Scaffold Boards – SENSOplank

Scaffold Boards – SENSOplank

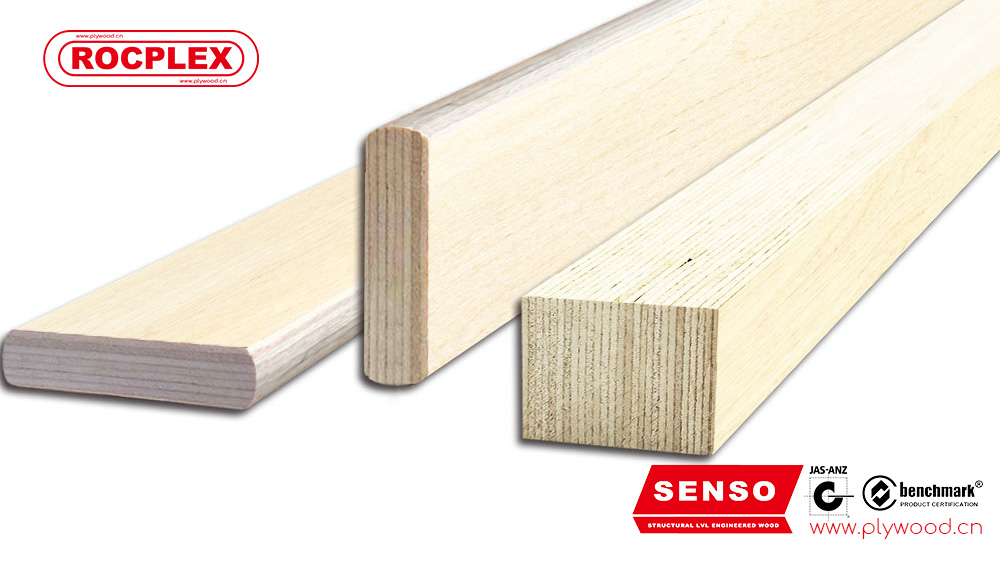

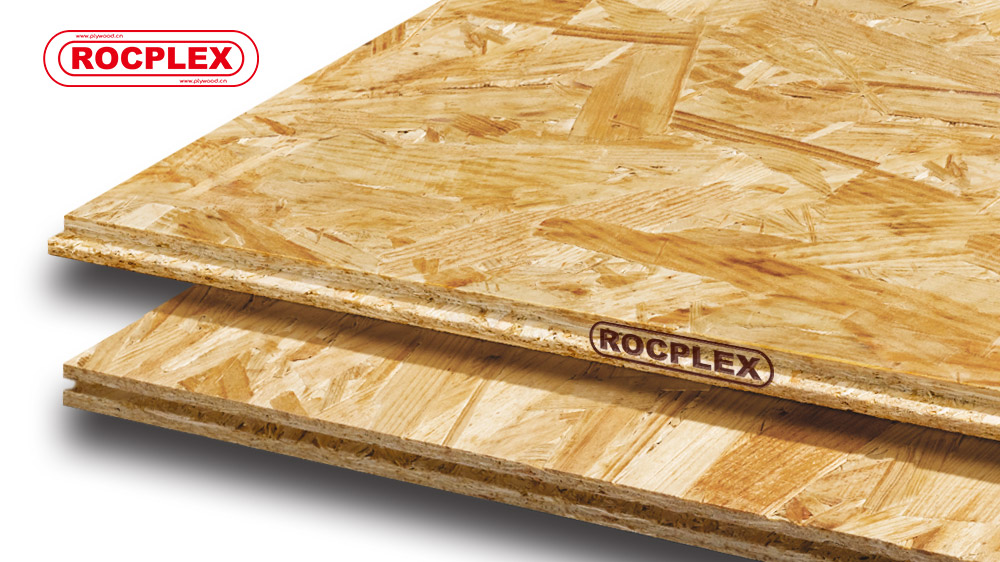

SENSOplank Scaffold Boards are crafted from premium timber, ensuring high strength and performance across a wide range of construction scenarios. Each board is kiln-dried, stress-tested, and inspected for structural consistency. This guarantees the durability required to withstand dynamic loads, harsh conditions, and long-term usage.

