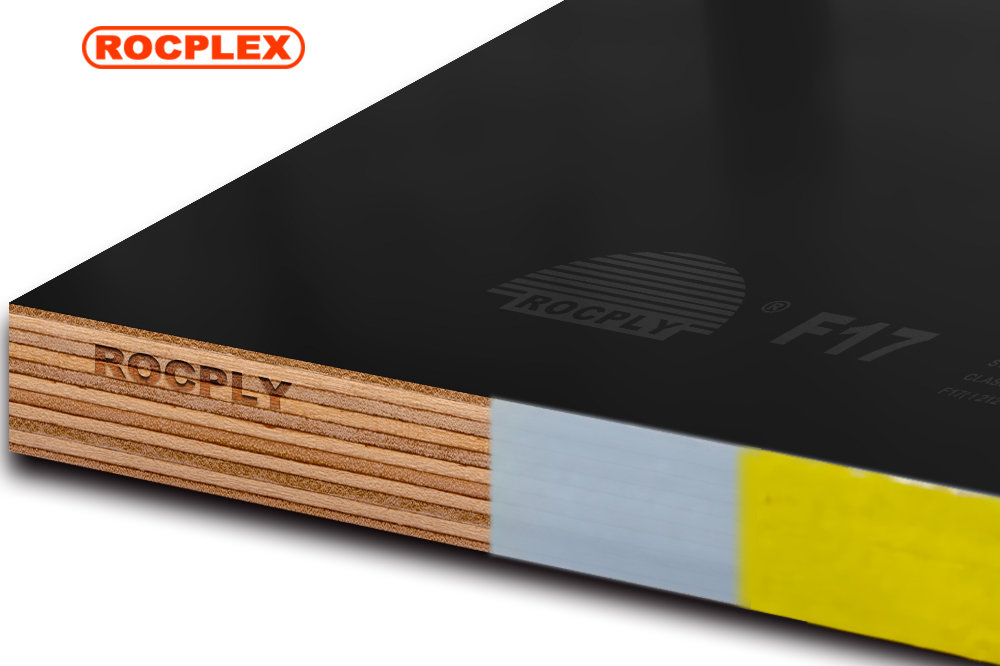

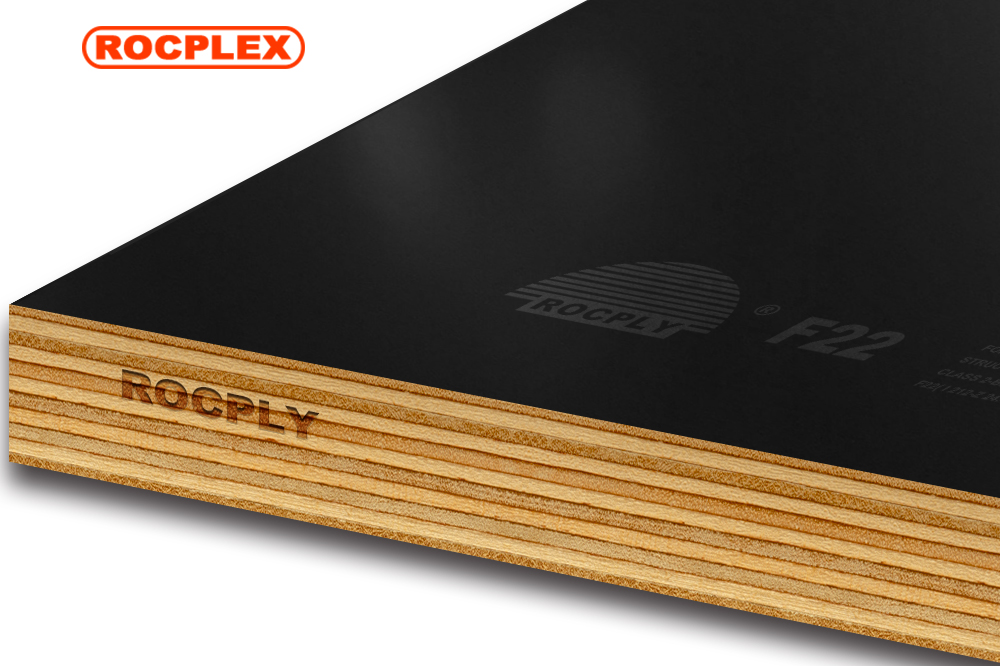

ROCPLY Formply F17 2400 x 1200 x 17mm Formwork Plywood AS 6669 Certified

Introducing ROCPLY® Formply F17, the ultimate choice for top-quality former products. With its outstanding performance and dual certifications from BENCHMARK and CERTMARK, it is recognized as a premium option that meets the highest standards of quality and durability.

