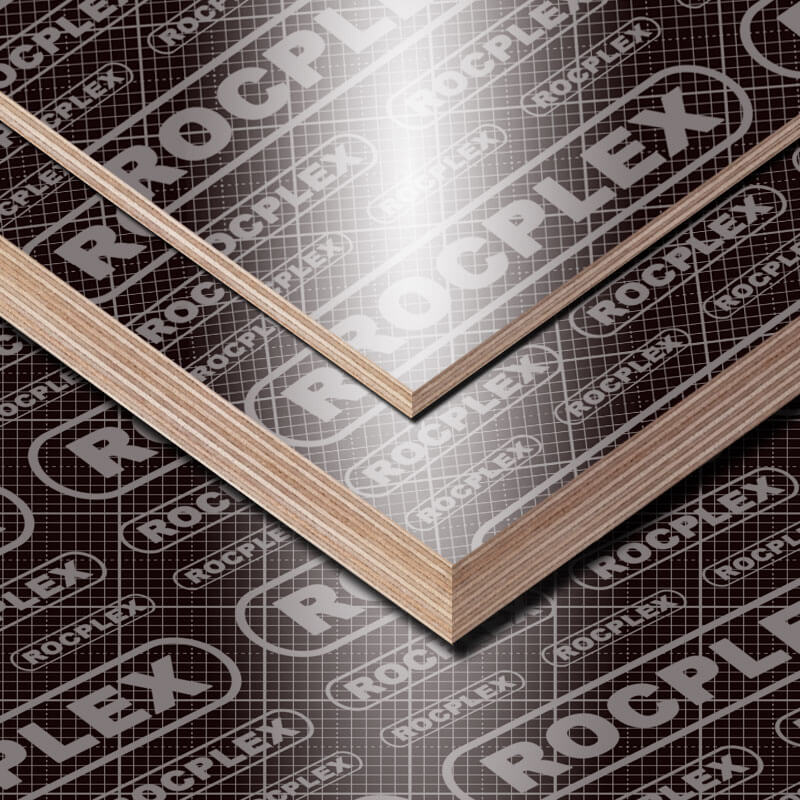

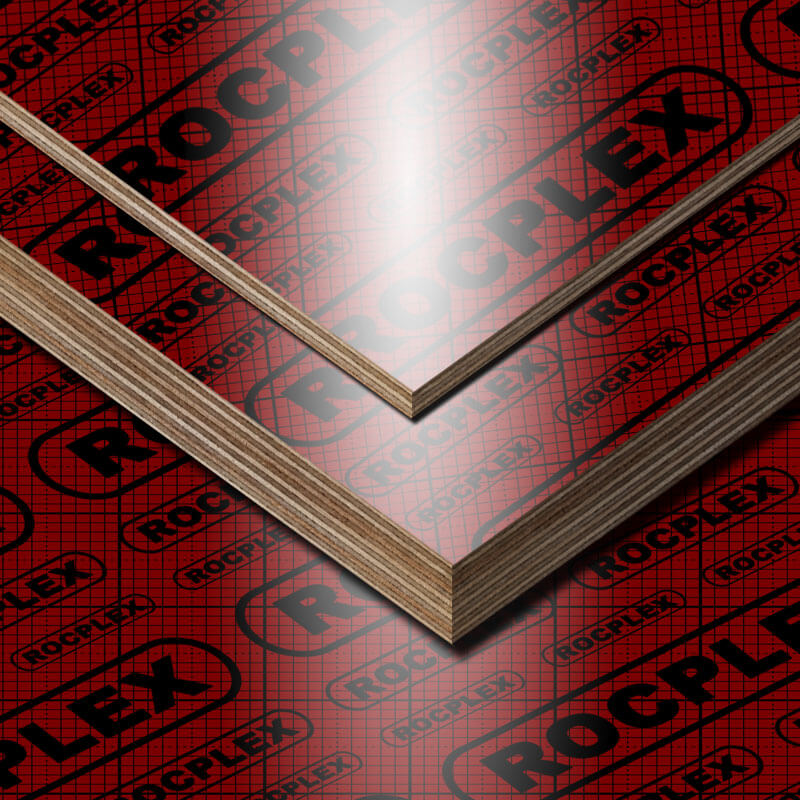

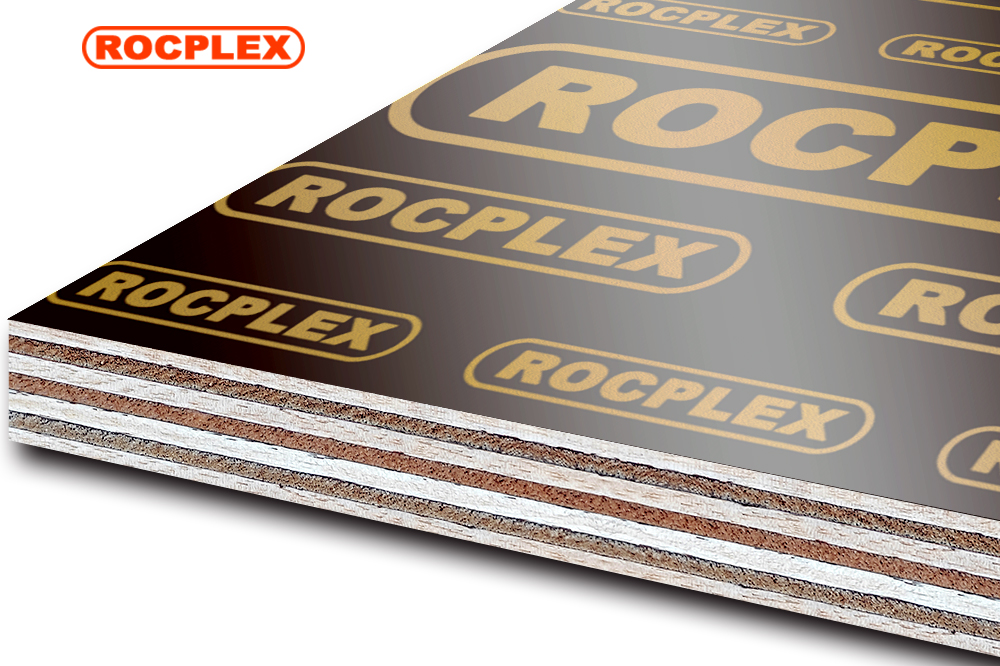

Elevate Your Builds with ROCPLEX Film Faced Plywood

ROCPLEX Film Faced Plywood stands out as a game-changing breakthrough in the dynamic world of building materials, combining durability, aesthetics, and adaptability. With an increasing need for dependable and aesthetically attractive construction materials, this specialty plywood variation has carved out a position for itself.

