Xlife Plastic Antislip Plywood

ROCPLEX Xlife Plastic Antislip Plywood

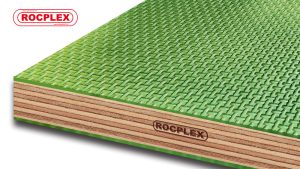

ROCPLEX Xlife plastic antislip plywood is the result of 30 months of engineering refinement. Every panel undergoes a precise 26-step production process. This ensures stable performance under varied climate conditions and heavy-duty use. The plastic-coated surface is hot-pressed with a 10-times deeper texture than standard film-faced plywood. This delivers maximum surface grip, reducing accidents in slippery environments.

The panel structure consists of full hardwood or high-grade birch core veneers. These are bonded using waterproof phenolic resin, ensuring dimensional stability. Edges are coated with a durable water-repellent sealant, blocking moisture intrusion and extending panel lifespan in outdoor and damp areas.

Unlike regular antislip boards, ROCPLEX Xlife retains its texture over prolonged use. It resists surface flattening from foot traffic or equipment loads. The outer plastic layer shields the board from acid, grease, oils, and solvents often encountered in transport and industrial zones.

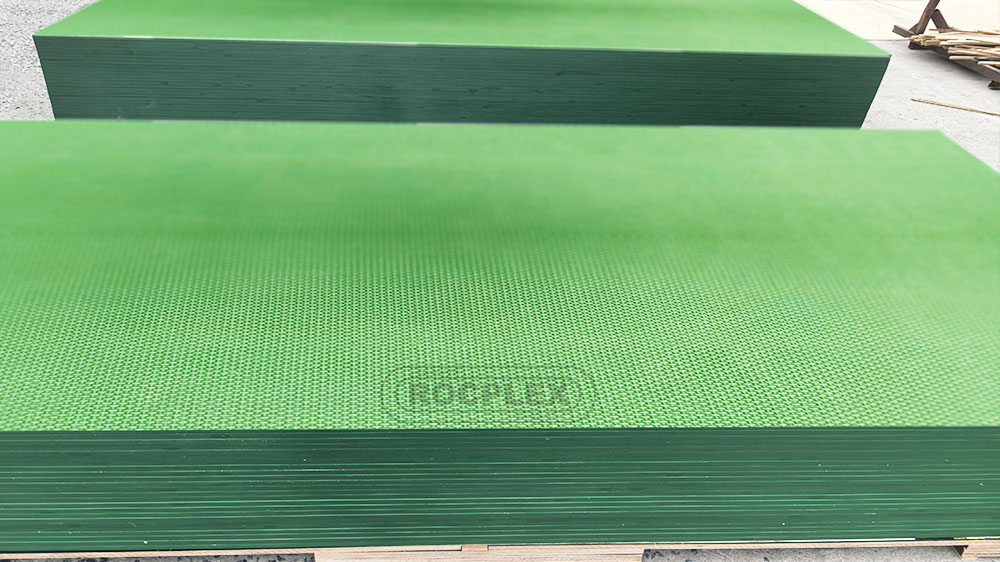

Each Xlife plastic antislip plywood panel is tested for strength, load capacity, and skid resistance. ROCPLEX offers various colors and branding options to suit customer specifications. Whether it’s used on a truck bed or scaffold platform, this board is built to perform safely and reliably.

>>>

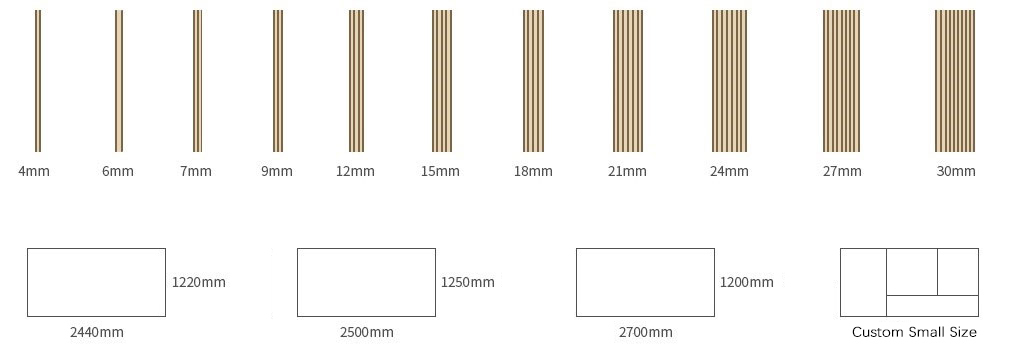

ROCPLEX Xlife Plastic Antislip Plywood Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Hardwood / Birch | AA |

