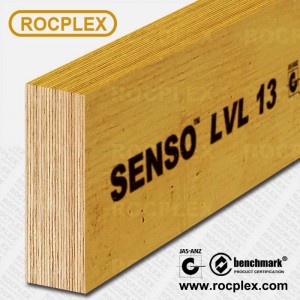

Top-Notch Eco-Friendly LVL Beams 150 x 45mm

Introducing the H2S Treated SENSO Framing LVL 13 – Structural LVL E13 Engineered Wood Beams, 150 x 45mm. This epitome of innovation and sustainability offers enduring strength, reshaping construction standards with its adaptability and performance.

Cutting-Edge Manufacturing Techniques for SENSO Framing LVL Beams

SENSO Framing LVL (Laminated Veneer Lumber) Beams, renowned for their exceptional quality and performance, are crafted using advanced manufacturing techniques that ensure their superiority in modern construction. Here are the key manufacturing techniques employed:

- Veneer Selection: The process begins with the careful selection of high-quality wood veneers. These veneers are chosen for their strength, uniformity, and structural integrity, forming the foundation of the LVL beams’ strength.

- Veneer Bonding: The selected veneers are then bonded together using heat-cured adhesives. This bonding process is meticulously controlled to ensure consistent bonding quality throughout the beam’s length.

- Layer Arrangement: The layers of veneers are strategically arranged to optimize load-bearing capacity and structural stability. The arrangement varies depending on the intended application and load requirements.

- Pressing and Curing: The layered veneers are subjected to high-pressure pressing, which compresses the layers and enhances the adhesion between them. Subsequent curing under controlled conditions solidifies the bond, contributing to the beams’ strength.

- Precision Cutting: After curing, the LVL beams are precisely cut to the desired dimensions. Advanced cutting techniques ensure dimensional accuracy, allowing for uniformity and predictability in their performance.

- Surface Finishing: Depending on the application, the LVL beams might undergo surface treatments such as sanding or coating to enhance their aesthetics and protect against environmental elements.

- Quality Control: Throughout the manufacturing process, strict quality control measures are in place. Non-destructive testing methods, such as ultrasound, are employed to detect any defects or inconsistencies within the beams.

- Eco-Friendly Practices: SENSO Framing places a strong emphasis on sustainability. The manufacturing process incorporates responsible sourcing of wood and optimization of resources to minimize waste, contributing to a greener construction industry.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

