Poplar Plywood

ROCPLEX Poplar Plywood

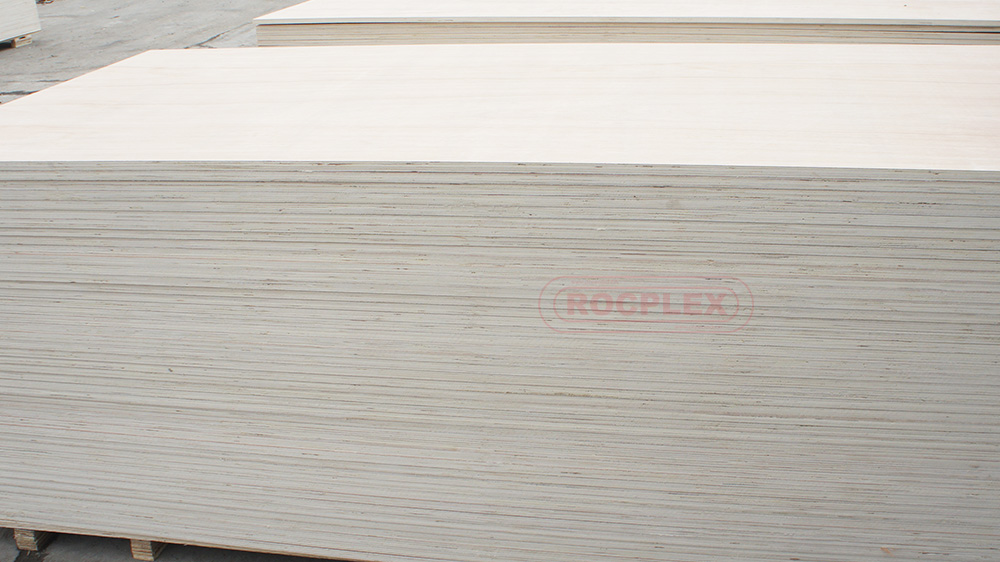

ROCPLEX Poplar Hardwood Plywood is made using plantation-grown poplar veneers bonded with durable, formaldehyde-compliant adhesives. Each sheet is hot-pressed under strict controls to ensure flatness, strength, and dimensional stability.

This plywood features a soft yet stable core structure. The outer veneers are sanded for a smooth finish, allowing direct application of laminates, paints, or decorative overlays. The internal layers are tightly bonded, minimizing gaps and improving performance in fabrication

Its lightweight nature makes it easy to handle and transport. This is especially useful for furniture manufacturers and interior contractors requiring materials that offer both flexibility and strength.

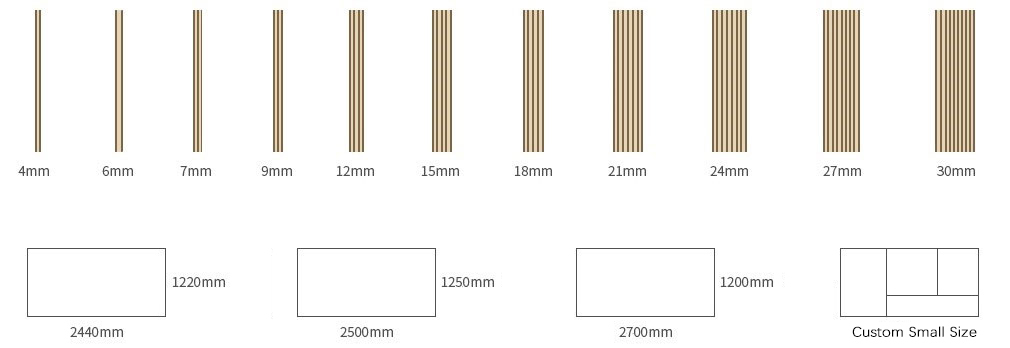

ROCPLEX Poplar Plywood is available in a range of sizes and thicknesses. It complies with international production and environmental standards. The plywood is inspected at each stage to meet export-grade quality for global distribution.

Whether for household interiors, packaging solutions, or display systems, ROCPLEX ensures a reliable plywood solution with a smooth surface and strong core structure.

>>>

ROCPLEX Poplar Plywood Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Poplar | AA |

| 7 | 2440 | 1220 | Poplar | AA |

| 9 | 2440 | 1220 | Poplar | AA |

| 12 | 2440 | 1220 | Poplar | AA |

| 15 | 2440 | 1220 | Poplar | AA |

| 17 | 2440 | 1220 | Poplar | AA |

| 18 | 2440 | 1220 | Poplar | AA |

| 19 | 2440 | 1220 | Poplar | AA |

| 25 | 2440 | 1220 | Poplar | AA |

| 28 | 2440 | 1220 | Poplar | AA |

>>>

ROCPLEX Poplar Plywood

>>>

ROCPLEX Poplar Plywood Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | G2S | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | A Bond | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E1 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 530-580 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX Poplar Plywood Features & Benefits

- Lightweight Yet Strong

- Easier to lift, install, and transport compared to heavier hardwood alternatives, without sacrificing strength.

- Smooth and Uniform Surface

- Sanded outer layers offer an excellent base for veneer, laminate, or direct finishing.

- Stable Internal Bonding

- Well-composed inner veneers reduce internal gaps and maintain shape during processing.

- Versatile in Use

- Suitable for furniture, packaging, carpentry, and decorative construction.

- Easy to Process

- Supports manual and automated cutting, sanding, and finishing with minimal wear on tools.

- Cost-Effective Material

- Offers economic value for manufacturers seeking a balance between quality and affordability.

>>>

ROCPLEX Poplar Plywood Certified By

|  |  |  |

ROCPLEX Poplar Plywood is widely used in indoor furniture, particularly in drawer backs, cabinet bodies, and table undersides.

It is a preferred material for interior paneling and ceiling frameworks, thanks to its light weight and finish quality.

The board is also suitable for packaging boxes and transport crates where durability and weight savings are essential.

For DIY users and professionals alike, this plywood supports clean cuts, efficient handling, and stable structural performance.

Looking for a durable yet lightweight plywood for furniture or interior use? Contact ROCPLEX today to secure Poplar Plywood tailored for your production needs.

>>>

ROCPLEX Poplar Plywood FAQ

Q: What is Poplar Plywood?

A: Poplar Plywood is a panel made entirely or mainly from poplar veneers. It is lightweight, smooth, and easy to work with.

Q: What are the benefits of using poplar as the core material?

A: Poplar offers a balance between low weight and moderate strength. It is ideal for furniture, packaging, and interior paneling.

Q: How does ROCPLEX Poplar Plywood compare to eucalyptus or birch plywood?

A: While eucalyptus and birch are denser, poplar is lighter, more affordable, and easier to handle for less demanding structural use.

Q: Is poplar plywood suitable for laminating and veneering?

A: Yes. The surface is sanded and uniform, making it ideal for decorative overlays, melamine paper, or thin veneer application.

Q: What are the available thicknesses and dimensions?

A: ROCPLEX Poplar Plywood is offered in thicknesses from 3mm to 25mm. Common sizes include 1220x2440mm, with custom options available.