| 7 | 2440 | 1220 | Hardwood / Birch | AA |

| 9 | 2440 | 1220 | Hardwood / Birch | AA |

| 12 | 2440 | 1220 | Hardwood / Birch | AA |

| 15 | 2440 | 1220 | Hardwood / Birch | AA |

| 17 | 2440 | 1220 | Hardwood / Birch | AA |

| 18 | 2440 | 1220 | Hardwood / Birch | AA |

| 19 | 2440 | 1220 | Hardwood / Birch | AA |

| 25 | 2440 | 1220 | Hardwood / Birch | AA |

| 28 | 2440 | 1220 | Hardwood / Birch | AA |

>>>

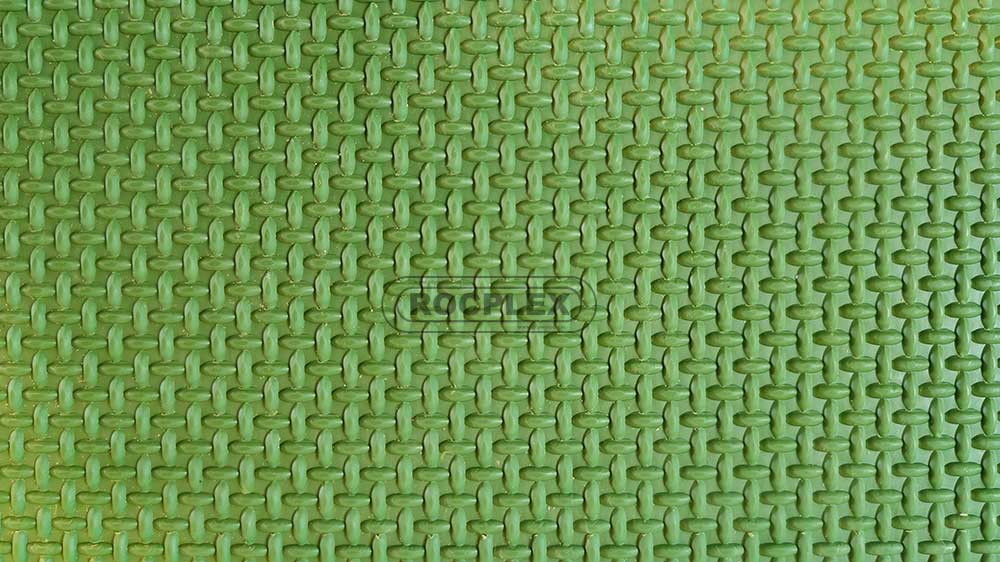

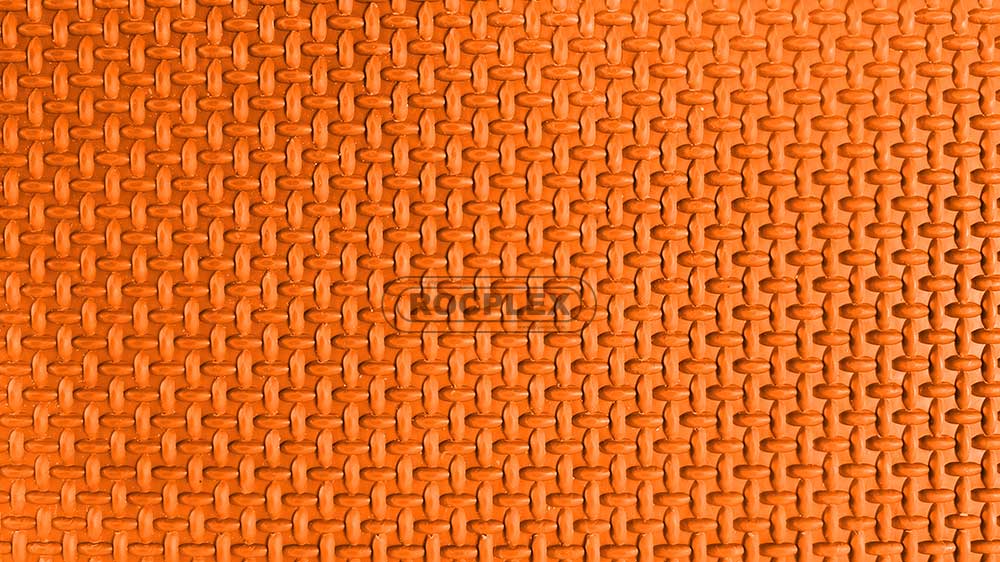

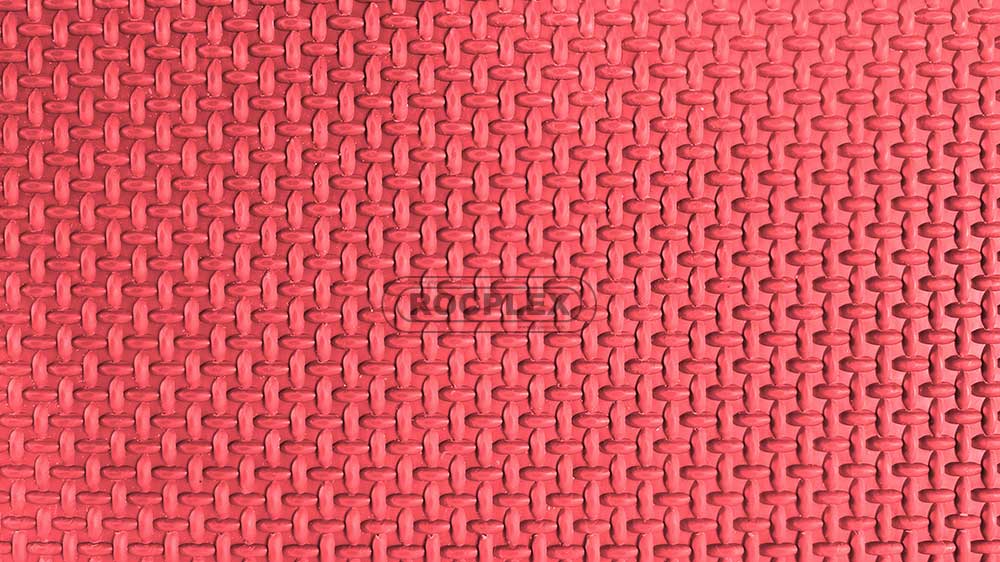

ROCPLEX Xlife Plastic Antislip Plywood Regular Optional Colors

>>>

ROCPLEX Xlife Plastic Antislip Plywood Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | Antislip | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | A Bond | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 630-720 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

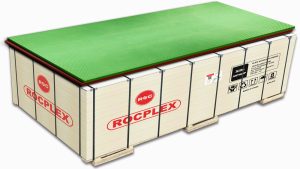

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX Xlife Plastic Antislip Plywood Features & Benefits

- Deep Pattern Antislip Surface

- Embossed plastic coating is 10x deeper than standard antislip plywood. Excellent grip in wet and dry use.

- Waterproof and Weather-Resistant Build

- Sealed edges and phenolic resin ensure long-term moisture protection in coastal or rainy environments.

