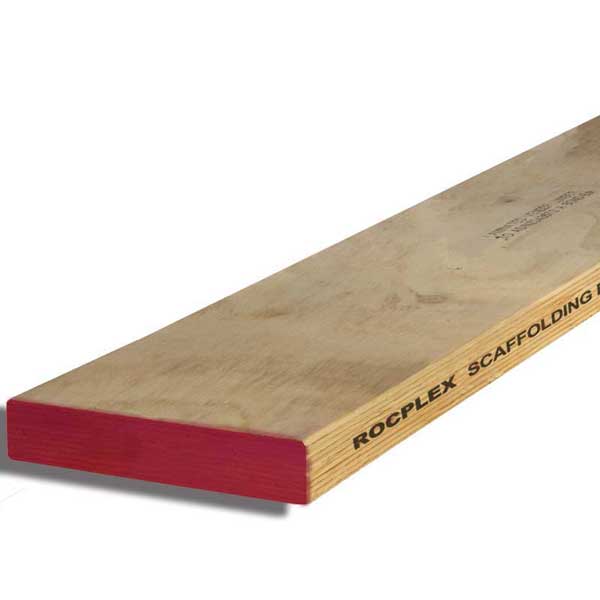

Top-Notch LVL Beams 140 x 45mm: Strength and Versatility Unleashed

Step into a new era of construction excellence with 140 x 45mm LVL beams. These beams transcend traditional materials, offering a unique blend of strength and versatility for modern projects. With a commitment to quality and innovation, these engineered wood marvels provide unmatched load-bearing capabilities, ensuring stability in diverse applications. From soaring architectural achievements to essential structural support, LVL beams empower construction with their reliability and adaptability. Discover how these beams redefine limits, setting a new standard for construction possibilities while demonstrating an unwavering dedication to top-notch performance.

Applications and Benefits:

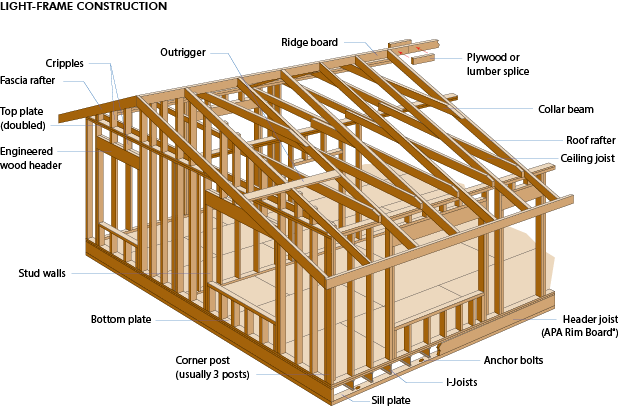

- Interior Load-Bearing Elements: LVL beams are well-suited for crafting load-bearing interior walls and partitions, ensuring stability and structural robustness even in confined spaces.

- Dependable Floor and Roof Systems: From constructing floor frameworks to roof structures, LVL beams excel in delivering steadfast support, minimizing deflection, and ensuring long-term stability.

- Supporting Openings: Their strength positions LVL beams as reliable choices for supporting door and window headers, distributing weight evenly and reducing strain on adjacent structures.

Advantages in Modern Construction:

- Design Flexibility: LVL beams’ consistent strength and stability empower architects and builders to experiment with various design concepts, including extended spans and innovative layouts.

- Sustainability Focus: Crafted from sustainable wood sources, LVL beams align with eco-conscious construction practices and responsible forestry management.

- Minimal Waste: The manufacturing process of LVL beams is engineered to minimize waste, promoting sustainable construction methods.

Embracing 140 x 45mm LVL beams showcases a dedication to contemporary construction advancements. Their durability, versatility, and structural strength position them as essential elements across various construction scenarios. From fortifying load-bearing interiors to constructing robust floors, roofs, and facilitating door and window openings, LVL beams epitomize the fusion of engineering ingenuity and sustainable building ethos.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying LVL and plywood boards.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

LVL Beams 140 x 45mm FAQ

Q: What is the maximum span for LVL beams 140 x 45mm?

A: The maximum span for LVL beams will depend on the load requirements and the spacing of the beams. Generally, a structural engineer should be consulted to determine the appropriate span for your specific application.

Q: Can LVL beams 140 x 45mm be used for outdoor applications?

A: Yes, LVL beams can be used for outdoor applications as long as they are properly protected from moisture and weathering. A protective coating or waterproofing system may be necessary to ensure the longevity of the beams.

Q: How does LVL beam 140 x 45mm compared to traditional solid wood beams?

A: LVL beams have several advantages over traditional solid wood beams, including greater strength and stability, more consistent sizing, and resistance to warping and twisting. They also have a more uniform appearance, which can be important for design considerations.

Q: How are LVL beams 140 x 45mm installed?

A: LVL beams are typically installed using hangers or brackets attached to the structure. The beams should be properly supported and anchored to ensure that they can bear the required load.

Q: Can LVL beams 140 x 45mm be cut or drilled?

A: Yes, LVL beams can be cut or drilled using standard woodworking tools. However, it is important to follow manufacturer guidelines and use appropriate safety equipment to avoid damage to the beam or injury to the user.