ROCPLY® Formply F17 is trusted by contractors and builders worldwide for its exceptional strength and durability. Whether you’re constructing foundations, walls, columns, or bridges, this reliable and versatile former product delivers unparalleled performance and value.

With its precise size and thickness, ROCPLY® Formply F17 offers optimal availability to cater to various construction needs. Its robust construction ensures it can withstand the rigors of demanding construction projects, providing reliable support and stability.

As the only dual-certified former product, ROCPLY® Formply F17 holds both the AS 6669 and AS/NZS 2269 standard certifications. This distinction further highlights its compliance with industry benchmarks, ensuring peace of mind and confidence in its quality.

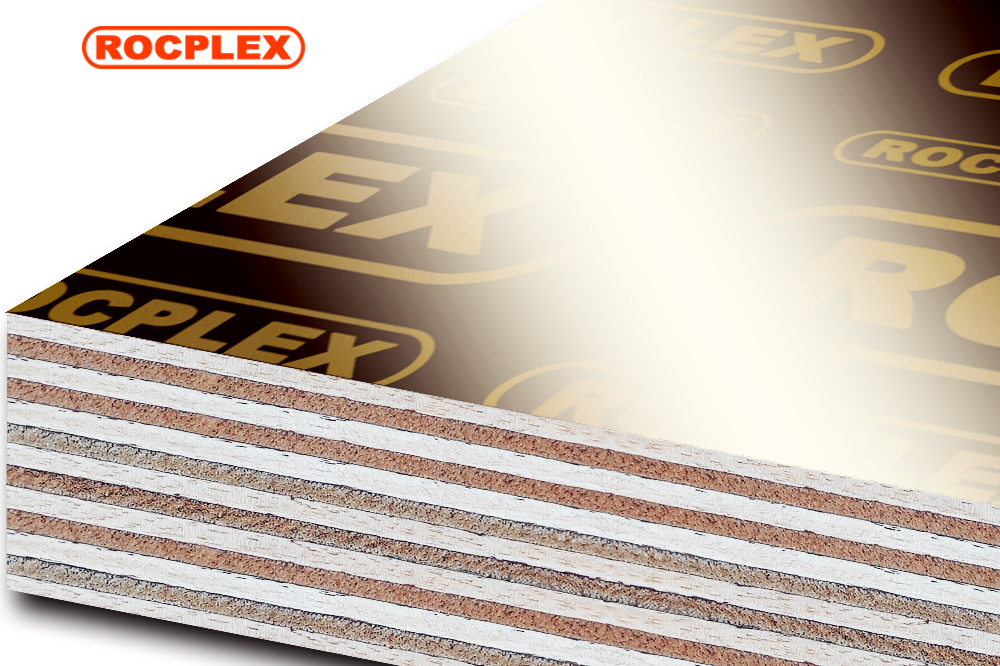

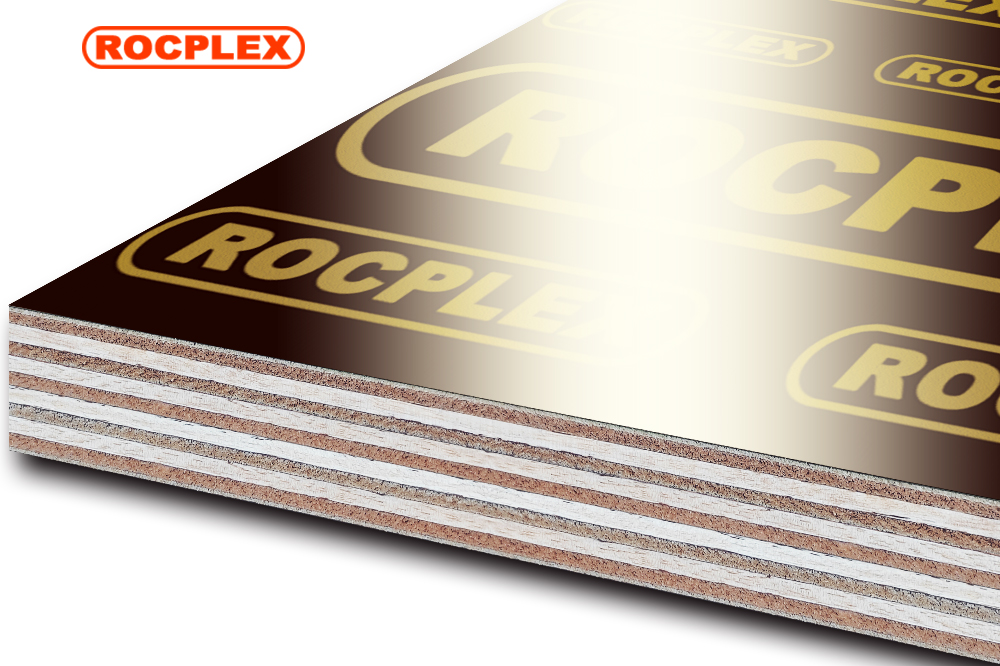

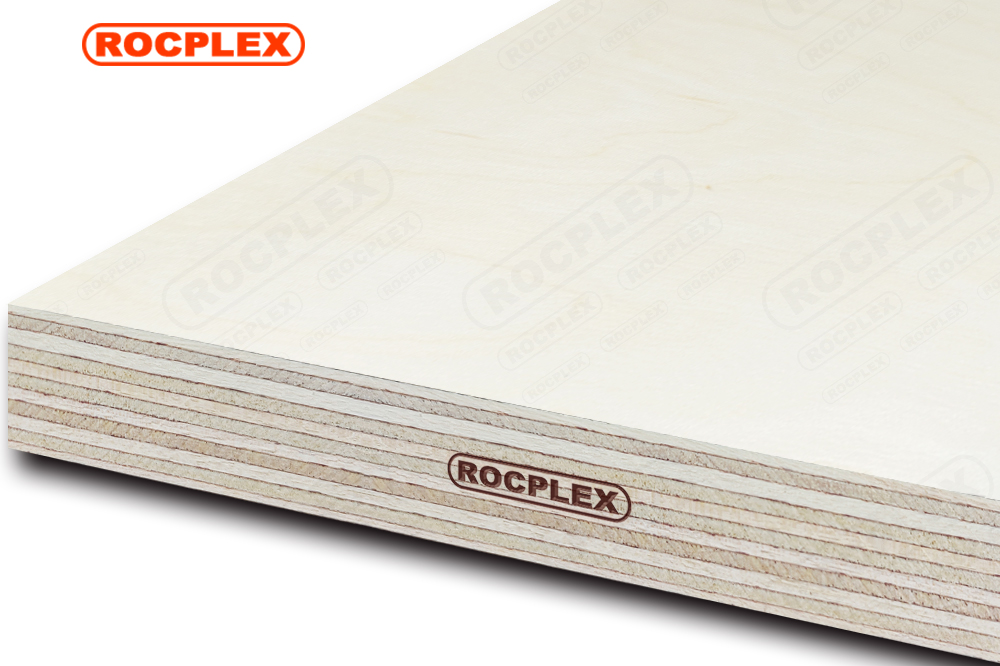

ROCPLY F17 Formply stands out with its high-grade full hardwood veneers that are meticulously bonded using a specially formulated super E0 waterproof adhesive. This custom adhesive ensures exceptional bonding strength, resulting in a plywood product that is both robust and stable.

To further enhance its quality, ROCPLY F17 Formply undergoes a manufacturing process that incorporates oblique joint and hot-melt splicing technology. This technique effectively eliminates any potential gaps between the veneers, ensuring a solid, durable, and reliable plywood product. It is precisely engineered for concrete formwork applications, providing the strength and stability required for demanding construction projects.

ROCPLY F17 Formply takes pride in its commitment to responsible forestry practices. The veneer used in its production is sourced from certified Forest Stewardship Council (FSC) forests, promoting sustainability and eco-friendly manufacturing processes.

ROCPLY F17 For Strong, Stable, Concrete Formwork

| Stress Grade | Sheet Size (mm) | Thicknesses (mm) | Weight (kg/sheet) | Parallel to face grain | Perpendicular to face grain |

Core Materials |

Packing Unit (sheets) |

||

| Moment of inertia | Section modulus | Moment of inertia | Section modulus | ||||||

| I(mm4/mm) | Z(mm3/mm) | I(mm4/mm) | Z(mm3/mm) | ||||||

| F17 ROCPLY | 1800×1200 | 12, 17, 19 & 25 | 24 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

| F17 ROCPLY | 2400×1200 | 12, 17, 19 & 25 | 32 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

