Structural LVL E14 Engineered Wood LVL Beams 130 x 45mm H2S Treated SENSO Framing LVL F17

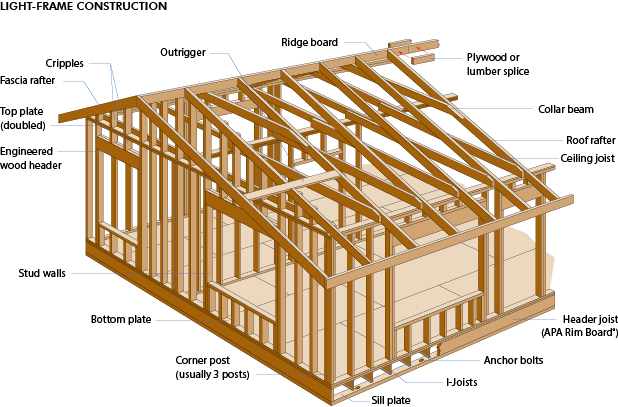

Structural LVL (Laminated Veneer Lumber) E14 Engineered Wood is a type of engineered wood product commonly used in construction and building projects. LVL is made by bonding together multiple layers of thin wood veneers with adhesive, which creates a strong and dimensionally stable material.

The “E14” designation refers to the product’s strength rating, indicating its modulus of elasticity (E) and bending strength (14). This rating is used to determine the load-bearing capacity and structural performance of the LVL beams.

The dimensions “130 x 45mm” specify the width and depth of the LVL beams. In this case, the beam has a width of 130mm and a depth of 45mm. These dimensions are important considerations for determining the beam’s load-carrying capacity and suitability for specific applications.

The “H2S Treated” indicates that the LVL beams have been treated with H2S (Hydrogen Sulfide) preservative. This treatment provides protection against fungal decay and insect attack, making the beams suitable for outdoor and above-ground applications where they may be exposed to moisture or pests.

SENSO Structural LVL Features & Benefits:

- According to the client’s requirement to produce.

- True Sourced from environmentally sustainable plantation timber.

- Veneers are bonded together using a type ‘A’ (marine) bond, which has proven performance for in excess of 50 years

- Quick assembly due to the ready-to-use prefab panels and installation of high-strength frames without heavy lifting equipment.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

VL Beams 130 x 45mm FAQ

Q: What is an LVL beam?

A: LVL stands for Laminated Veneer Lumber. It is an engineered wood product made by bonding thin wood veneers together under heat and pressure to create a strong and durable beam.

Q: What are LVL beams 130 x 45mm used for?

A: LVL beams 130 x 45mm are commonly used for load-bearing applications such as beams, joists, and lintels in construction projects.

Q: What are the advantages of using LVL beams over traditional solid wood beams?

A: LVL beams offer several advantages over traditional solid wood beams. They have a higher strength-to-weight ratio, which means they can support greater loads with less material. LVL beams are also more dimensionally stable than solid wood beams, which reduces the risk of warping and twisting over time. Additionally, LVL beams are more uniform in strength and quality, which allows for more consistent performance in construction projects.

Q: How do you install LVL beams?

A: The installation process for LVL beams is similar to that of traditional solid wood beams. The beams should be properly supported and spaced according to building codes and engineering specifications. The ends of the beams should also be properly supported to prevent sagging or bending.

Q: How long do LVL beams last?

A: The lifespan of LVL beams will depend on several factors such as the environmental conditions they are exposed to and the level of maintenance they receive. However, with proper installation and maintenance, LVL beams can last for many years.

Q: Are LVL beams more expensive than traditional solid wood beams?

A: The cost of LVL beams may be higher than traditional solid wood beams, but they offer greater strength and durability, which can lead to long-term cost savings in terms of reduced maintenance and repair costs.