BS1088 Certified Marine Plywood

ROCPLEX BS1088 Certified Marine Plywood

ROCPLEX BS1088 Certified Marine Plywood is built using selected hardwood veneers and WBP (Weather and Boil Proof) glue, fully complying with BS1088:2003 requirements. It undergoes precise construction and quality control to ensure uniform bonding, consistent thickness, and minimal internal defects.

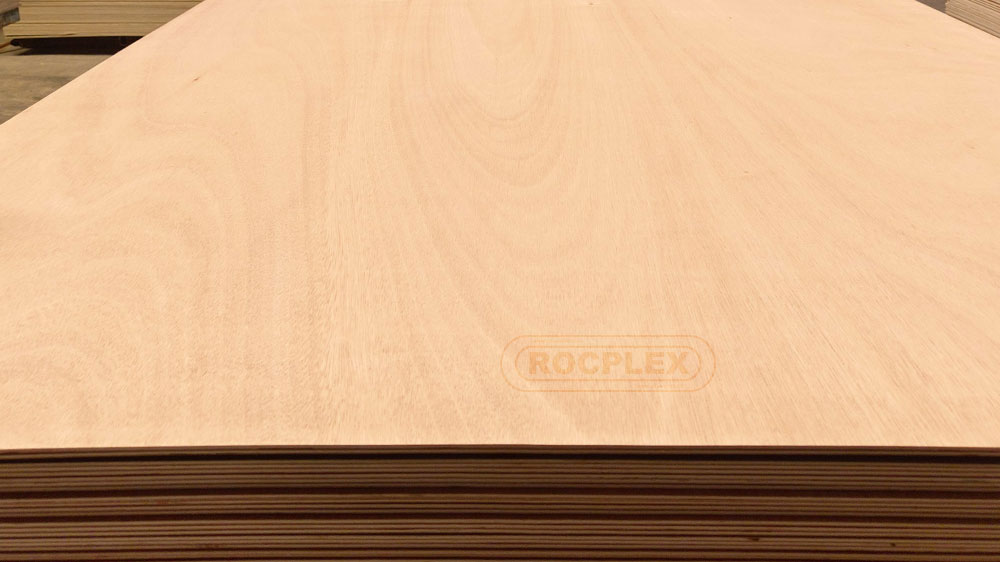

The panel is constructed with multiple core layers and outer faces, arranged in cross-laminated fashion. This enhances dimensional stability and structural integrity under changing moisture and temperature conditions.

The adhesive used is phenolic-based resin, providing strong resistance to water immersion, humidity, and temperature fluctuation. Each sheet undergoes mechanical testing and visual inspection for core gaps, bonding quality, and surface finish.

The plywood offers a smooth sanded face, suitable for further coating or sealing. It resists rot and fungal growth in wet or submerged environments when properly treated. ROCPLEX offers sizes from 4mm to 25mm thickness and custom dimensions upon request.

This product meets international marine, construction, and export-grade plywood expectations. ROCPLEX ensures tight quality control and consistent standards for every batch.

>>>

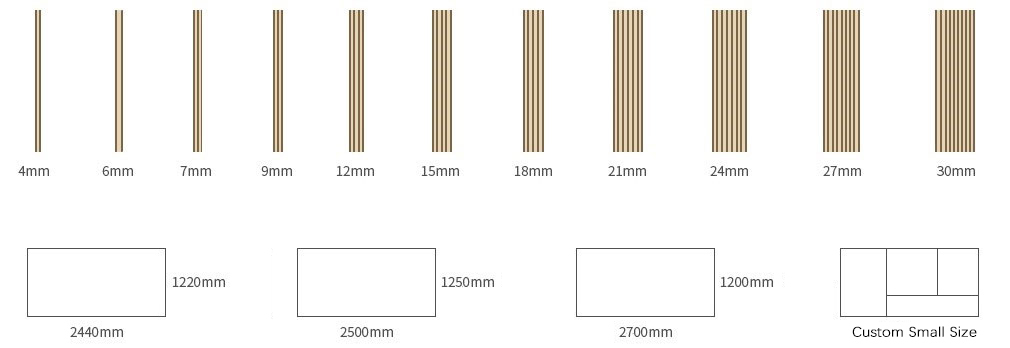

ROCPLEX BS1088 Certified Marine Plywood Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 7 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 9 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 12 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 15 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 17 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 18 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 19 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 25 | 2440 | 1220 | Okoume | BS1088 – Marine |

| 28 | 2440 | 1220 | Okoume | BS1088 – Marine |

>>>

ROCPLEX BS1088 Certified Marine Plywood

>>>

ROCPLEX BS1088 Certified Marine Plywood Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | G2S | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | A Bond | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 480-530 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLEX BS1088 Certified Marine Plywood Features & Benefits

- Complies with BS1088 Marine Standard

- Manufactured under strict technical requirements for use in high-moisture or submerged applications.

- 100% Okoume Core Construction

- Built from selected hardwood veneers to provide strength and resistance to delamination.

- WBP Phenolic Adhesive System

- Ensures reliable bonding that withstands boiling water, steam, and tropical conditions.

- Void-Free and Consistent Core

- Minimizes gaps and core imperfections that reduce performance in wet applications.

- Rot and Fungal Resistance

- Enhanced durability against microbial degradation in marine or tropical environments.

- Smooth Surface Finish

- Sanded face suitable for direct painting, sealing, or additional overlay applications.

>>>

ROCPLEX BS1088 Certified Marine Plywood Certified By

|  |  |  |

ROCPLEX BS1088 Marine Plywood is widely used in boat construction, including hulls, decks, and bulkheads where water exposure is frequent.

It is suitable for wet-area furniture, including kitchen cabinets, bathroom vanities, and locker systems requiring high moisture resistance.

The plywood is applied in outdoor structures like docks, piers, and shelters that demand waterproof performance and structural reliability.

It can also be used in transport vehicle flooring, packaging for moisture-sensitive goods, and wall paneling in coastal environments.

Need reliable plywood for marine or exterior construction? Contact ROCPLEX now to source BS1088 Certified Marine Plywood trusted in demanding environments worldwide.

>>>

ROCPLEX BS1088 Certified Marine Plywood FAQ

Q: What does BS1088 Marine Plywood mean?

A: BS1088 Marine Plywood refers to plywood manufactured according to British Standard 1088, ensuring superior durability, bonding strength, and moisture resistance.

Q: What wood species is used in ROCPLEX BS1088 plywood?

A: ROCPLEX uses selected light and hard okoume veneers with uniform grain and high density to meet the structural and performance standards of BS1088.

Q: What kind of glue is used for marine plywood?

A: ROCPLEX applies WBP phenolic adhesive. This glue type resists boiling water, making the panels suitable for extreme moisture exposure.

Q: What makes BS1088 plywood different from regular exterior plywood?

A: BS1088 plywood has stricter specifications regarding veneer quality, adhesive strength, and core uniformity, making it more reliable in wet environments.

Q: Is ROCPLEX BS1088 plywood resistant to rot and fungi?

A: Yes. The high-quality hardwood core and waterproof glue offer natural resistance to fungal decay and rot in wet or humid areas.