OSB Board (Oriented Strand Board)

ROCPLEX OSB Board

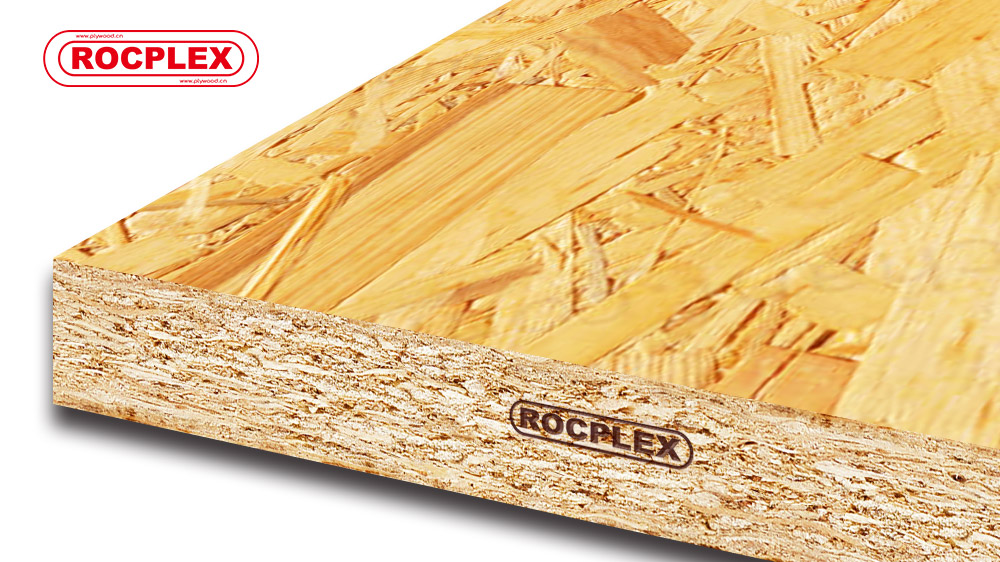

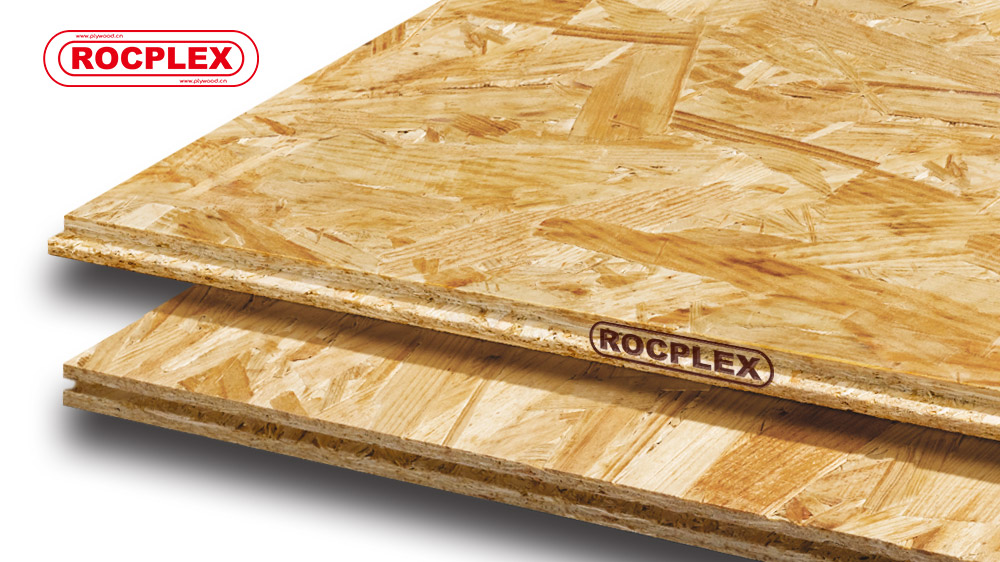

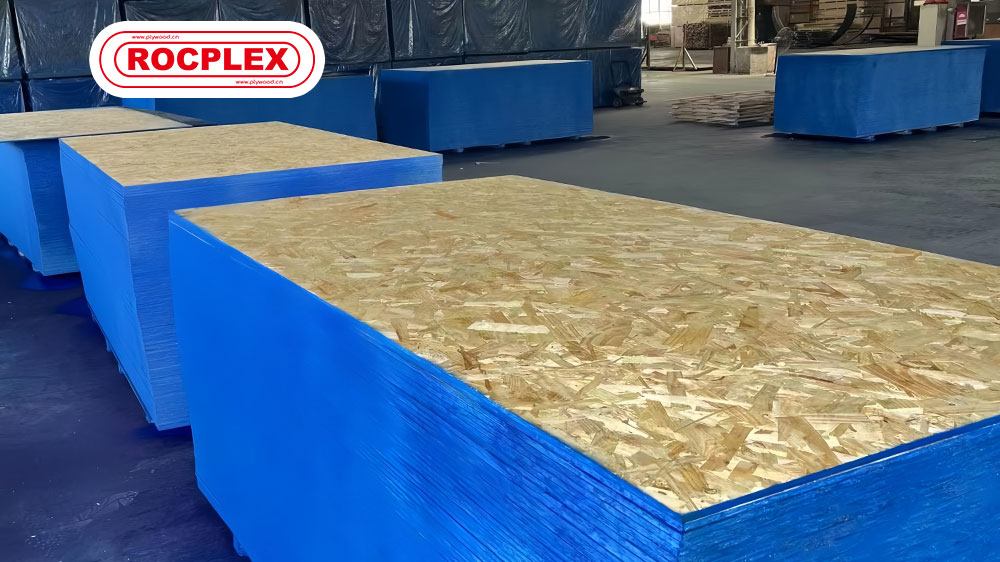

ROCPLEX OSB Board is a high-performance panel manufactured from precisely engineered wood strands arranged in layers for maximum strength. The board is hot-pressed and bonded with moisture-resistant adhesives, making it ideal for both structural and non-structural applications.

Unlike conventional plywood, ROCPLEX OSB Board provides uniform density across the panel. The cross-layered strand orientation delivers high load-bearing capacity and resistance to bending, splitting, and swelling. This performance advantage makes it a preferred material in modern framing and decking systems.

ROCPLEX OSB is manufactured under strict quality control standards to ensure flatness, squareness, and consistent thickness. Available in a variety of thicknesses and sizes, it suits a wide range of requirements in the construction and furniture industries.