|

Mr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

IN 322 |

7.5 |

Check out |

|

|

2 |

Density |

kg/m3 |

IN 323 |

690 |

Check out |

|

|

3 |

Bonding Quality |

Bonding Quality |

Mpa |

IN 314 |

Max: 1.68 Min: 0.81 |

Check out |

|

Damage Rate |

% |

85% |

Check out |

|||

|

4 |

Bending Modulus of Elasticity |

Longitudinal |

Mpa |

IN 310 |

6997 |

Check out |

|

Lateral |

6090 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

59 |

Check out |

|

|

Lateral |

43.77 |

Check out |

||||

|

6 |

Cycle Life |

About 15-25 Repeated Using Times According To Projects By Formwork Application |

||||

|

Mr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

IN 322 |

8 |

Check out |

|

|

2 |

Density |

kg/m3 |

IN 323 |

605 |

Check out |

|

|

3 |

Bonding Quality |

Bonding Quality |

Mpa |

IN 314 |

Max: 1.59 Min: 0.79 |

Check out |

|

Damage Rate |

% |

82% |

Check out |

|||

|

4 |

Bending Modulus of Elasticity |

Longitudinal |

Mpa |

IN 310 |

6030 |

Check out |

|

Lateral |

5450 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

57.33 |

Check out |

|

|

Lateral |

44.79 |

Check out |

||||

|

6 |

Cycle Life |

About 12-20 Repeated Using Times According To Projects By Formwork Application |

||||

|

Mr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

IN 322 |

8.4 |

Check out |

|

|

2 |

Density |

kg/m3 |

IN 323 |

550 |

Check out |

|

|

3 |

Bonding Quality |

Bonding Quality |

Mpa |

IN 314 |

Max: 1.40 Min: 0.70 |

Check out |

|

Damage Rate |

% |

74% |

Check out |

|||

|

4 |

Bending Modulus of Elasticity |

Longitudinal |

Mpa |

IN 310 |

5215 |

Check out |

|

Lateral |

4796 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

53.55 |

Check out |

|

|

Lateral |

43.68 |

Check out |

||||

|

6 |

Cycle Life |

About 9-15 Repeated Using Times According To Projects By Formwork Application |

||||

|

ROCPLEX Film plywood Save cost |

||

|

|

Be special for phenolic glue and film |

The film-faced plywood can be disassembled and used repeatedly for both faces, saving 25% of the cost. |

|

|

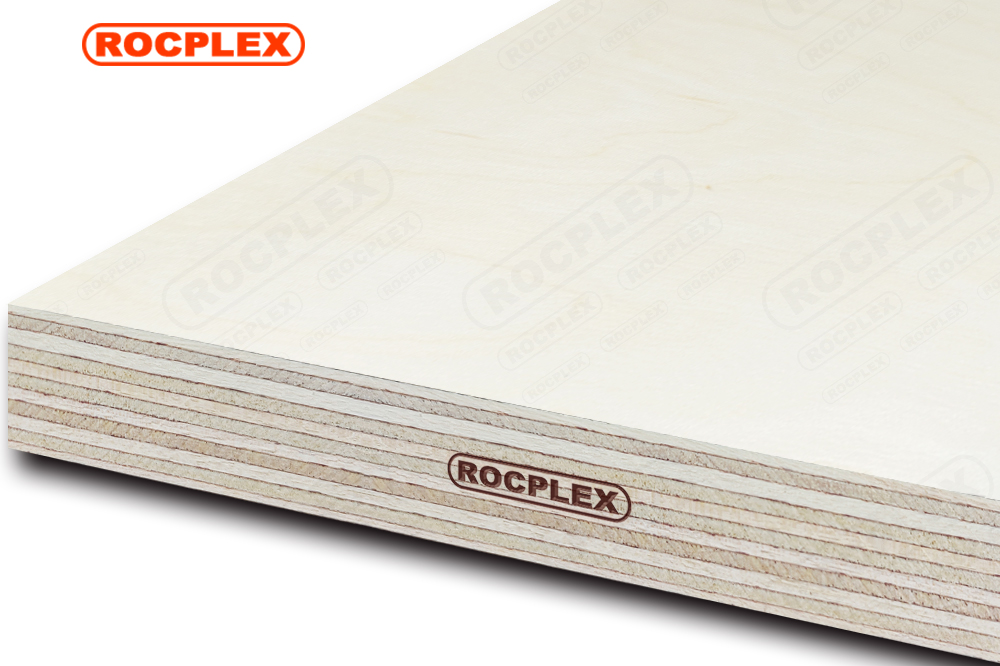

Optimization for the special grade of core |

|

|

|

Be special for adhesive |

|

|

ROCPLEX Film plywood Shorten the duration |

||

|

|

Excellent effect of de-molding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

|

|

|

Be easy to incise and blend |

|

|

ROCPLEX Film faced plywood the high-quality casting |

||

|

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

|

|

|

The edges are polished carefully |

|

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding Chinese film-faced plywood.