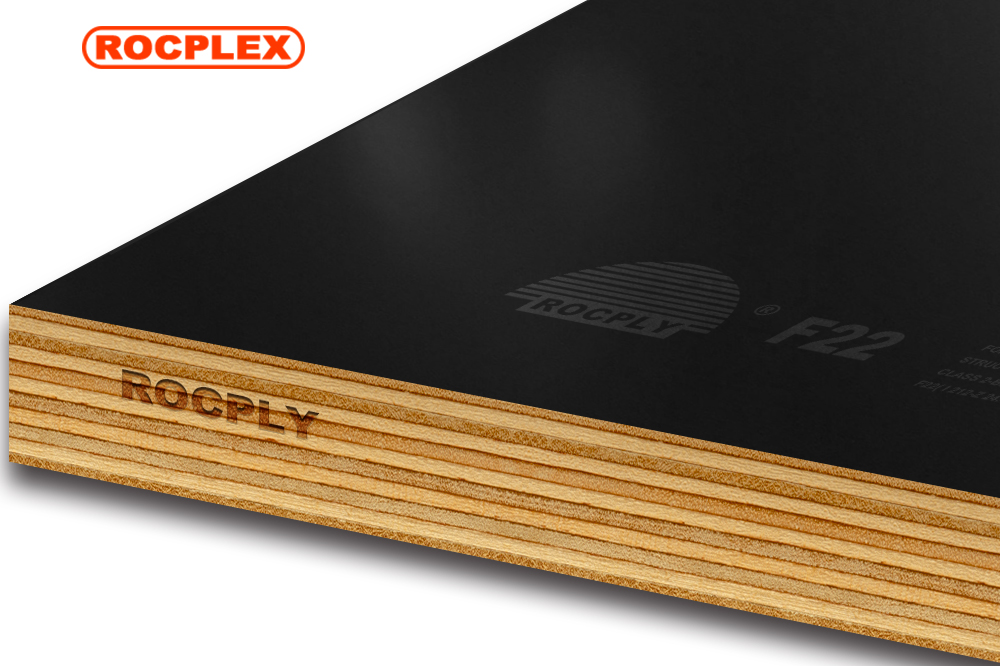

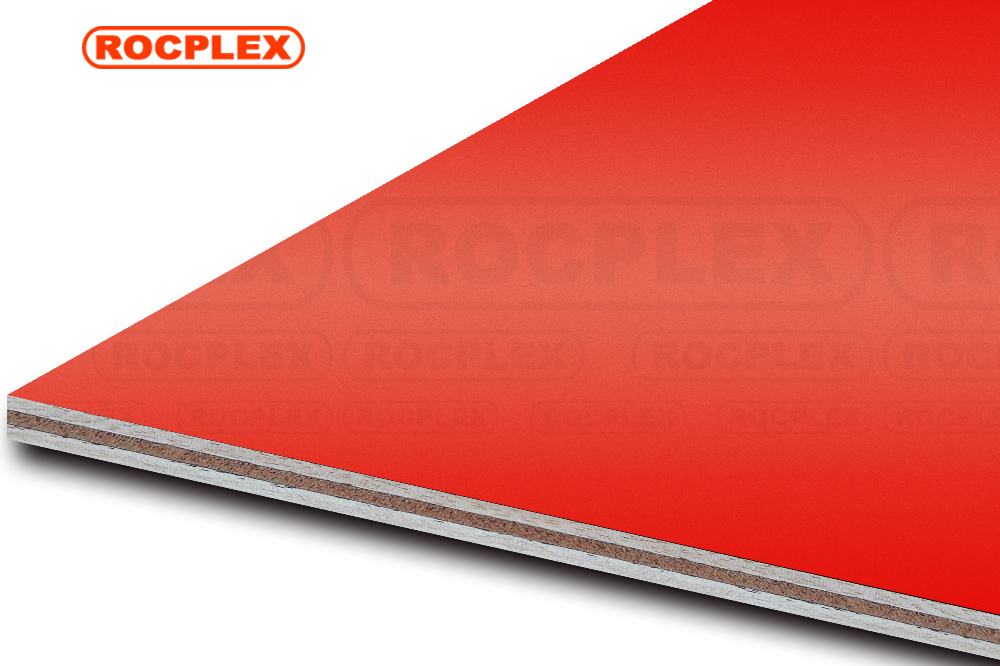

Packing Plywood for Secure Shipping and Storage

When it comes to packaging and protecting goods for shipping and storage, choosing the right material is crucial. ROCPLEX Packing plywood, a specialized variant of plywood, has become a staple in the world of logistics due to its durability, strength, and cost-effectiveness.

|

Face / Back: Okoume Bintangor Pine Poplar Birch Pencil cedar |

|

Grade: BB/CC C/D D/E E/F |

|

Core: Poplar core / Combi core / Hardwood core / Pine core / Birch core |

|

Glue: E0 glue, E1 glue, E2 glue, WBP glue, MR glue |

|

Thickness: 4-28mm (normal: 3mm, 6mm, 9mm, 12mm, 15mm, 18mm, 21mm) |

|

Specification: 1220mmX2440mm, 1250mmX2500mm, 915mmX1830mm, 610mmX2440mm , 610mmX2500mm |

|

Moisture Content: 8-14% |

|

Density: 530-780kg/m3 |

|

Container type |

Pallets |

Volume |

Gross weight |

Net weight |

|

20 GP |

8 pallets |

21 CBM |

13000KGS |

12500KGS |

|

40 GP |

16 pallets |

42 CBM |

25000KGS |

24500KGS |

|

40 HQ |

18 pallets |

53 CBM |

28000KGS |

27500KGS |