Depending on the intended use, ROCPLEX OSB is available in OSB2 (for dry conditions), OSB3 (for humid environments), and OSB4 (for heavy-duty structural uses). Each type meets international building codes and environmental compliance standards.

>>>

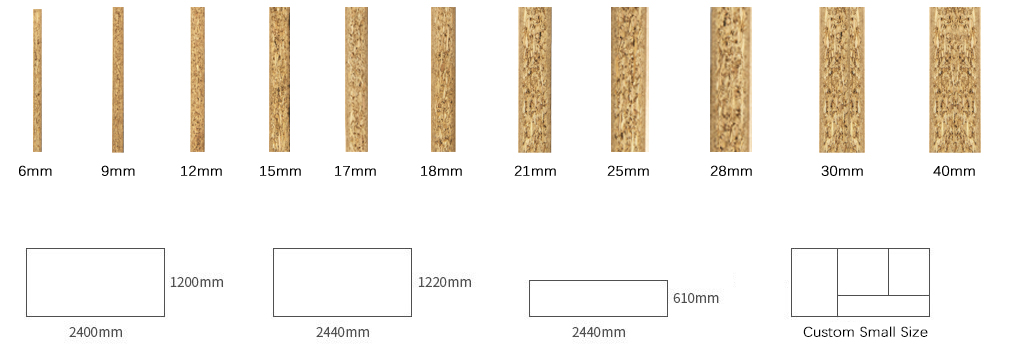

ROCPLEX OSB Board Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 6 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 9 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 12 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 15 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 17 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 18 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 21 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 25 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 30 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

| 40 | 2440 | 1220 | OSB2 OSB3 OSB4 | AA |

>>>

ROCPLEX OSB Board Type

Oriented Strand Board (OSB) is typically manufactured from pine, poplar, spruce, and Douglas fir. These timber species are widely used due to their availability, rapid growth, and reliable structural characteristics, making them well-suited for OSB production.

