Premium Quality LVL Beams 240 x 45mm: Usage and Structural Performance

Delve into the world of structural excellence with 240 x 45mm premium LVL beams. This introduction examines their diverse applications and exceptional performance, showcasing how these beams are engineered to redefine strength and reliability in various construction projects. From residential constructions to commercial ventures, discover how these high-quality LVL beams empower architects and engineers, offering a versatile solution that harmonizes structural integrity with innovation.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

Understanding LVL Beams 240 x 45mm:

LVL beams measuring 240 x 45mm are engineered to provide substantial load-bearing capabilities. They are created through a process of bonding veneer layers, resulting in beams that combine strength with dimensional stability.

Applications and Working:

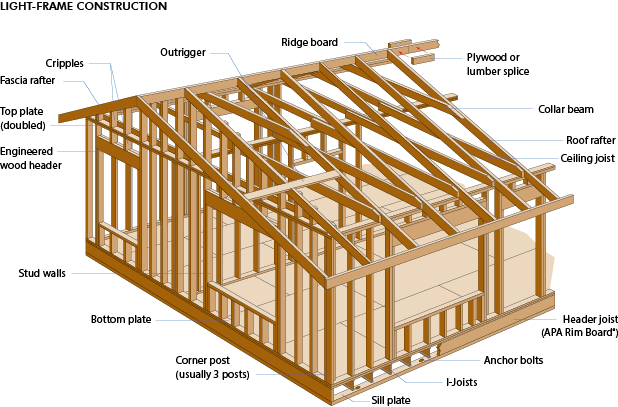

- Load-Bearing Structural Elements: LVL beams excel in creating load-bearing interior walls, partitions, and beams. Their strength allows them to support substantial loads, ensuring stability and structural integrity.

- Floor and Roof Systems: These beams are widely used in constructing floor and roof frameworks. Their reliable load-bearing capacity minimizes deflection and ensures durability in these critical building elements.

Advantages and Performance:

- Enhanced Load-Bearing: LVL beams 240 x 45mm are designed to bear significant loads, making them suitable for various load-bearing applications within a structure.

- Design Flexibility: Their consistent strength and stability empower architects and builders to explore innovative designs, extended spans, and open layouts.

LVL beams sized at 240 x 45mm play a vital role in modern construction due to their versatility and structural reliability. Whether reinforcing load-bearing elements, constructing stable floors and roofs, or supporting door and window openings, these beams exemplify the harmonious blend of engineering excellence and sustainable construction principles.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are specially professional in supplying LVL and plywood board.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

LVL Beams 240 x 45mm FAQ

Q: What is the maximum span of a 240 x 45mm LVL beam?

A: The maximum span of an LVL beam will depend on several factors, including the load it will be supporting and the specific product used. It is best to consult the manufacturer’s guidelines or a structural engineer to determine the appropriate span for your specific application.

Q: How are LVL beams installed?

A: LVL beams can be installed using traditional framing techniques, such as attaching them to posts or columns with bolts or screws. It is important to follow the manufacturer’s installation guidelines to ensure proper support and stability.

Q: Are LVL beams more expensive than traditional solid wood beams?

A: LVL beams can be more expensive than traditional solid wood beams, but they offer several advantages, including their strength and stability, uniformity, and environmental benefits. The cost difference will depend on the specific application and local market conditions.

Q: Are LVL beams fire-resistant?

A: LVL beams are made from wood, which is a combustible material. However, they are treated with fire retardants to improve their fire resistance. It is important to follow local building codes and regulations regarding fire safety.

Q: Can LVL beams be cut or drilled?

A: LVL beams can be cut and drilled using standard woodworking tools. However, it is important to follow the manufacturer’s guidelines to ensure proper structural integrity and avoid compromising the beam’s strength or stability.