PP Plastic Plywood

ROCPLEX PP Plastic Plywood

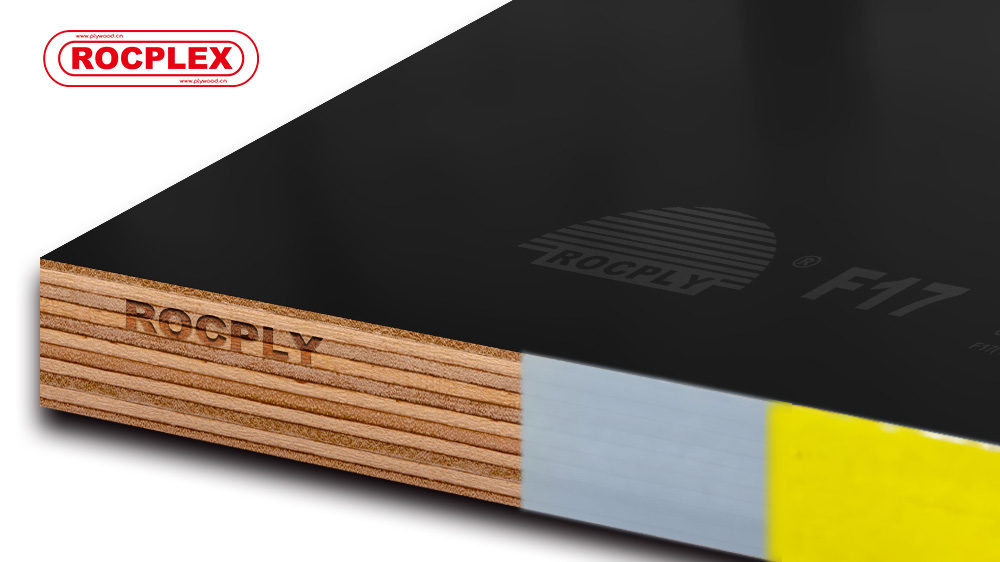

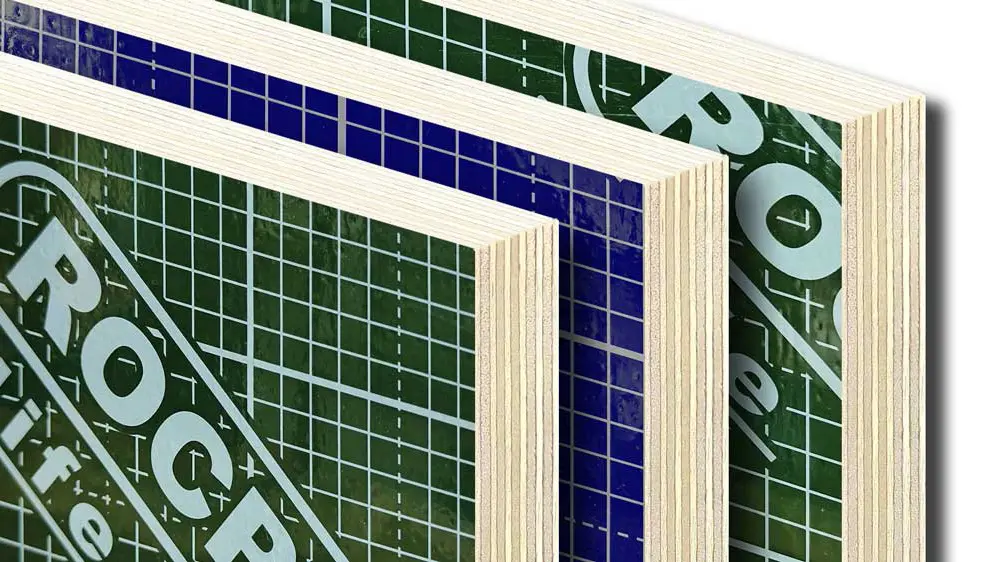

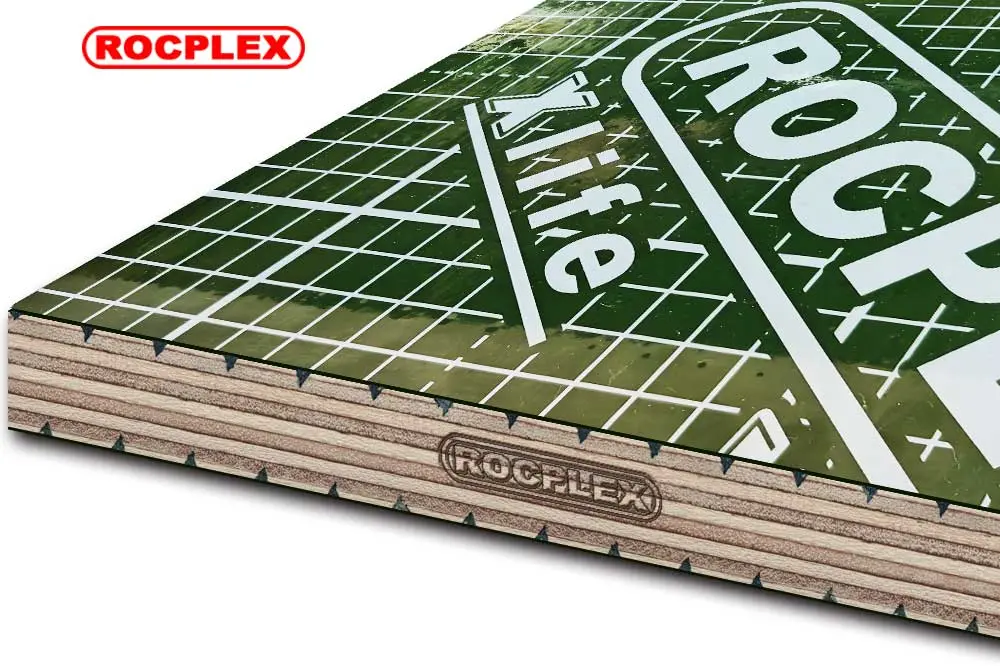

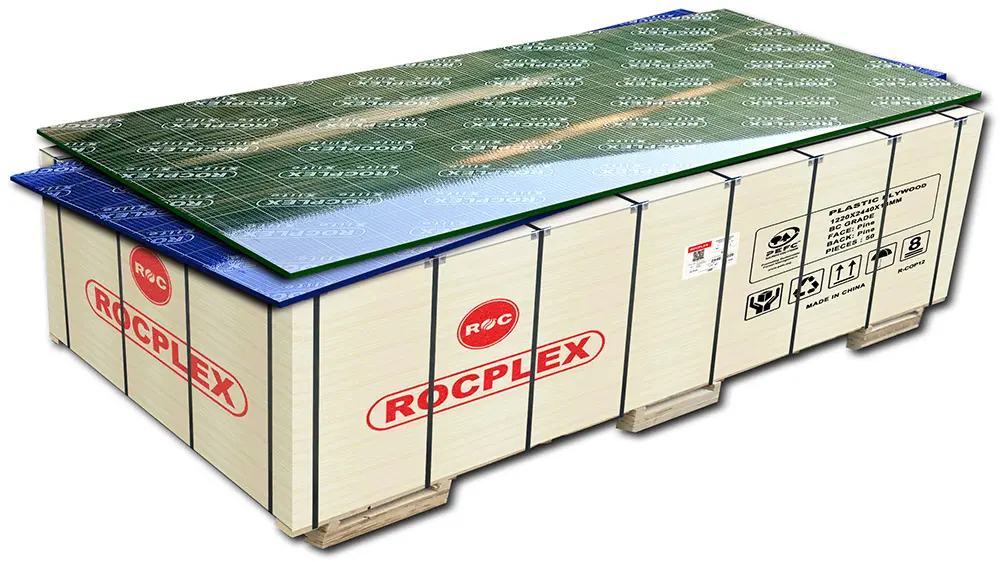

ROCPLEX PP Plastic Faced Plywood stands out with its robust and waterproof characteristics, making it an essential material for demanding construction projects. The plastic coating on the plywood surface not only provides enhanced durability but also ensures excellent resistance to moisture, extending the lifespan of the material. This makes PP Plastic Coated Plywood a reliable choice for both indoor and outdoor applications.

ROCPLEX PP Plastic Faced Plywood panel is versatile and suitable for various applications, including formwork, flooring, and walls. Its superior strength and moisture resistance make it particularly useful in areas prone to dampness and heavy use. Builders and contractors appreciate the ease of handling and installation that comes with using our Plastic Plywood.

ROCPLEX PP Plastic Faced Plywood panel is versatile and suitable for various applications, including formwork, flooring, and walls. Its superior strength and moisture resistance make it particularly useful in areas prone to dampness and heavy use. Builders and contractors appreciate the ease of handling and installation that comes with using our Plastic Plywood.

In terms of sustainability, ROCPLEX ensures that our PP plastic coated plywood sheets is produced with eco-friendly practices, minimizing environmental impact. This commitment to quality and sustainability makes our product a preferred choice in the construction industry.