6 pallets |

20 CBM |

20000KGS |

19500KGS |

|

40 HQ |

12pallets |

40 CBM |

25000KGS |

24500KGS |

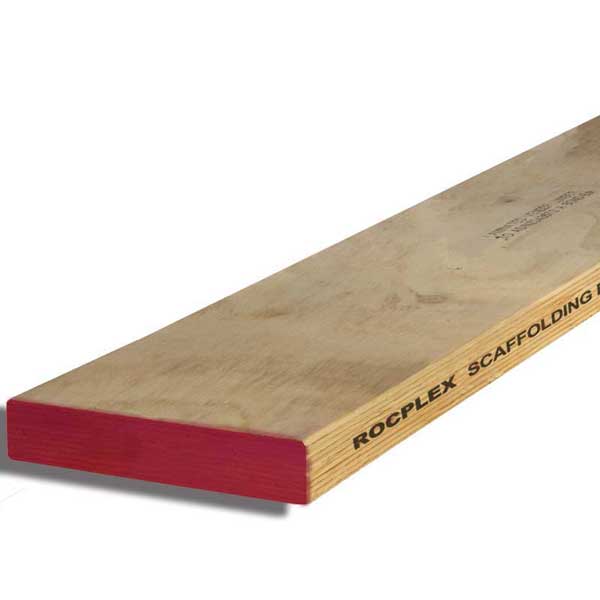

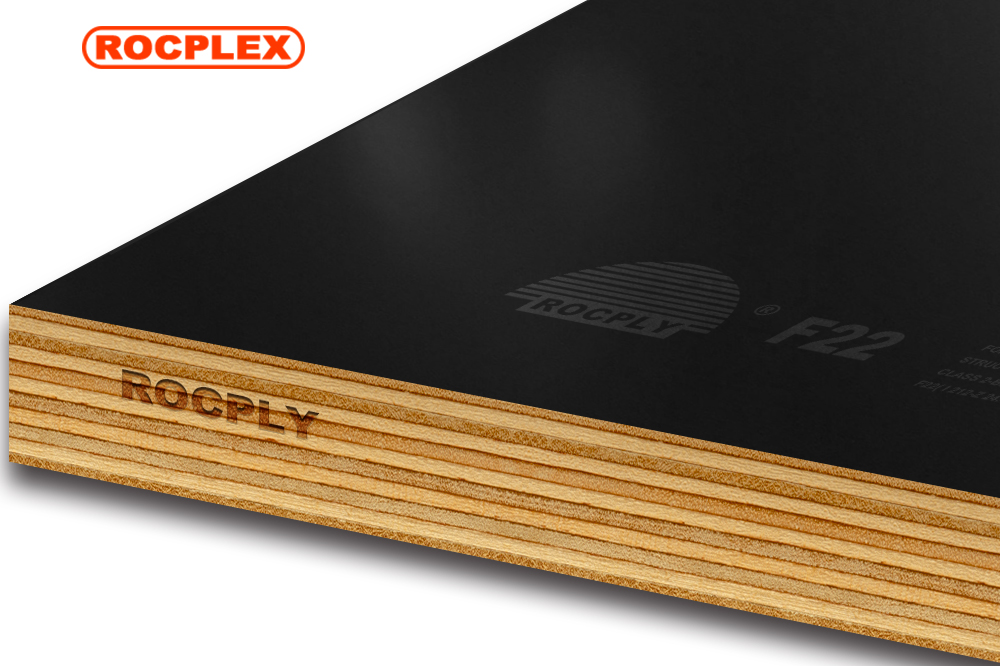

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying LVL and plywood boards.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

LVL Beams 150 x 45mm FAQ

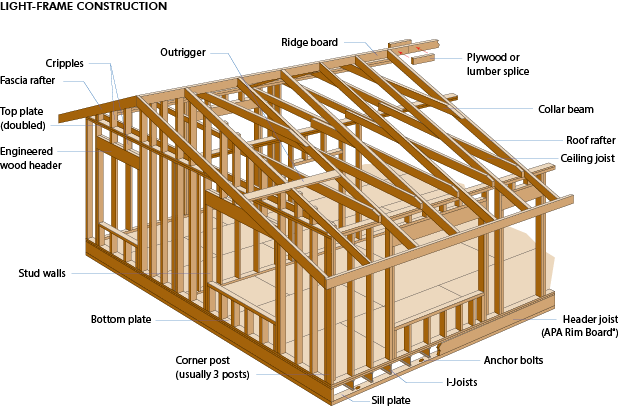

Q: What is the maximum span for LVL beams 150 x 45mm?

A: The maximum span for LVL beams 150 x 45mm will depend on the load requirements and the spacing of the beams. Generally, a structural engineer should be consulted to determine the appropriate span for your specific application.

Q: Can LVL beams be used for outdoor applications?

A: Yes, LVL beams can be used for outdoor applications as long as they are properly protected from moisture and weathering. A protective coating or waterproofing system may be necessary to ensure the longevity of the beams.

Q: How does LVL beams 150 x 45mm compare to traditional solid wood beams?

A: LVL beams have several advantages over traditional solid wood beams, including higher strength, greater resistance to warping and twisting, and more consistent sizing. They also have a more uniform appearance, which can be important for design considerations.

Q: How are LVL beams 150 x 45mm installed?

A: LVL beams are typically installed using hangers or brackets attached to the structure. The beams should be properly supported and anchored to ensure that they can bear the required load.

Q: Can LVL beams 150 x 45mm be cut or drilled?

A: Yes, LVL beams can be cut or drilled using standard woodworking tools. However, it is important to follow manufacturer guidelines and use appropriate safety equipment to avoid damage to the beam or injury to the user.