These boards are manufactured to meet strict international safety codes, including OSHA and BS standards. Every SENSOplank Scaffold Board undergoes a treatment process to improve resistance against moisture, fungal decay, and surface degradation. Their structural integrity helps protect workers on high-rise and mid-rise construction projects.

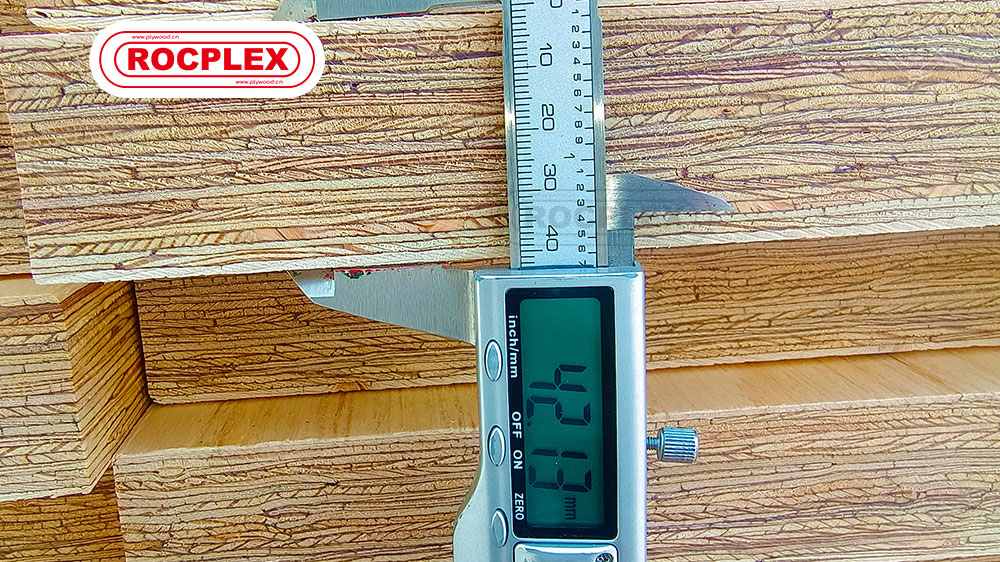

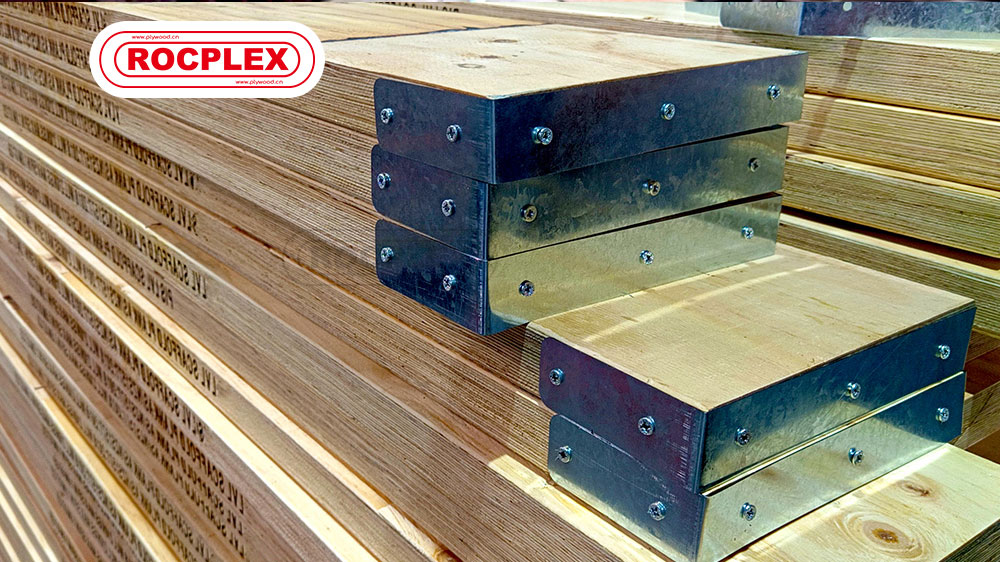

To maintain precise load-bearing consistency, SENSOplank Scaffold Boards are produced with strict dimensional tolerances. This enhances scaffold stability while reducing shifting or deflection during use. The anti-slip surface and sharp edge finish improve both safety and handling on the job site.

