ROCPLEX Particle Board

ROCPLEX Particle Board

ROCPLEX Particle Board is a durable and economical engineered panel made from wood chips bonded with high-quality resin under heat and pressure. Designed for interior use, the board provides a flat, smooth surface ideal for veneering, laminating, or painting. Its even structure makes it easy to machine, drill, and edge-band without chipping or breaking.

ROCPLEX focuses on uniform density and reliable core strength. This consistency allows furniture manufacturers to maintain precision across multiple pieces and ensures structural integrity in end products. ROCPLEX Particle Board is an ideal choice for cabinetry, shelving, shopfitting, and interior partitions where surface stability and affordability are critical.

Common pain points for buyers include surface bubbling, inconsistent core density, and low screw-holding capacity. ROCPLEX solves these issues through strict quality control, ensuring balanced moisture content, optimal pressing, and strong internal bonding. The result is a panel that performs reliably in all standard interior applications.

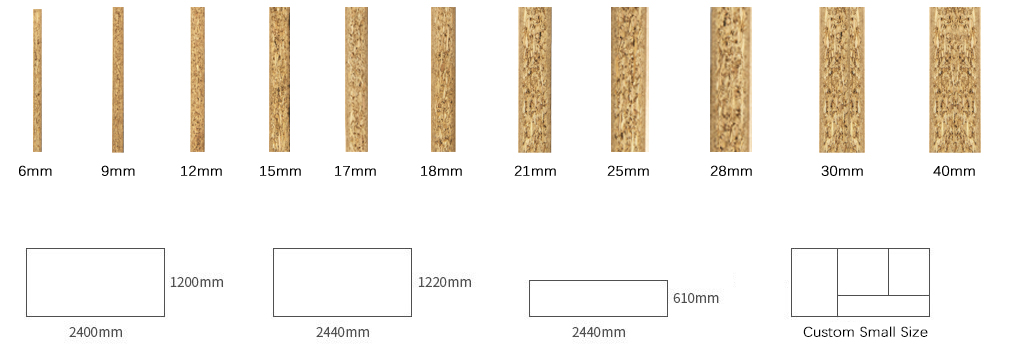

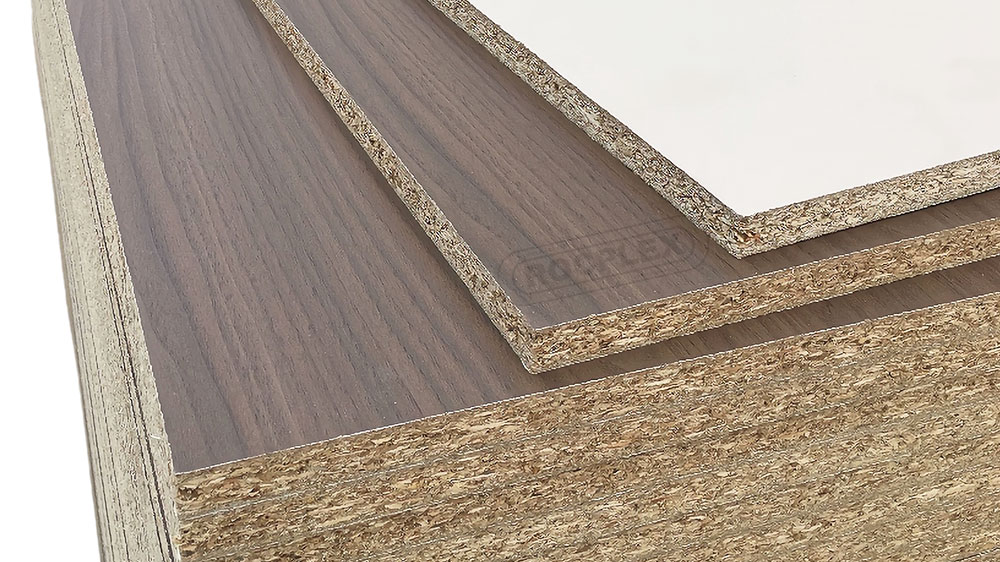

To meet varying market demands, ROCPLEX Particle Board comes in different sizes, thicknesses, and grades. Plain, laminated, or melamine-faced options are available to match diverse project requirements. Whether used for flat-pack furniture or commercial interiors, ROCPLEX delivers both quality and value.

>>>

ROCPLEX Particle Board Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 6 | 2440 | 1220 | Melamine | AA |

| 9 | 2440 | 1220 | Melamine | AA |

| 12 | 2440 | 1220 | Melamine | AA |

| 15 | 2440 | 1220 | Melamine | AA |

| 17 | 2440 | 1220 | Melamine | AA |

| 18 | 2440 | 1220 | Melamine | AA |

| 21 | 2440 | 1220 | Melamine | AA |

| 25 | 2440 | 1220 | Melamine | AA |

| 30 | 2440 | 1220 | Melamine | AA |

| 40 | 2440 | 1220 | Melamine | AA |

>>>

ROCPLEX Particle Board Patterns and Colors

>>>

ROCPLEX Particle Board Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | G2S | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | / | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 E1 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 650-720 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX particle board is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX Particle Board Features & Benefits

- Smooth and Uniform Surface

- ROCPLEX Particle Board features a fine, even surface that accepts laminates, veneers, and paints with minimal preparation.

- Consistent Density Core

- Engineered for uniform strength, the board resists warping and delivers stable performance during cutting and assembly.

- Excellent Machinability

- It cuts cleanly without chipping, holds screws firmly, and is easy to mill or shape for detailed joinery or panel work.

- Affordable and Efficient

- A cost-effective alternative to plywood or MDF, ROCPLEX Particle Board helps reduce material costs in large-scale production.

- Available in Multiple Grades

- From standard panels to moisture-resistant and laminated versions, ROCPLEX offers flexibility for different industry requirements.

- Eco-Friendly Production

- Manufactured using recycled wood fibers and low-emission adhesives, ROCPLEX supports sustainable practices and indoor air safety.

>>>

ROCPLEX Particle Board Certified By

|  |  |  |

ROCPLEX Particle Board is widely used in the production of flat-pack and custom furniture. It offers reliable performance for desks, cabinets, wardrobes, and shelving units where a smooth finish is essential.

In commercial construction, the board is perfect for internal wall linings, exhibition panels, and office partition systems. Its low cost and adaptability make it ideal for high-volume interior fit-outs.

The board also supports laminated applications such as kitchen panels, shop counters, and worktops. When surfaced with decorative films, ROCPLEX becomes a versatile component in modern furniture and retail design.

Looking for a reliable, affordable, and high-performance panel solution? ROCPLEX Particle Board is the ideal material for furniture makers, interior fit-out contractors, and global wholesalers. Contact ROCPLEX today to learn more about product availability, custom sizing, and wholesale options tailored to your project needs.

>>>

ROCPLEX Particle Board FAQ

Q: What is Particle Board?

A: Particle Board is an engineered wood panel made from wood particles bonded with resin under high heat and pressure.

Q: What are the main uses of ROCPLEX Particle Board?

A: Common applications include furniture, cabinetry, shelving, wall panels, and interior partition systems.

Q: Can ROCPLEX Particle Board be laminated or veneered?

A: Yes. It has a smooth surface ideal for applying decorative laminates, veneers, or melamine films.

Q: What thicknesses and sizes are available?

A: ROCPLEX Particle Board comes in a wide range of thicknesses (6mm–25mm) and standard/custom sizes. Contact ROCPLEX for specifications.

Q: How does ROCPLEX ensure consistent quality?

A: Each board is produced under strict quality control to ensure uniform density, balanced moisture content, and strong internal bonding.