ROCPLY Structural Plywood

ROCPLY Structural Plywood

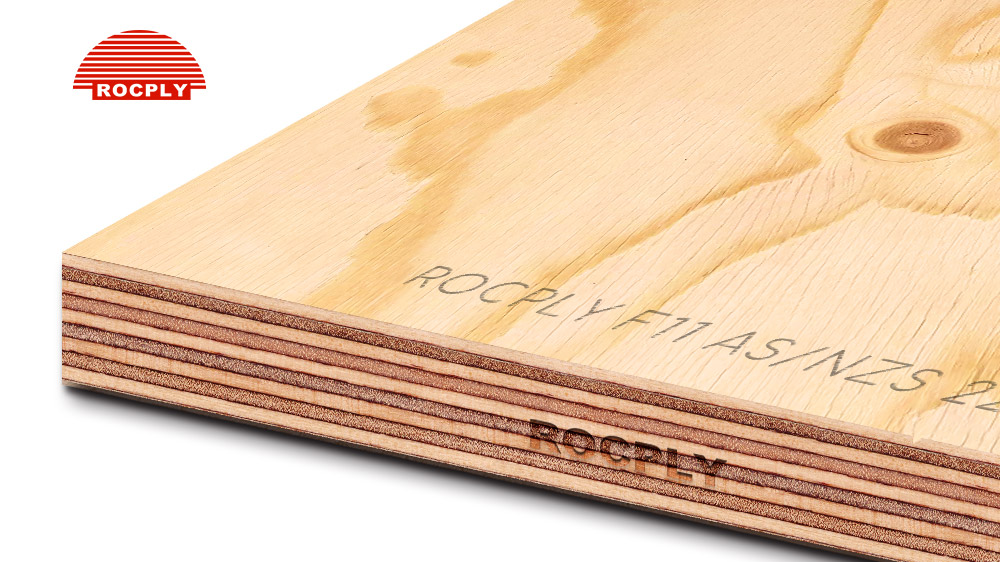

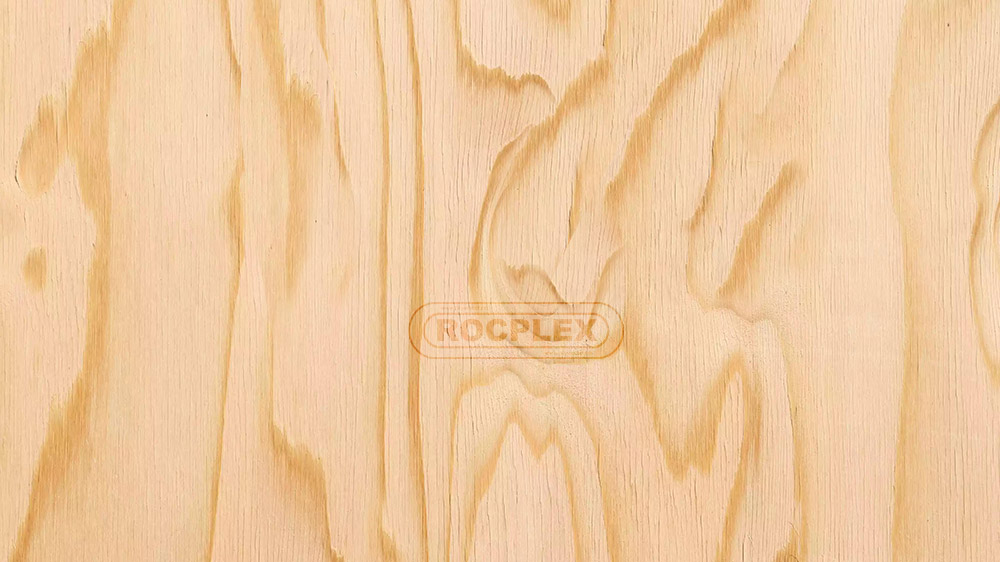

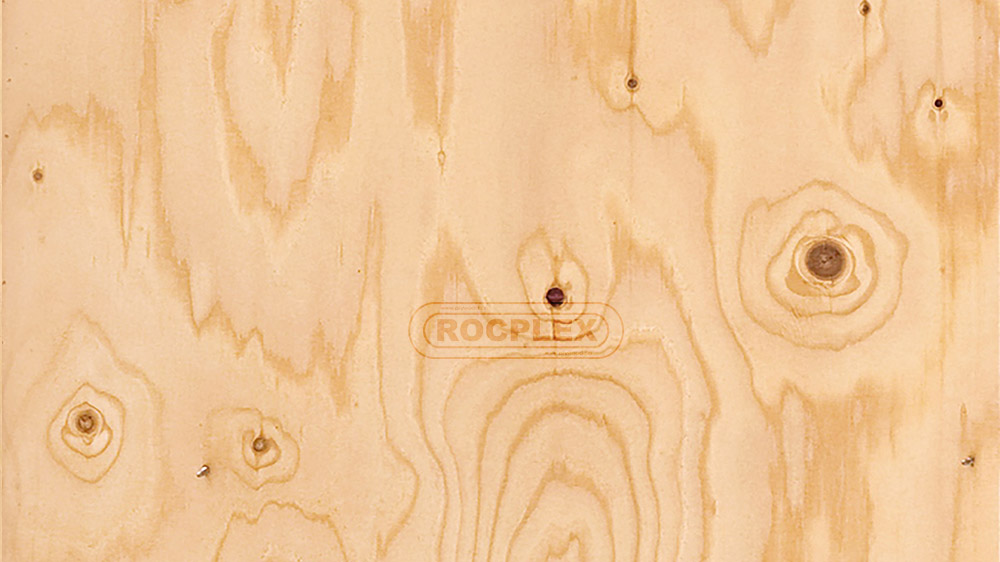

ROCPLY Structural Plywood is engineered with multiple layers of Pine or hardwood veneers, aligned at right angles to maximize strength and stability. Each panel is pressed with a water-resistant adhesive to ensure strong bonding and resistance to moisture.

The cross-laminated structure allows for excellent load distribution, minimizing bending and deflection under weight. This provides secure support in critical structural areas such as subfloors, joists, beams, and wall sheathing.

The face and core veneers are carefully selected to maintain uniform thickness and density across the sheet. This ensures optimal performance in cutting, fastening, and handling on construction sites.