>>>

ROCPLEX OSB Board Grade

OSB is graded based on its strength and moisture resistance, in line with standards like EN 300 in Europe or APA/PS 2 in North America. The main grades include OSB1, OSB2, OSB3, and OSB4.

OSB1

OSB1 is suitable for non-structural, interior use in dry conditions. Ideal for furniture, packaging, and general decorative applications.

OSB2

OSB2 is designed for load-bearing applications in dry environments. Commonly used in furniture frames, shelving, and subflooring.

OSB3

OSB3 is a moisture-resistant, structural board ideal for load-bearing use in humid conditions such as wall sheathing, flooring, and roofing.

OSB4

OSB4 is a high-performance structural panel with enhanced strength and moisture resistance, used in demanding construction and industrial settings.

>>>

ROCPLEX OSB Board Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | G2S | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | / | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 E1 E2 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 650 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX OSB board is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX OSB Board Features & Benefits

- Structural Strength:

- Engineered strand alignment ensures high load-bearing capacity and uniform strength.

- Moisture Resistance

- OSB3 and OSB4 grades provide superior resistance in humid environments and temporary exposure to moisture.

- Dimensional Stability

- Maintains shape and size under changing weather conditions without warping or cracking.

- Eco-Friendly Composition

- Made from fast-growing plantation wood using minimal waste and formaldehyde-compliant adhesives.

- Cost Efficiency

- Delivers outstanding performance at a more economical price than traditional plywood.

- Versatility:

- Suitable for floors, roofs, walls, packaging, and industrial usage across multiple climate zones.

>>>

ROCPLEX OSB Board Certified By

|  |  |  |

ROCPLEX OSB Board is widely used in structural flooring, subfloor systems, and wall sheathing. Its consistent strength makes it suitable for heavy-duty roof decking as well.

The panel is also commonly applied in packaging, modular homes, industrial racking systems, and crates due to its impact resistance and structural integrity.

For residential and commercial construction, ROCPLEX OSB Board provides reliable performance in both vertical and horizontal applications.

Thanks to its moisture resistance and durability, it is an effective alternative to plywood in many regions with varying humidity conditions.

Enhance your project with reliable and strong ROCPLEX OSB Board. Whether you’re building floors, roofs, or wall systems, ROCPLEX delivers unmatched quality. Contact ROCPLEX sales team today to discuss specifications, volume discounts, and shipping solutions tailored to your business.

>>>

ROCPLEX OSB Board FAQ

Q: What is OSB Board?

A: OSB Board (Oriented Strand Board) is an engineered wood panel made from wood strands arranged in layers and bonded with adhesives. ROCPLEX OSB is designed for structural use in flooring, roofing, and wall sheathing.

Q: What are the differences between OSB2, OSB3, and OSB4?

A: OSB2 is used in dry conditions for general construction.

OSB3 is moisture-resistant and suitable for humid areas.

OSB4 is heavy-duty and engineered for high load-bearing structural applications.

Q: Can ROCPLEX OSB be used as subflooring?

A: Yes. ROCPLEX OSB Board provides high dimensional stability and load-bearing capacity, making it ideal for subflooring in residential and commercial buildings.

Q: Is ROCPLEX OSB Board suitable for roofing?

A: Yes. ROCPLEX OSB3 and OSB4 grades are widely used for roof decking, offering strength, resistance to sagging, and a smooth nailing surface for shingles and membranes.

Q: Can OSB be painted or coated?

A: Yes. ROCPLEX OSB has a smooth surface that allows for painting, coating, or laminating as needed for aesthetic or protective purposes.