Structural LVL E13 Engineered Wood LVL Beams 400 x 65mm H2S Treated SENSO Framing LVL 13

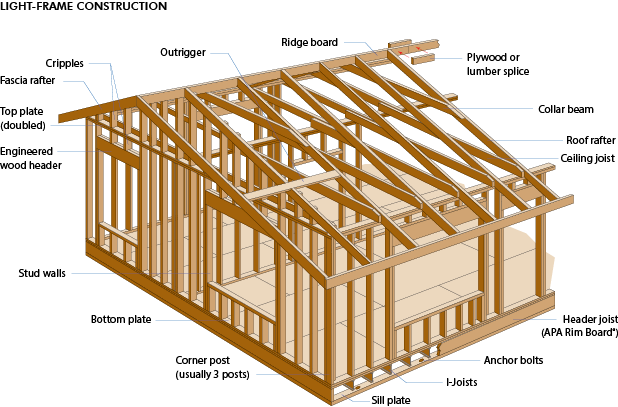

Introducing our premium Structural LVL E13 Engineered Wood LVL Beams 400 x 65mm H2S Treated SENSO Framing LVL 13. These beams are designed to provide exceptional strength, durability, and versatility for a wide range of construction applications.

Crafted using laminated veneer lumber (LVL) technology, these beams ensure consistent performance and unwavering structural integrity. With a width of 400mm and a thickness of 65mm, they offer superior load-bearing capabilities, making them ideal for heavy-duty framing and structural projects.

Refer to the Specifications below for specifications on the major types of LVL formwork supplied by ROCPLEX or contact us to discuss further your needs.

SENSO Structural LVL Features & Benefits:

- Dimensions: Wide width of 400mm and thickness of 65mm, providing excellent load-bearing capabilities for heavy-duty construction projects.

- H2S Treated: Beams undergo H2S treatment to enhance resistance against decay, rot, and insect attacks.

- SENSO Framing LVL 13: Compliant with industry standards, ensuring quality and performance.

- Superior Strength: Designed for heavy-duty framing and structural applications, offering exceptional load-bearing capacity.

- Enhanced Durability: H2S treatment provides increased resistance to decay, rot, and insects, prolonging the lifespan of the beams.

- Versatility: Suitable for various framing and structural projects, accommodating diverse construction needs.

- Dimensional Stability: Engineered wood construction minimizes warping, twisting, or splitting, ensuring long-term performance.

- Easy Installation: Uniform dimensions and predictable structural properties simplify handling and installation.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

6 pallets |

20 CBM |

20000KGS |

19500KGS |

|

40 HQ |

12pallets |

40 CBM |

25000KGS |

24500KGS |

Meanwhile, we also can supply you the formwork system accessories, commercial plywood, film-faced plywood, etc.

We are especially professional in supplying LVL and plywood boards.

Please contact our sales team for more detailed information regarding ROCPLEX – SENSO Structural LVL.

LVL Beams 400 x 65mm FAQ

Q: What are LVL beams used for?

A: LVL beams are used for structural support in a variety of construction projects, including commercial buildings, bridges, and residential homes.

Q: How strong are LVL beams?

A: LVL beams are very strong and can support heavy loads. The strength of an LVL beam depends on its size and the number of veneers used to create it.

Q: Can LVL beams be used for outdoor applications?

A: Yes, LVL beams can be used for outdoor applications, but they should be treated with a weather-resistant coating to protect them from moisture and other environmental factors.

Q: Are LVL beams more expensive than solid wood beams?

A: LVL beams can be more expensive than solid wood beams, but they offer several advantages, including greater strength and dimensional stability, which can make them a cost-effective choice in the long run.

Q: How are LVL beams installed?

A: LVL beams are installed using traditional framing methods, such as bolting, nailing, or screwing them to other structural members. It is important to follow the manufacturer’s installation instructions to ensure the proper installation of LVL beams.