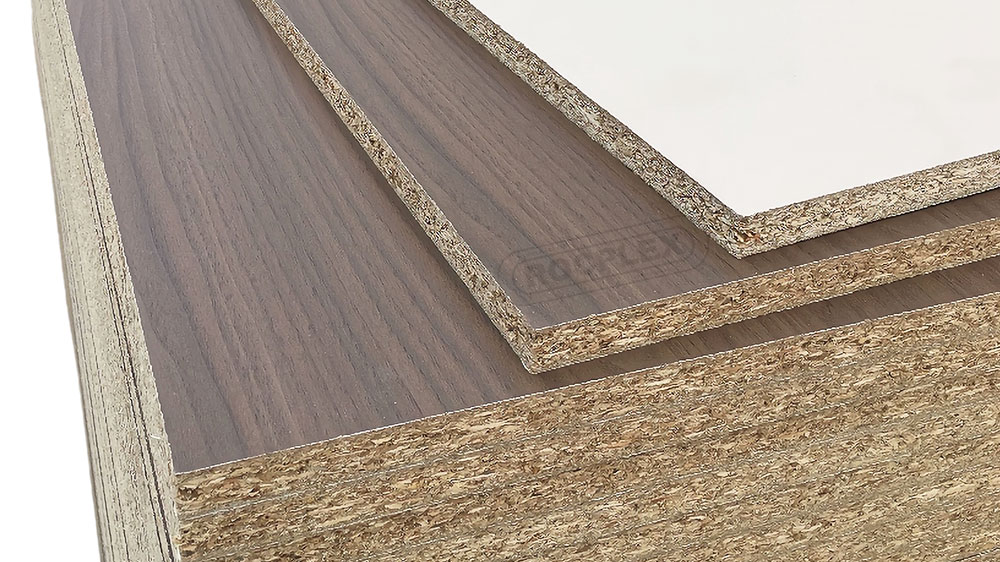

ROCPLEX melamine faced chipboard is produced by bonding a decorative melamine film onto high-quality particle board under high pressure and heat. This surface layer delivers enhanced durability, abrasion resistance, and aesthetic appeal in one panel.

The core is made of refined wood particles pressed into a dense and stable board. This structure offers excellent screw-holding capacity and dimensional stability. It is ideal for precision cutting, edge banding, and lamination.

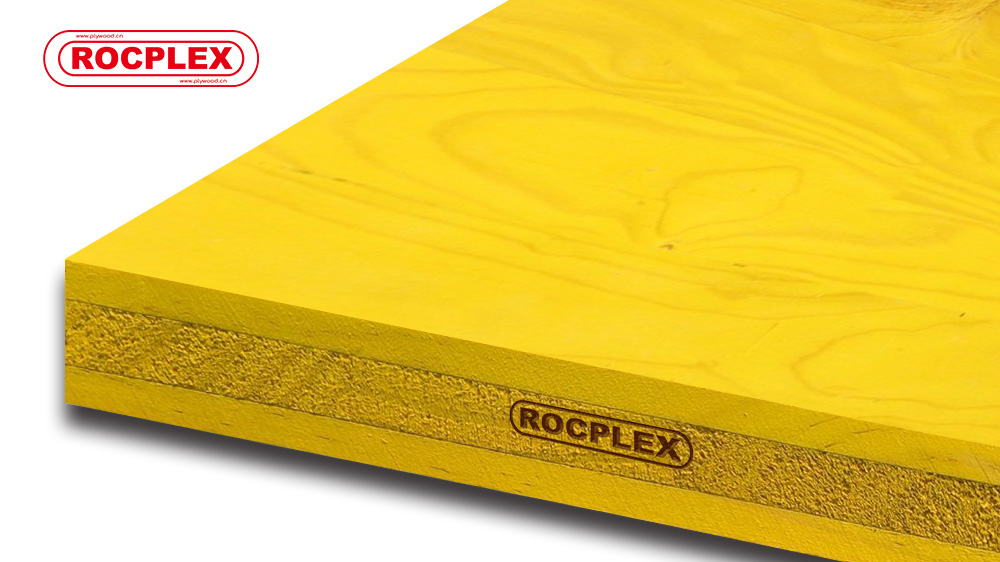

The melamine layer comes in various textures, including wood grain, solid colors, and abstract patterns. It provides a clean, modern finish that resists discoloration, impact, and light moisture. The surface is non-porous and easy to maintain.

ROCPLEX’s production ensures even density throughout the panel. Each board undergoes strict quality control to maintain surface consistency and structural integrity. It meets E1 or E0 formaldehyde emission standards for indoor use.

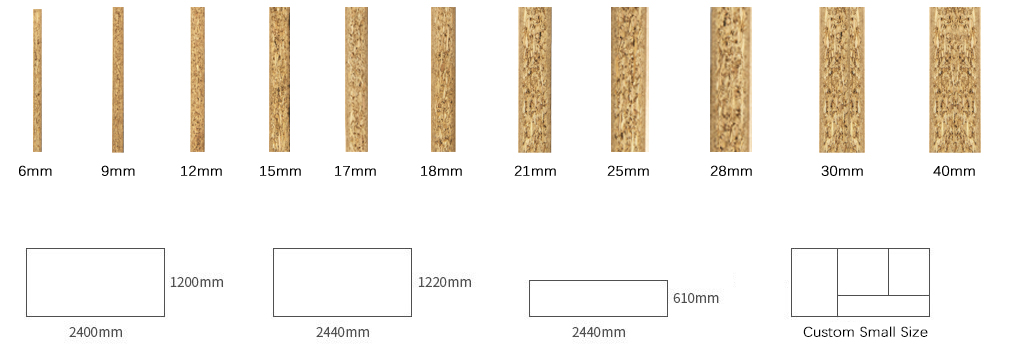

Available in multiple sizes and thicknesses, ROCPLEX melamine faced chipboard supports custom design and fabrication for retail, hospitality, and residential furniture markets.

