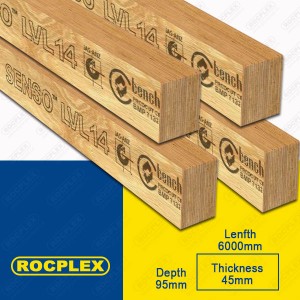

Structural LVL E14 Engineered Wood LVL Beams 90 x 45mm H2S Treated SENSO Framing LVL F17

Introducing our Structural LVL E14 Engineered Wood LVL Beams 90 x 45mm H2S Treated SENSO Framing LVL F17, a reliable and versatile solution for your structural framing needs.

These Laminated Veneer Lumber (LVL) beams are designed to provide exceptional strength and stability in various construction applications. With dimensions of 90 x 45mm, they offer a sturdy foundation for your framing projects.

Our LVL beams are engineered using high-quality wood veneers, carefully laminated together to create a robust and durable product. The E14 grade signifies its high structural performance, making it suitable for demanding load-bearing applications.

To enhance its resistance to fungal decay and termite attacks, the LVL beams are treated with H2S (Hazard Level 2 Softwood) treatment. This treatment ensures long-term durability, even in humid and challenging environments.

The SENSO framing LVL F17 features reliable structural properties, meeting or exceeding the F17 standard. This ensures the LVL beams can withstand heavy loads and provide excellent stability and support for your construction projects.

These LVL beams offer ease of installation, thanks to their uniform shape and consistent dimensions. They are lightweight compared to traditional solid timber, making them easier to handle and transport on-site.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

6 pallets |

20 CBM |

20000KGS |

19500KGS |

|

40 HQ |

12pallets |

40 CBM |

25000KGS |

24500KGS |

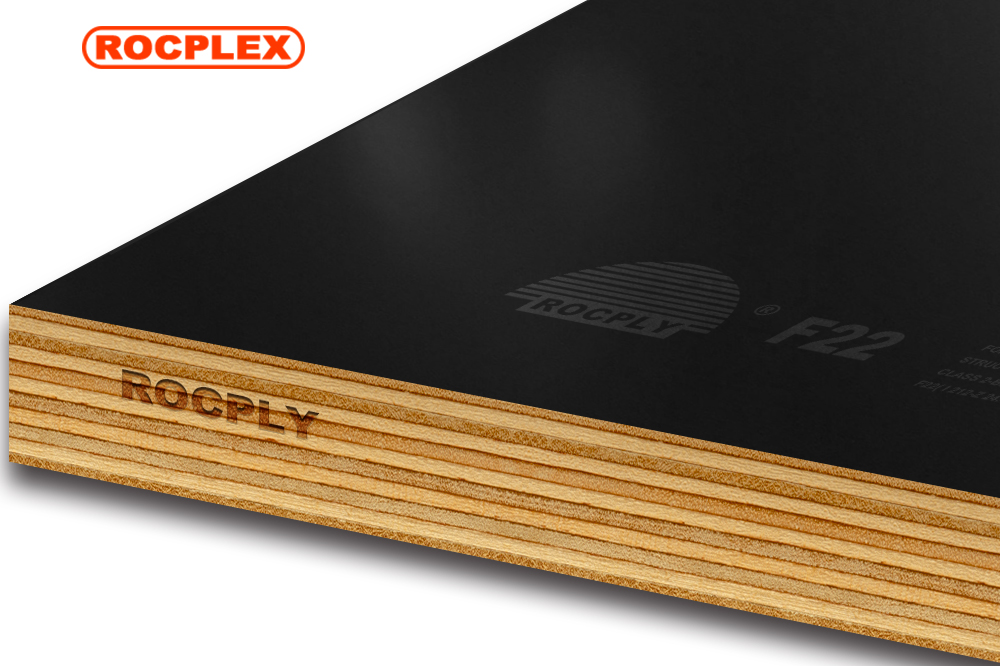

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding Chinese plywood.

Structural LVL E14 Engineered Wood FAQ

Q: What does LVL E14 stand for?

A: LVL E14 stands for Laminated Veneer Lumber with an E14 grade. The “E” in E14 stands for modulus of elasticity, which is a measure of a material’s stiffness, while the “14” indicates the minimum bending stress the material can withstand.

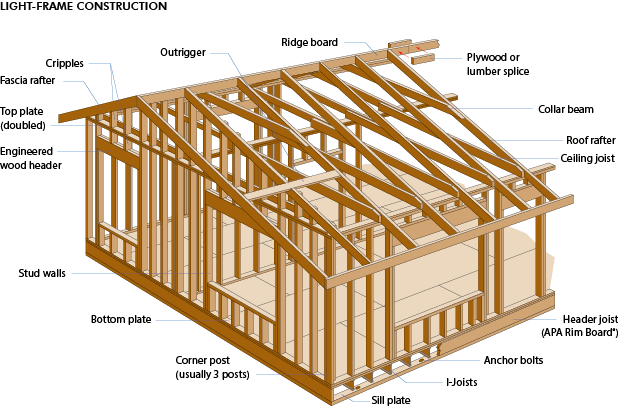

Q: What is LVL E14 used for?

A: LVL E14 is commonly used for heavy-duty structural applications such as beams, headers, and rafters in construction. Its strength, stability, and resistance to warping make it an attractive alternative to traditional wood beams in many applications.

Q: How is LVL E14 made?

A: LVL E14 is made by layering thin wood veneers together and bonding them with adhesives under heat and pressure. The veneers are arranged in a way that maximizes their strength and stiffness, resulting in a product that is much stronger than traditional solid wood beams.

Q: What are the advantages of LVL E14 over traditional wood beams?

A: Some of the advantages of LVL E14 over traditional wood beams include its superior strength-to-weight ratio, dimensional stability, and uniformity. It is also resistant to warping, splitting, and shrinking, making it an ideal choice for high-stress applications.

Q: What are the disadvantages of LVL E14?

A: The main disadvantage of LVL E14 is that it can be more expensive than traditional wood beams. Additionally, it is not as aesthetically pleasing as solid wood and may require additional finishing to achieve the desired look.