Each board is subjected to rigorous testing for shear strength, moisture content, and dimensional accuracy. ROCPLY maintains production to meet local and international structural plywood standards for construction-grade use.

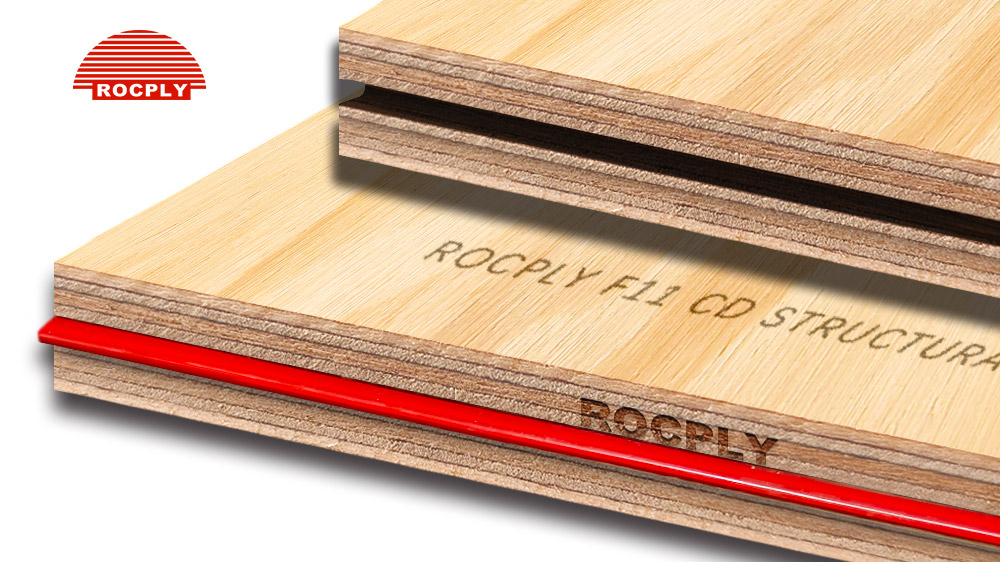

ROCPLY Structural Plywood is offered in untreated or treated options (H2S), providing flexibility for both internal and external applications. With its consistent strength, moisture resistance, and ease of installation, it ensures solid performance in demanding environments. ROCPLY Square Edge Structural Plywood meets Japan Agricultural Standards – Australia New Zealand AS/NZS 2269, making it a trusted solution for both residential and commercial projects. Ideal for builders who require a dependable, versatile material that stands.