>>>

ROCPLEX Melamine Faced Chipboard Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 6 | 2440 | 1220 | Melamine | AA |

| 9 | 2440 | 1220 | Melamine | AA |

| 12 | 2440 | 1220 | Melamine | AA |

| 15 | 2440 | 1220 | Melamine | AA |

| 17 | 2440 | 1220 | Melamine | AA |

| 18 | 2440 | 1220 | Melamine | AA |

| 21 | 2440 | 1220 | Melamine | AA |

| 25 | 2440 | 1220 | Melamine | AA |

| 30 | 2440 | 1220 | Melamine | AA |

| 40 | 2440 | 1220 | Melamine | AA |

>>>

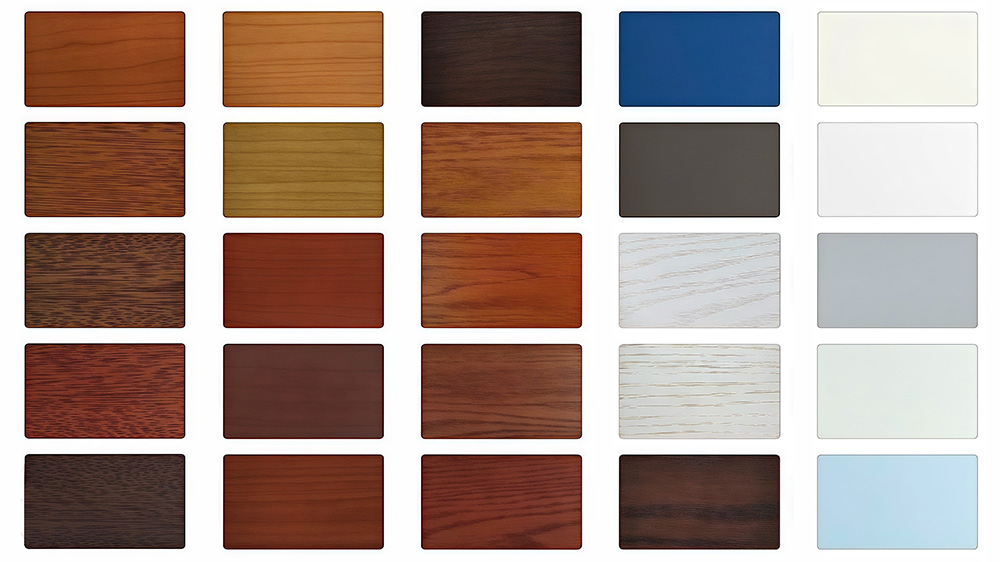

ROCPLEX Melamine Faced Chipboard Patterns and Colors

>>>

ROCPLEX Melamine Faced Chipboard Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | G2S | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | / | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 E1 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 650-720 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX melamine board is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX Melamine Faced Chipboard Features & Benefits

- Durable Melamine Surface

- The melamine finish resists daily wear and tear, scratches, and moisture from normal indoor use.

- Decorative Options Available

- ROCPLEX offers a wide range of textures and patterns to match contemporary design trends and project branding.

- Stable Core Structure

- The dense chipboard core ensures high screw retention and dimensional stability, ideal for long-term furniture use.

- Eco-Friendly and Low Emission

- Panels comply with E0 or E1 emission ratings, making them suitable for enclosed spaces with health requirements.

- Ease of Machining and Fabrication

- ROCPLEX boards are compatible with standard cutting and drilling equipment, ensuring smooth production flow.

- Cost-Effective Material

- Compared to solid wood or plywood, melamine faced chipboard offers a budget-friendly solution without compromising on appearance.

>>>

ROCPLEX Melamine Faced Chipboard Certified By

|  |  |  |

ROCPLEX melamine faced chipboard is widely used in ready-to-assemble furniture. It supports CNC routing and clean edge banding for cabinet doors, wardrobes, and shelving units.

In office furniture, this board offers a durable, stylish finish for desks, partitions, and storage modules. Its surface resists wear in high-use environments.

Retail interiors benefit from the customizable look of ROCPLEX chipboard. It is ideal for counters, display fixtures, and wall panels.

The board is also used in modular kitchens, offering cost-efficient surfaces for cabinetry and drawer units that maintain their appearance over time.

Looking for premium melamine faced chipboard for furniture or interior projects? ROCPLEX delivers reliable, stylish, and durable panels tailored to your production needs. Contact ROCPLEX today for bulk pricing, samples, or custom solutions for your business.

>>>

ROCPLEX Melamine Faced Chipboard FAQ

Q: What is melamine faced chipboard?

A: Melamine faced chipboard is a type of particle board laminated with a melamine resin-impregnated paper. It offers a decorative surface that is durable, scratch-resistant, and easy to clean, ideal for furniture and interior paneling.

Q: What sizes and thicknesses are available?

A:ROCPLEX melamine faced chipboard is available in standard sizes like 1220mm x 2440mm and thicknesses ranging from 9mm to 25mm. Custom dimensions can be arranged upon request.

Q: Can ROCPLEX melamine chipboard be cut and edged easily?

A: Yes. ROCPLEX panels are made from high-density chipboard that supports smooth cutting, CNC machining, and edge banding without chipping or breaking.

Q: What surface textures and colors are available?

A: ROCPLEX offers a wide range of finishes, including wood grain, matte, gloss, and solid colors. Custom colors and textures can also be produced based on project needs.

Q: What is the difference between melamine chipboard and melamine MDF?

A: Both have melamine surfaces, but MDF has a finer core that offers better edge finishing and strength. Chipboard is more economical and lighter.