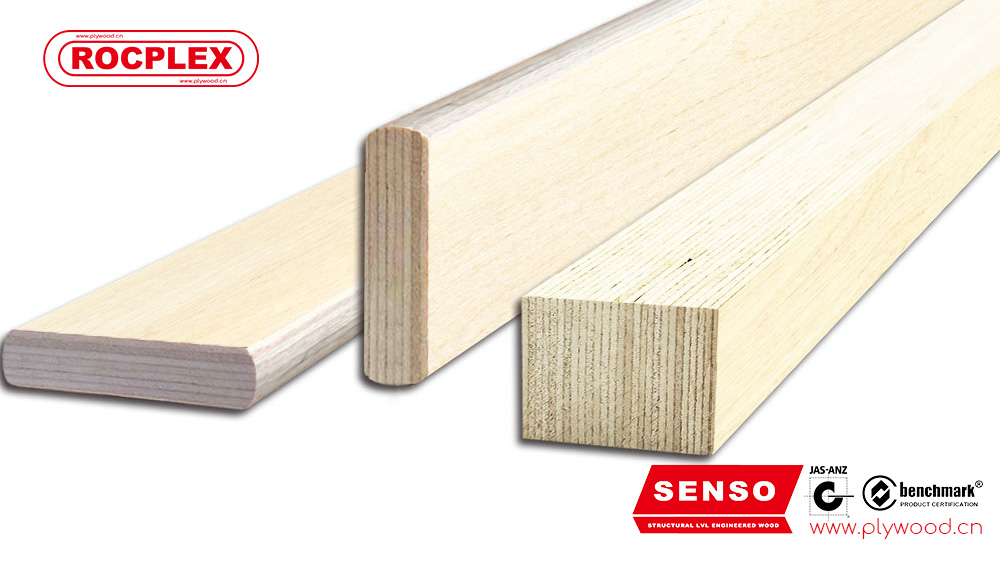

- Engineered Core Strength

- Composed of calibrated birch or hardwood veneers, laminated for maximum strength and minimal deformation.

- Chemical and Abrasion Resistant

- Plastic overlay defends against harsh chemicals, frequent impacts, and surface erosion over time.

- Customizable Specifications

- Available in various sizes, colors, and logos. ROCPLEX can tailor panel thickness and sealing to project needs.

- Zero Skid Performance Decline

- Surface texture maintains integrity even under prolonged wear, ensuring continued safety without peeling or cracking.

>>>

ROCPLEX Xlife Plastic Antislip Plywood Certified By

|  |  |  |

ROCPLEX Xlife plastic antislip plywood performs on job sites, trailers, and equipment platforms. It supports stable footing on scaffold planks during high-rise construction tasks. The deep-pattern surface reduces slip risk for workers.

On mobile stages or event decks, the panel enables safe movement even under dynamic crowd traffic. It ensures firm grip for both performers and equipment.

For trailers and truck floors, the board delivers strong friction under oily and wet cargo conditions. It helps secure machinery during transport.

Also ideal for ramps, loading bays, and lifting platforms, the board handles heavy movement without surface fatigue.

ROCPLEX Xlife plastic antislip plywood delivers unmatched traction, durability, and stability for transport and scaffold applications. If you’re seeking reliable skid-resistant plywood built for tough environments, ROCPLEX is your trusted supplier. Contact ROCPLEX today to get a quote or request a custom order for your next heavy-duty project.

>>>

ROCPLEX Xlife Plastic Antislip Plywood FAQ

Q: What is ROCPLEX Xlife Plastic Antislip Plywood?

A: ROCPLEX Xlife Plastic Antislip Plywood is a high-performance, plastic-coated plywood panel designed for maximum grip and durability. It features a deeply embossed surface, bonded to a hardwood or birch core with waterproof phenolic glue.

Q: What makes Xlife different from standard antislip plywood?

A: The Xlife panel has a textured plastic surface that is 10 times deeper than regular film-faced antislip plywood. It provides superior traction and long-term resistance to wear, water, and chemicals.

Q: Where is Xlife Plastic Antislip Plywood used?

A: Common applications include truck and trailer floors, scaffold planks, loading ramps, stage platforms, and industrial walkways. It’s ideal for high-traffic and wet environments.

Q: What sizes and thicknesses are available?

A: ROCPLEX supplies Xlife panels in multiple thicknesses (typically 12mm–21mm) and standard sizes like 1220×2440mm. The maximum size can be 6000mm*2000mmCustom sizes are available upon request.

Q: Can I order custom colors or branding?

A: Yes. ROCPLEX offers customization options such as colored plastic surfaces, edge sealing, and logo printing to suit your project or branding needs.