>>>

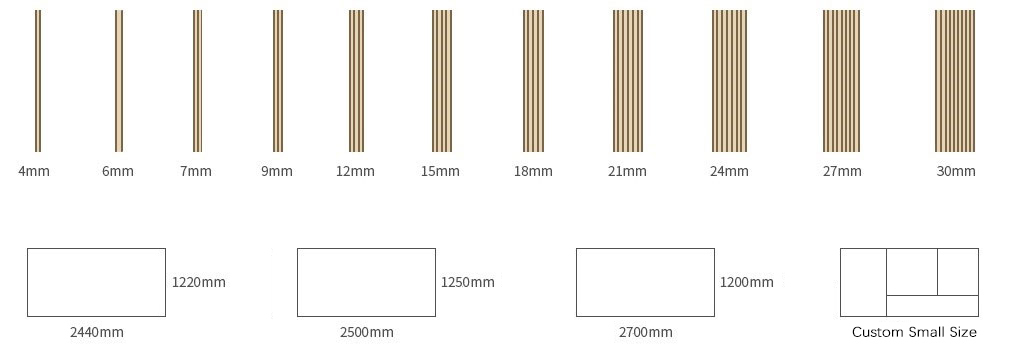

ROCPLY Structural Plywood Standard Sizes

| Thickness (mm) | Length(mm) | Width (mm) | Type | Grade |

| 4 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 7 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 9 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 12 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 15 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 17 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 18 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 19 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 25 | 2400 | 1200 | Pine / Hardwood | B/C/D |

| 28 | 2400 | 1200 | Pine / Hardwood | B/C/D |

>>>

ROCPLY Structural Plywood Type

>>>

ROCPLY Structural Plywood Grade

>>>

ROCPLY Structural Plywood Specifications

| Veneer Thickness | Finish | ||||||||||||

| Constant through the product thickness | G2S | ||||||||||||

| Joints | Bond | ||||||||||||

| Full sheet / Scarf and / or butt jointed | A Bond | ||||||||||||

| Moisture Content | Adhesive | ||||||||||||

| 8% – 15% (at time of despatch) | E0 |

||||||||||||

| Dimensional Tolerances | Density | ||||||||||||

| Available on request | 480-530 kg/m³ (approximately) | ||||||||||||

| Straightness | Certified | ||||||||||||

| Available on request | FSC / PEFC / CE / CARB | ||||||||||||

| Storage | Branding | ||||||||||||

| Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | Each pallet of ROCPLEX plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards |

>>>

ROCPLY Structural Plywood Features & Benefits

- ROC Plywood has been trusted globally for over 25 years.

- Experts in structural plywood design and manufacturing processes.

- Available untreated and H2S treated

- Easy to work with using traditional building tools.

- Clearly branded for easy identifcation on-site.

- Engineered to exact tolerances.

- Low formaldehyde emission (E0)

- Available PEFC or FSC “Chain of Custody” certifed on request.

- CERTMARK Certified

- BENCHMARK Certified

- OEM or ODM service available.

>>>

ROCPLY Structural Plywood Certified By

|  |  |  |  |  |  |

ROCPLY Structural Plywood is commonly used in house framing and floor decking. It performs well under flooring materials like hardwood, tile, and laminate.

Contractors choose it for roof sheathing where wind uplift, weight, and weather exposure are concerns. Its rigidity helps maintain the roof system’s structural shape.

It is also applied in wall cladding behind drywall or insulation systems. It provides added stability and nailing surface for internal or external walls.

This plywood is reliable in formwork systems, especially where reuse and rigidity are required during concrete pouring or shoring.

Need high-strength panels for your next building project? Contact ROCPLEX today for reliable Structural Plywood that meets the highest construction standards.

>>>

ROCPLY Structural Plywood FAQ

Q: What is Structural Plywood?

A: Structural Plywood is a multi-layered wood panel engineered for load-bearing construction applications, including floors, walls, and roofs.

Q: What makes ROCPLY Structural Plywood suitable for construction?

A: ROCPLY uses cross-laminated hardwood veneers and waterproof adhesive to ensure strength, stability, and resistance to moisture.

Q: Can this plywood be used outdoors?

A: Yes. The waterproof bonding and durable core make it suitable for external use, especially when protected with sealants or cladding.

Q: What sizes and thicknesses are available?

A: ROCPLY Structural Plywood is commonly produced in 1200/1220×2400/2440mm sheets with thicknesses from 4mm to 25mm. Custom dimensions are also available.

Q: Is ROCPLY Structural Plywood compliant with building codes?

A: Yes. It meets structural performance requirements for various markets and complies with national and international construction standards.