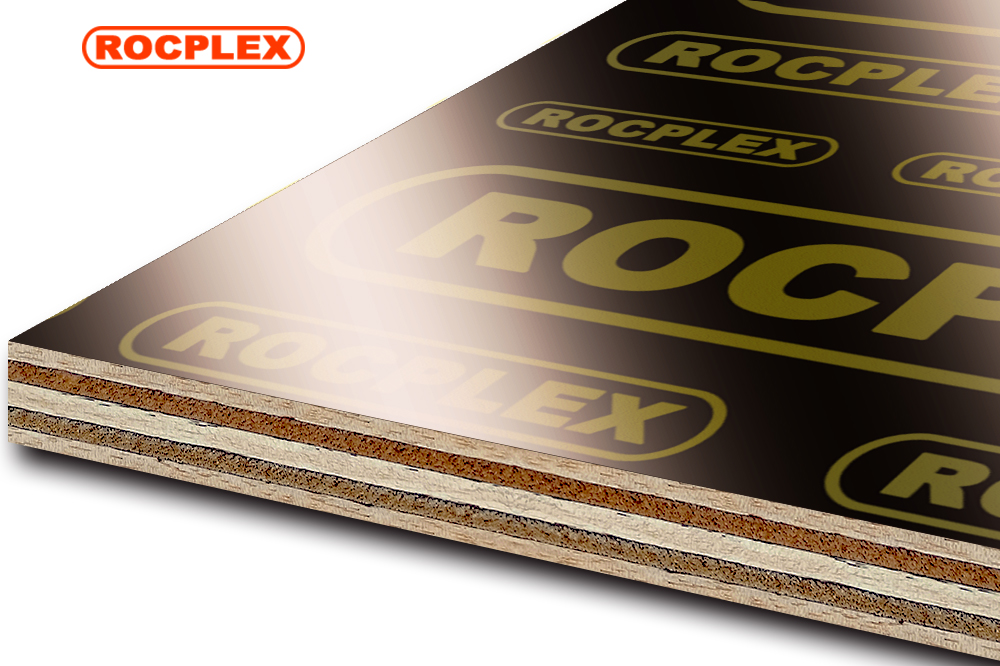

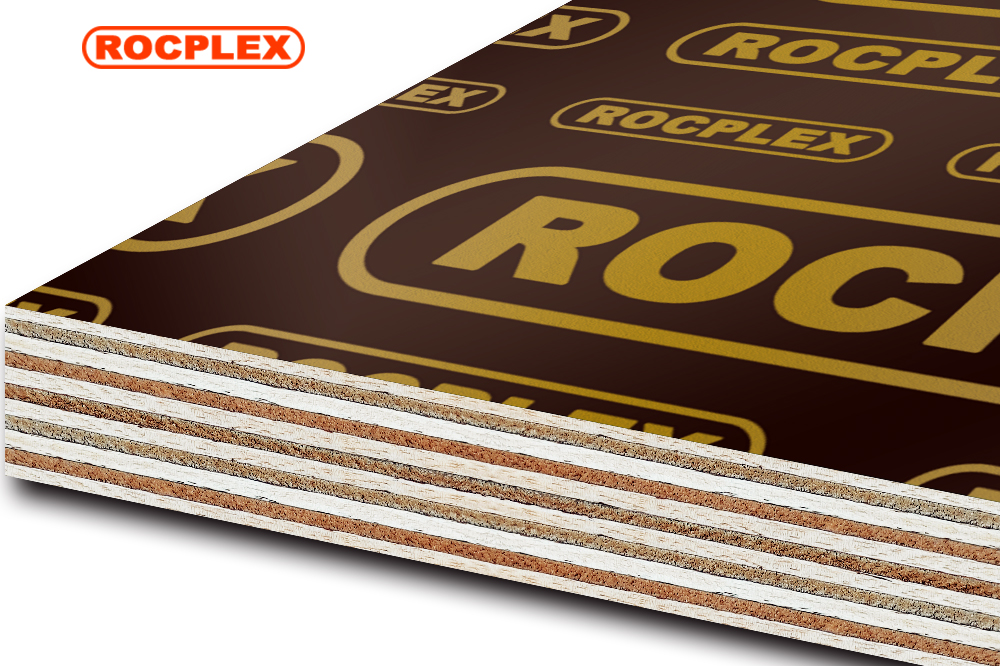

Surfaces

Structure

Bonding

Sealing

|

1 |

Face and Back |

ROCPLY Special Custom Film |

|

2 |

Grade |

AA grade |

|

3 |

Core Materials |

Full Hardwood Core |

|

4 |

Glue Choose |

A bond Waterproof Super E0 Glue |

|

5 |

Thickness |

6-28mm(normal thickness:12mm, 17mm, 19mm, 25mm) |

|

6 |

Specification |

1800mmX1200mm, 2400mmX1200mm 1800mmX600mm , 2400mmX600mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

630-680 kg/ m3 |

ROCPLY Formply Advantage

Features:

- ROCPLY Formply F17 is made from high-quality hardwood veneers that are bonded with waterproof glue, providing durability and resistance to wear and tear.

