Versatile LVL Beams 240 x 65mm: Engineered Wood Solutions

LVL Beams 240 x 65mm H2S treated Wood veneers are peeled and laminated together under certain circumstances to create LVL. Each wood veneer has its qualities determined via testing, thus numerous combinations of veneers may be made depending on the desired attributes of the finished product. The veneers are joined together using heat, adhesive, and pressure. As a result, the final product is stable, incredibly predictable, and homogeneous to use for SESNSO framing.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

6 pallets |

20 CBM |

20000KGS |

19500KGS |

|

40 HQ |

12pallets |

40 CBM |

25000KGS |

24500KGS |

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying LVL and plywood boards.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

LVL Beams 240 x 65mm FAQ

Q: What is LVL and how is it made?

A: LVL stands for Laminated Veneer Lumber. It is made by bonding together multiple layers of thin wood veneers with adhesive. The resulting product is a strong and durable beam that is able to support heavy loads.

Q: What are the advantages of using LVL beams 240 x 65mm?

A: LVL beams 240 x 65mm have several advantages over traditional solid wood beams. They are stronger and more consistent in strength and size, which means they can support heavier loads without warping or bending. They are also more environmentally friendly than traditional wood beams, as they are made from sustainably harvested wood and can be recycled at the end of their lifespan.

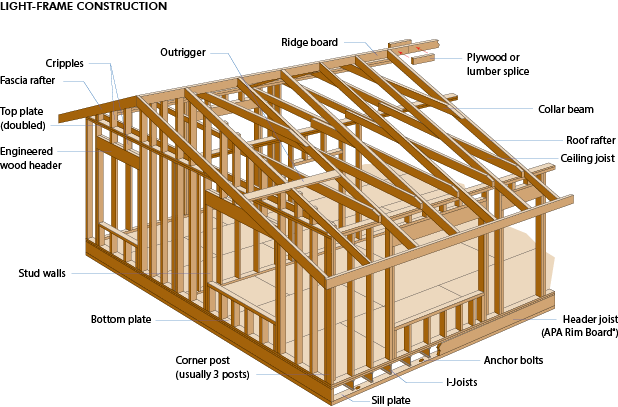

Q: What are the typical applications of LVL beams 240 x 65mm?

A: LVL beams 240 x 65mm are commonly used as load-bearing beams in residential and commercial construction projects, particularly in floor and roof framing applications. They can also be used in other applications such as beams for pergolas or gazebos.

Q: How do I determine what size LVL beam I need for my project?

A: The size of the LVL beam you need will depend on several factors, including the span of the beam, the load it will need to support, and the type of construction you are doing. It is important to consult with a structural engineer or building professional to determine the appropriate size and type of LVL beam for your project.

Q: Can LVL beams be cut to size on-site?

A: LVL beams can be cut to size on-site using standard woodworking tools. However, it is important to follow the manufacturer’s guidelines for cutting and installing LVL beams to ensure that they are installed correctly and safely.