>>>

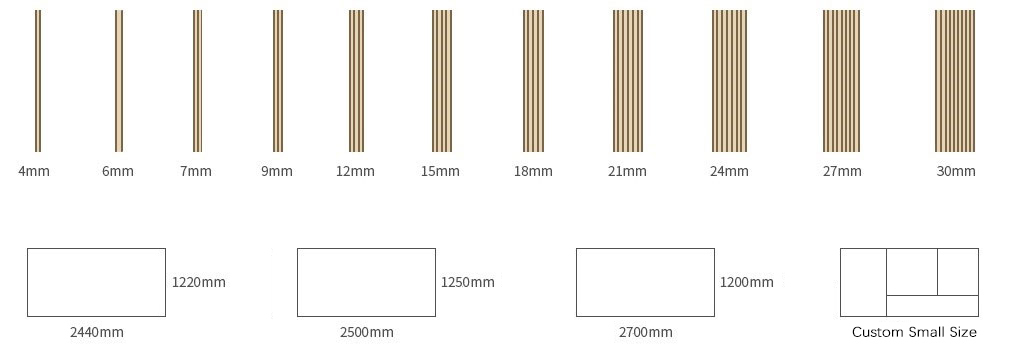

ROCPLEX PP Plastic Plywood Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Birch / Hardwood | AA |

| 7 | 2440 | 1220 | Birch / Hardwood | AA |

| 9 | 2440 | 1220 | Birch / Hardwood | AA |

| 12 | 2440 | 1220 | Birch / Hardwood | AA |

| 15 | 2440 | 1220 | Birch / Hardwood | AA |

| 17 | 2440 | 1220 | Birch / Hardwood | AA |

| 18 | 2440 | 1220 | Birch / Hardwood | AA |

| 19 | 2440 | 1220 | Birch / Hardwood | AA |

| 25 | 2440 | 1220 | Birch / Hardwood | AA |

| 28 | 2440 | 1220 | Birch / Hardwood | AA |

>>>

ROCPLEX PP Plastic Plywood Type

>>>

ROCPLEX PP Plastic Plywood Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | Tempered surface | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | / | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 E1 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 530-720 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX PP Plastic Plywood Features & Benefits

- Durability: The plastic coating significantly enhances the plywood’s strength, making it suitable for heavy-duty applications.

- Waterproof: Excellent moisture resistance ensures longevity, even in damp environments.

- Chemical Resistance: The plastic layer provides protection against chemicals, making it ideal for industrial use.

- Easy Maintenance: Smooth surface allows for easy cleaning and maintenance, essential for hygienic applications.

- Versatility: Suitable for a wide range of applications, including formwork, flooring, and walls.

- Sustainability: Manufactured with eco-friendly practices, reducing environmental impact.

- Ease of Use: Lightweight yet strong, facilitating easy handling and installation.

- Cost-Effective: Long lifespan and reusability make it a cost-effective choice for construction projects.

- Enhanced Performance: Combines the best properties of timber and plastic for superior performance.

>>>

ROCPLEX PP Plastic Plywood Certified By

|  |  |  |

Plastic Plywood is ideal for formwork in construction projects, providing a durable and reusable solution that stands up to multiple uses. Its waterproof properties are particularly beneficial in areas exposed to moisture, ensuring longevity and reliability.

Flooring applications benefit greatly from Plastic Plywood’s strength and resistance to wear and tear. It provides a stable and durable surface that can withstand heavy foot traffic and other stresses common in commercial and industrial settings.

For wall applications, Plastic Plywood offers a smooth and easy-to-clean surface, making it suitable for environments that require hygiene and ease of maintenance, such as food processing plants and healthcare facilities.

Choose ROCPLEX PP plastic faced plywood sheets for your next construction project and experience the benefits of a durable, waterproof, and versatile building material. Contact us today to learn more and place your order!

>>>

ROCPLEX CDX Pine Plywood FAQ

Q: What is PP Plastic Faced Plywood Panels?

A: PP Plastic Faced Plywood Panel is a type of plywood coated with a plastic layer to enhance its durability, waterproof properties, and resistance to chemicals. This combination makes it ideal for various construction applications, offering superior strength and longevity compared to traditional plywood.

Q: What are the benefits of using PP Plastic Coated Plywood sheet in construction?

A: PP plastic coated plywood sheet offers several benefits, including high durability, excellent moisture resistance, chemical resistance, and ease of maintenance. It is versatile and can be used for formwork, flooring, and wall applications. Its enhanced performance and long lifespan make it a cost-effective choice for demanding construction projects.

Q: Is PP Plastic Face Plywood environmentally friendly?

A: Yes, ROCPLEX PP Plastic Face Plywood is manufactured using eco-friendly practices that minimize environmental impact. The combination of sustainable timber and advanced plastic coating technology ensures that the product meets high environmental standards, making it a responsible choice for construction projects.

Q: Can PP Plastic Plywood be used outdoors?

A: Absolutely. The waterproof and durable nature of PP Plastic Plywood makes it ideal for outdoor applications. It can withstand harsh environmental conditions without compromising its structural integrity, making it suitable for use in outdoor formwork, flooring, and walls.

Q: How do you maintain PP Plastic Faced Plywood?

A: Maintaining PP Plastic Faced Plywood is straightforward due to its smooth, plastic-coated surface. It can be easily cleaned with standard cleaning agents, and its resistance to moisture and chemicals ensures that it remains in good condition with minimal effort. Regular inspections and cleaning will help extend its lifespan even further.