- The formwork plywood has a thickness of 17mm, making it sturdy and able to support heavy loads.

- ROCPLY Formply F17 is AS 6669 certified, ensuring that it meets Australian standards for formwork plywood.

- The plywood is treated with special chemicals that make it resistant to moisture, rot, and termites, ensuring a long lifespan.

- ROCPLY Formply F17 has a smooth surface that allows for easy release of formwork, reducing the need for extra release agents and saving time and money.

- The formwork plywood has a high strength-to-weight ratio, making it easy to handle and transport.

Benefits:

- ROCPLY Formply F17 is an ideal choice for construction projects that require sturdy, reliable formwork.

- The plywood’s high-quality construction ensures that it can withstand heavy loads and resist wear and tear, making it a durable and long-lasting option.

- ROCPLY Formply F17’s AS 6669 certification ensures that it meets Australian standards for formwork plywood, providing peace of mind to builders and contractors.

- The plywood’s resistance to moisture, rot, and termites makes it suitable for use in outdoor construction projects, ensuring that it can withstand harsh weather conditions and remain in good condition.

- ROCPLY Formply F17’s smooth surface allows for easy release of formwork, reducing the need for extra release agents and saving time and money.

- The formwork plywood’s high strength-to-weight ratio makes it easy to handle and transport, reducing the risk of injury and increasing efficiency on the job site.

| ROCPLY Fomply Save cost | ||

| Be special for phenolic glue and film | The family can be disassembled and used repeatedly for both faces, saving 25% of the cost. | |

| Optimization for the special grade of core | ||

| Be special for adhesive | ||

| ROCPLY Fomply Shorten duration | ||

| Excellent effect of de-molding | Shorten 30% of the duration. | |

| Avoid the reconstruction of the wall | ||

| Be easy to incise and blend | ||

| ROCPLY Formply The high quality of casting | ||

| The flat and smooth faces | The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. | |

| The structure of waterproof and breathability | ||

| The edges are polished carefully | ||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

10-12 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

20-27 pallets |

43 CBM |

25500KGS |

26000KGS |

Meanwhile, we also can supply you the formwork system accessories, Edge LVL, Plywood, family, etc.

We are especially professional in supplying structural and formwork building materials.

Please contact our sales team for more detailed information regarding ROCPLY F17 formerly.

2400 x 1200 x 17mm Formwork Plywood AS 6669 Certified FAQ

Q: What is the maximum load capacity of this plywood?

A: The maximum load capacity of 2400 x 1200 x 17mm Formwork Plywood AS 6669 Certified will depend on several factors such as the spacing of the supports, the thickness of the plywood, and the type of load that it is supporting. However, it is generally designed and manufactured to withstand heavy loads.

Q: Can this plywood be reused?

A: Yes, this plywood can be reused multiple times, making it a cost-effective option for concrete formwork applications. However, the number of times it can be reused will depend on several factors such as the level of care taken during installation and removal, and the extent of any damage sustained during use.

Q: Is this plywood waterproof?

A: Yes, 2400 x 1200 x 17mm Formwork Plywood AS 6669 Certified is highly resistant to water and moisture due to its waterproof resin adhesive and high-quality veneers. This makes it an ideal choice for concrete formwork applications where exposure to water and moisture is common.

Q: What is the difference between AS 6669 certified plywood and non-certified plywood?

A: AS 6669 certified plywood has been rigorously tested and evaluated to meet specific performance requirements for use in concrete formwork applications. This includes resistance to water, durability, and strength. Non-certified plywood may not have undergone such testing and may not meet the same performance requirements.

Q: Can this plywood be cut to size?

A: Yes, 2400 x 1200 x 17mm Formwork Plywood AS 6669 Certified can be easily cut to size using standard cutting tools. However, it is recommended to use appropriate safety measures such as wearing protective eyewear and gloves when cutting the plywood.