SENSO also offers custom lengths and sizes to match regional preferences and industry-specific needs. From standard dimensions to specialized cuts for system scaffold compatibility, SENSOplank ensures a tailored solution that integrates seamlessly into any access platform system.

SENSO commitment to environmentally responsible sourcing ensures each board is produced from legally harvested, sustainable wood. With certifications available upon request, buyers can confidently meet project sustainability goals without compromising performance.

>>>

Scaffold Boards – SENSOplank Standard Sizes

| Width (mm) | Thickness (mm) | Length (m) |

|

225 240 300 |

38 42 45 |

1.80 1.90 2.45 2.65 2.90 3.00 3.30 3.60 3.90 4.20 4.50 4.80 5.90 |

>>>

Scaffold Boards – SENSOplank Type

>>>

Scaffold Boards – SENSOplank Specifications

| Joints Face | Bond | ||||||||||||

| Scarf | Type A (Marine) (AS/NZS 2098 & AS 2754) | ||||||||||||

| Joints | Finish | ||||||||||||

| Scarf and / or butt jointed | Arrises removed – (approx. 3mm chamfer) painted | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | Phenolic Super E0 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 450-580 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of SENSO LVL is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

Scaffold Boards – SENSOplank Features & Benefits

- High Strength Timber Construction

- Designed for superior load performance in demanding scaffold setups.

- OSHA and International Compliance

- Meets or exceeds global scaffolding safety regulations and testing standards.

- Anti-Slip Surface Finish

- Reduces slipping risks, enhancing on-site worker safety in all weather conditions.

- Moisture and Decay Resistant

- Treated against fungal attack and water absorption, suitable for repeated use.

- Customizable Sizes and Grades

- Available in various thicknesses, lengths, and visual grades for regional markets.

- Eco-Friendly and Certified

- Produced from legal, sustainable wood with third-party certification options available.

>>>

Scaffold Boards – SENSOplank Certified By

|  |  |  |  |  |  |

SENSOplank Scaffold Boards are widely used across building construction, infrastructure development, industrial maintenance, and petrochemical projects. Their versatility suits both fixed and modular scaffold systems.

Construction companies rely on SENSOplank for formwork staging, access platforms, and temporary flooring during roofing, façade installation, or renovation works. The strength and anti-slip features make them ideal for high-traffic and elevated zones.

These boards are also suitable for commercial and residential projects, especially where OSHA-compliant scaffolding is mandatory. Their adaptability and safety ratings make them a trusted choice for contractors and scaffold rental firms.

Upgrade your site safety and efficiency with SENSOplank Scaffold Boards. Contact ROCPLEX today to request specifications, pricing, and delivery terms tailored to your scaffold requirements.

>>>

Scaffold Boards – SENSOplank FAQ

Q: What are SENSOplank Scaffold Boards?

A: SENSOplank Scaffold Boards are high-performance timber boards designed for use in scaffolding systems. They provide superior strength, durability, and compliance with international safety standards.

Q: Are SENSOplank Scaffold Boards OSHA compliant?

A: Yes. SENSOplank Scaffold Boards meet OSHA safety standards and are also manufactured to comply with international certifications such as BS2482.

Q: What materials are used in SENSOplank Scaffold Boards?

A: These boards are made from kiln-dried, high-strength timber. The wood is treated for moisture and decay resistance to ensure long-term performance.

Q: Are the boards resistant to water and weather exposure?

A: Yes. SENSOplank Scaffold Boards are treated to resist water absorption, surface wear, and fungal attack, making them suitable for outdoor use.

Q: What makes SENSOplank different from other wooden scaffold boards?

A: SENSOplank offers superior strength grading, consistent sizing, anti-slip finishing, and customizable solutions tailored for global markets.